Polishing machine

A polishing machine and polishing mechanism technology, applied in the field of polishing machines, can solve the problems of inability to wash tile walls, inability to polish and refurbish brick walls, and inability to spray dust to reduce dust, etc., achieving convenient polishing, reducing spray dead angle, increasing Effect of spray area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

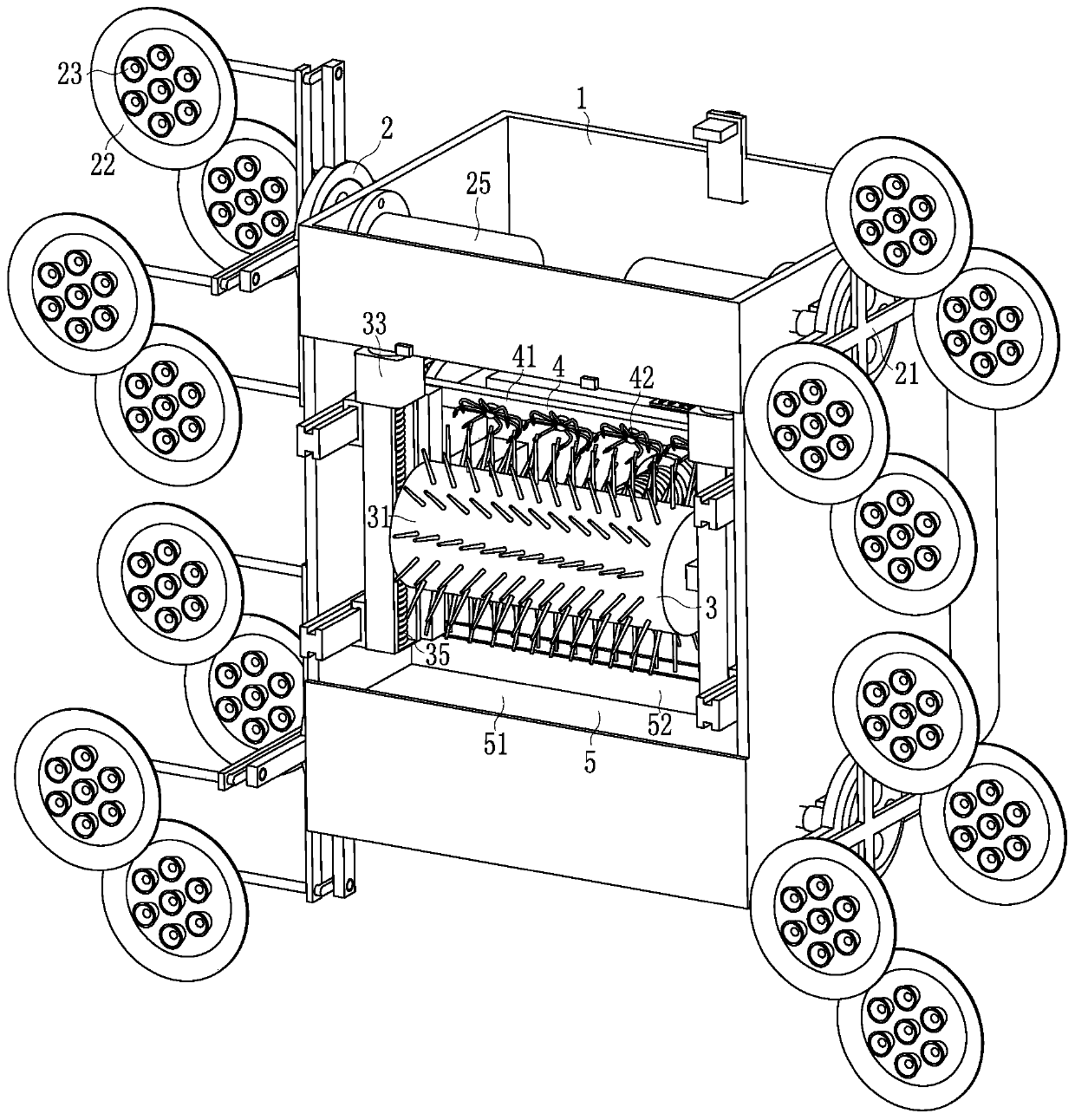

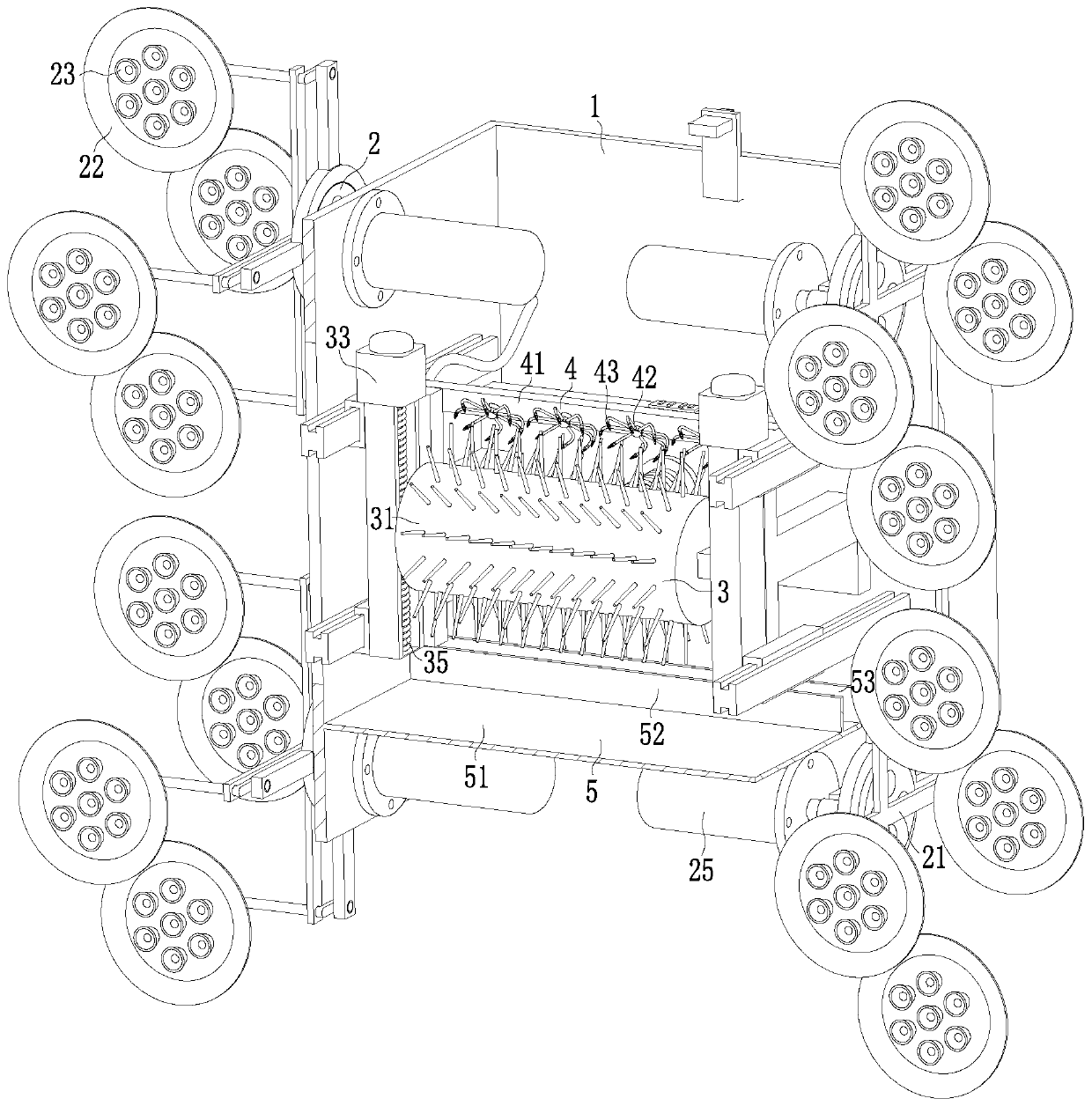

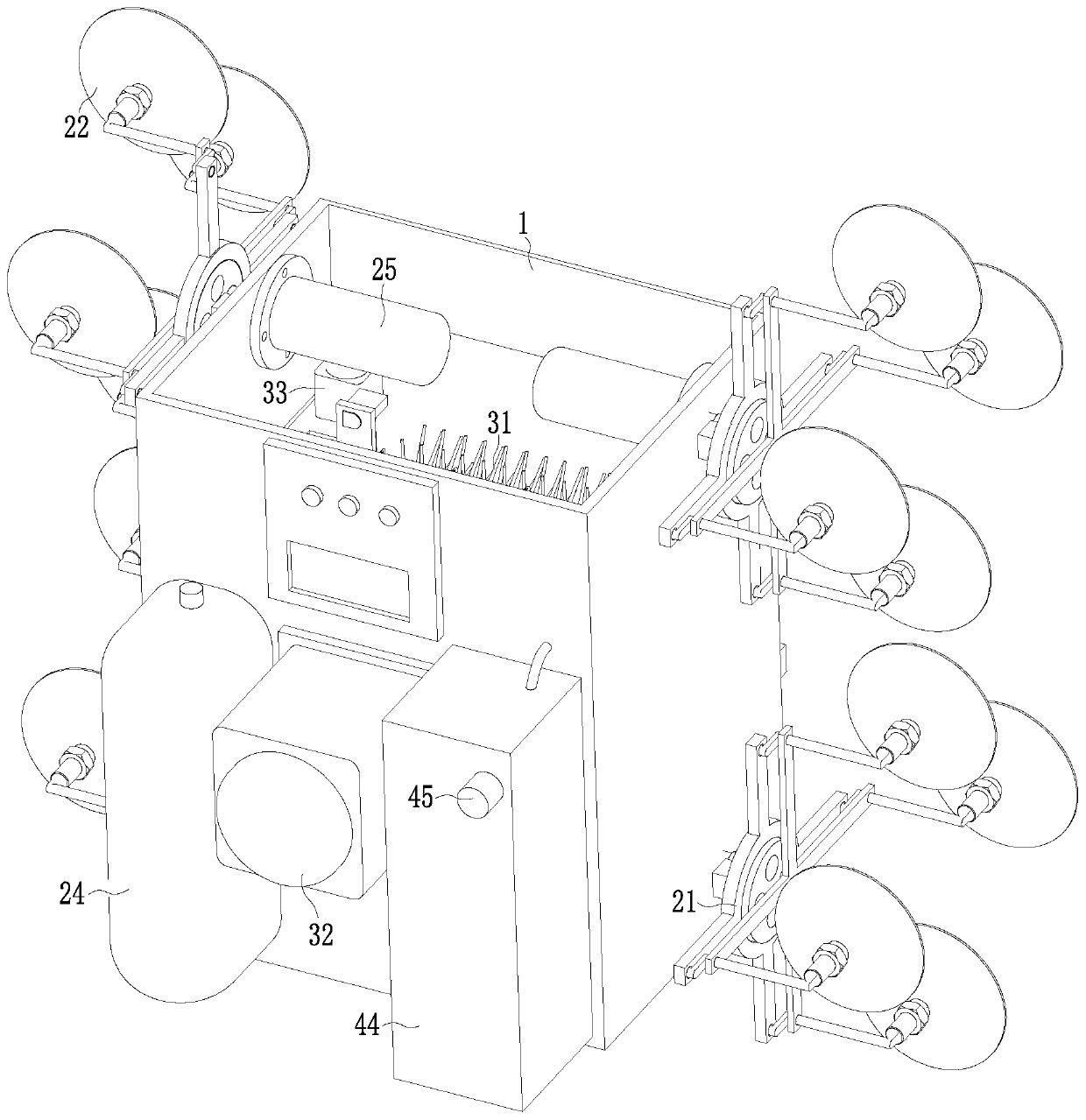

[0026] use Figure 1 to Figure 7 A polishing machine of the present invention is described as follows, the front, back, left and right directions involved in the present invention are figure 1 as the benchmark.

[0027] like Figure 1 to Figure 7 As shown, a polishing machine according to the present invention includes a casing 1, a wall-climbing mechanism 2, a polishing mechanism 3, a flushing device 4, a filtering device 5 and a controller; the wall-climbing mechanism 2 is installed on the On both sides, the number of wall-climbing mechanisms 2 is at least four, and the wall-climbing mechanism 2 is used to adsorb on the tile wall and drive the shell 1 to crawl along the tile wall; the polishing mechanism 3 is installed in the inner center of the shell 1 , the polishing mechanism 3 is used for scrubbing the stains on the surface of the ceramic tile wall surface and polishing the dull ceramic tile surface and the rough ceramic tile surface; the flushing device 4 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com