Oxygen-doped porous carbon nitride nanosheets and preparation method thereof

A carbon nitride and oxygen doping technology, applied in chemical instruments and methods, nanotechnology, nitrogen compounds, etc., can solve the problems of high cost, complex preparation process, insufficient photocatalytic performance improvement of materials, etc., and achieve low cost and experimental results. The effect of strong operability and excellent photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention relates to a preparation method of oxygen-doped porous carbon nitride nanosheets, using carbon-nitrogen precursors, ethanol and water as raw materials, firstly adopting ethanol-assisted hydrothermal treatment of conventional carbon-nitrogen precursors to prepare modified precursors; then The above-mentioned modified precursor is calcined at a high temperature to obtain oxygen-doped porous carbon nitride nanosheets.

[0027] Specifically follow the steps below:

[0028] Step 1, preparation of modified precursor:

[0029] Weigh the carbon-nitrogen precursor, put it into a clean polytetrafluoroethylene liner, and then add ethanol and deionized water; the mass ratio of the carbon-nitrogen precursor to deionized water is 1:100-1:1, ethanol The volume ratio to deionized water is 1:500~2:1. After stirring evenly, cover the lid and move it into the corresponding stainless steel reactor jacket, and keep it in an oven at 150~200°C for 2~20h. After cooling in the f...

Embodiment 1

[0035] Step 1, according to the mass ratio of melamine and deionized water is 1:10, the volume ratio of ethanol and deionized water is 1:80, add melamine, ethanol, deionized water to the clean polytetrafluoroethylene lining and mix, Stir evenly; cover the above polytetrafluoroethylene liner with a lid, put it into the corresponding stainless steel jacket, tighten it, put it in an oven, and keep it warm at 200 ° C for 6 hours; after cooling with the furnace, the obtained solid-liquid mixture is deionized Water and absolute ethanol were washed by centrifugation for 5 times, and then dried in an oven at 60°C for 20 hours to obtain the modified melamine precursor.

[0036] Step 2, put the precursor obtained in step 1 into an alumina crucible, cover it; heat preservation at 550°C for 2 hours, and calcine at a heating rate of 0.5°C / min to obtain porous carbon nitride nanosheets.

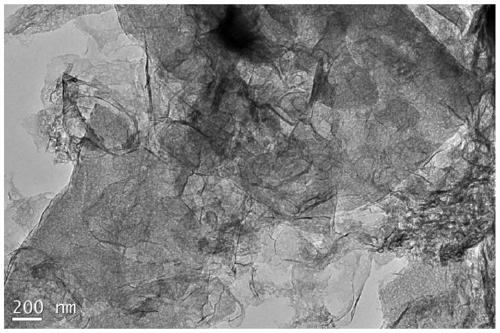

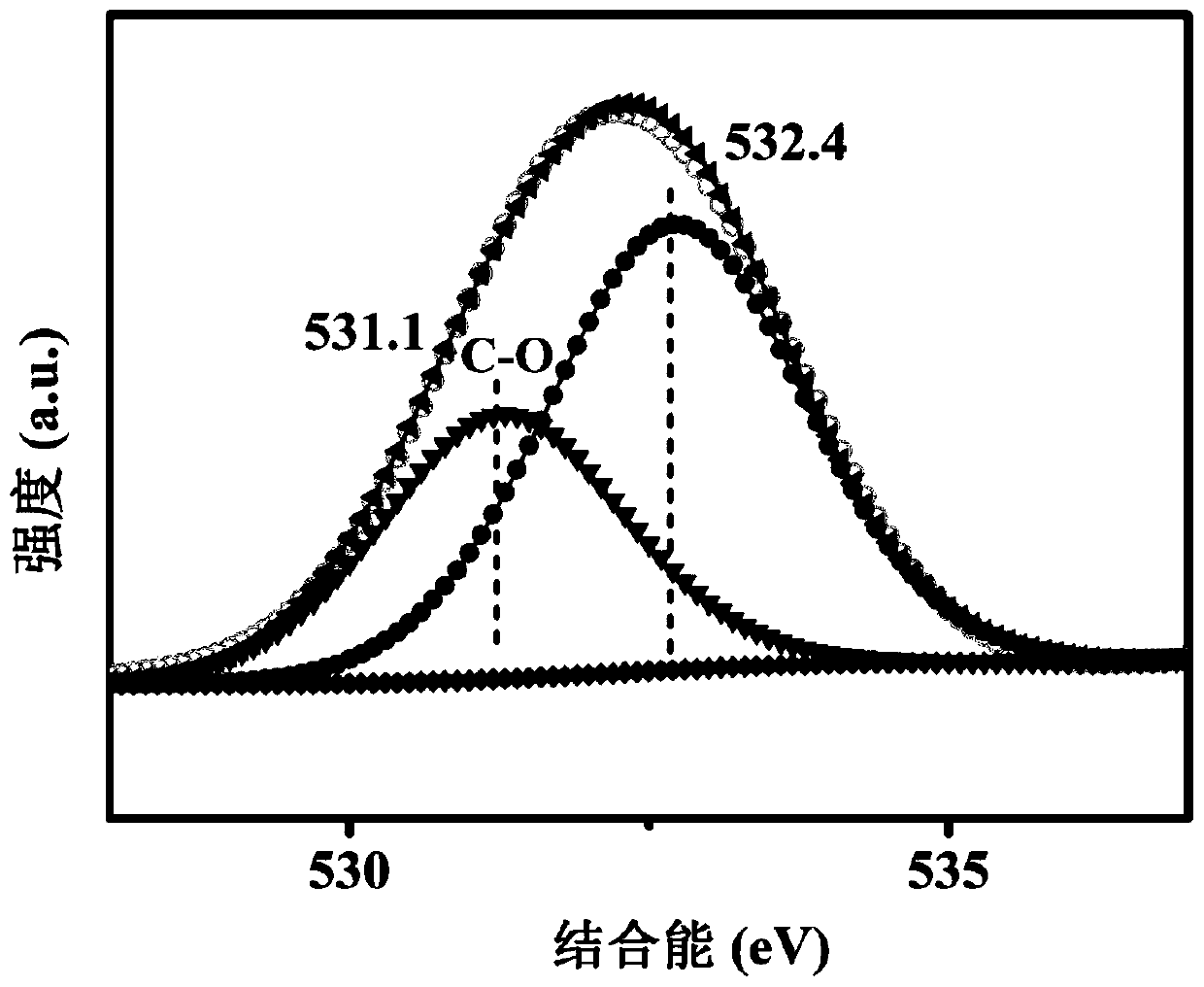

[0037] The g-C that embodiment 1 obtains powder TEM and X-ray photoelectron spectroscopy (XPS) photo, r...

Embodiment 2

[0039] Step 1, according to the mass ratio of melamine and deionized water is 1:5, the volume ratio of ethanol and deionized water is 1:50, add melamine, ethanol, deionized water to the clean polytetrafluoroethylene liner and mix, Stir evenly; cover the above polytetrafluoroethylene liner with a lid, put it into the corresponding stainless steel jacket, tighten it, put it in an oven, and keep it warm at 200 ° C for 6 hours; after cooling with the furnace, the obtained solid-liquid mixture is deionized Water and absolute ethanol were washed by centrifugation for 6 times, and then dried in an oven at 80°C for 12 hours to obtain the modified melamine precursor.

[0040] Step 2: Put the precursor obtained in Step 1 into an alumina crucible and cover it; heat preservation at 600°C for 1 hour, and calcining at a heating rate of 1°C / min to obtain porous carbon nitride nanosheets.

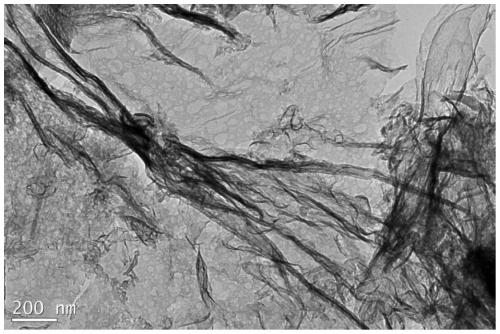

[0041] The g-C that embodiment 2 obtains 3 N 4 Powder TEM photographs, such as image 3 As shown, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com