A method for efficiently preparing ternary diffusion couples

A diffusion couple, high-efficiency technology, applied in the field of thermodynamics research, can solve problems such as holes in the node position, and achieve the effect of not easy to generate voids, tight bonding, and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

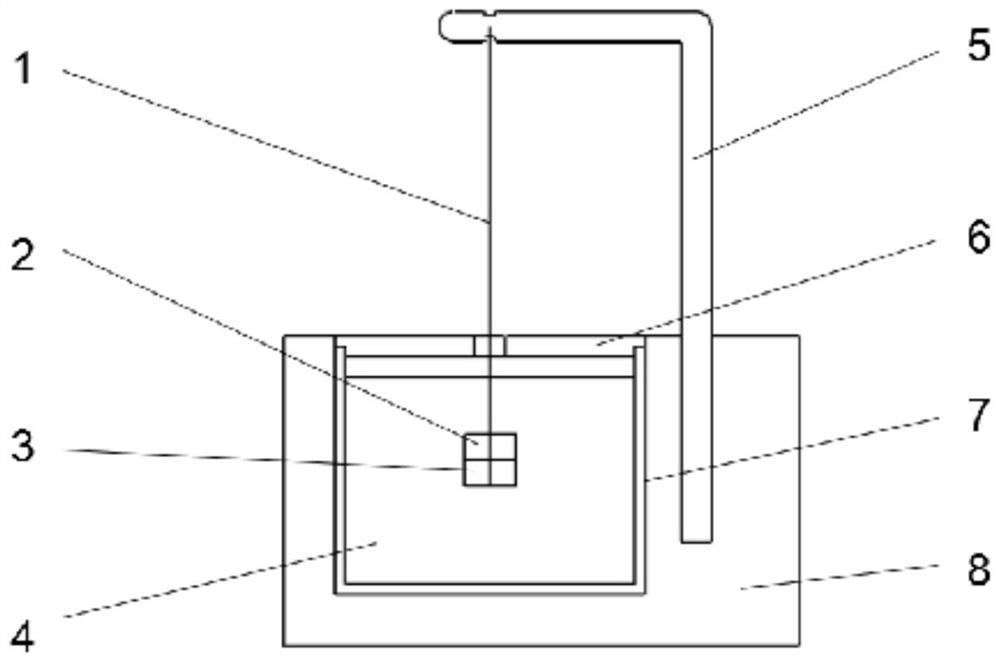

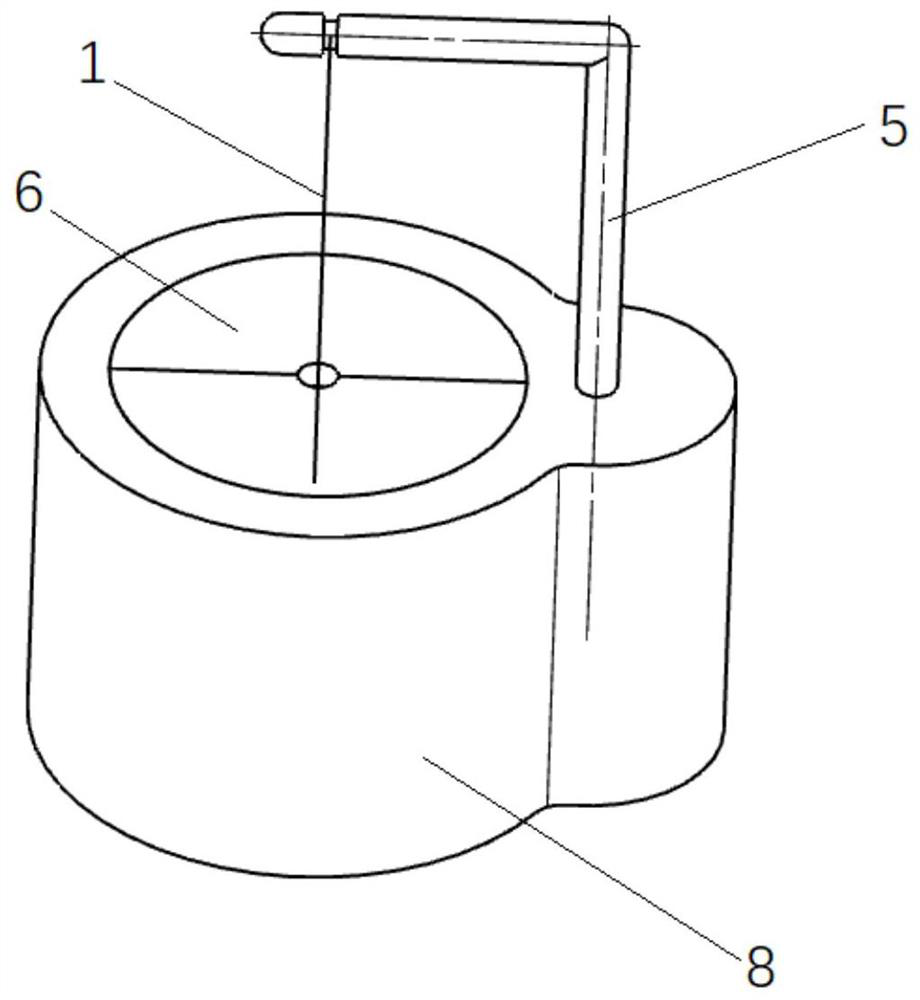

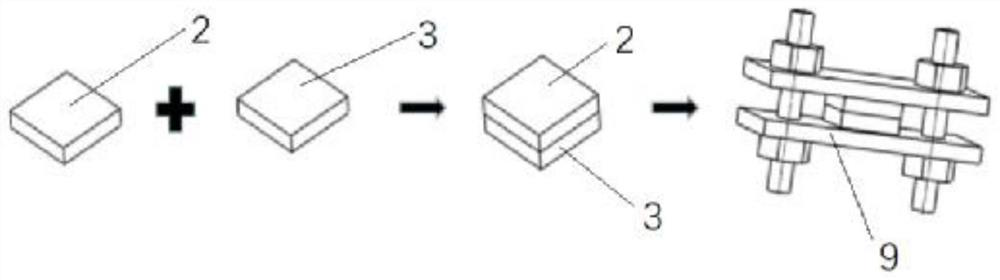

[0029] Example 1: First, the electrolytic copper block with a purity of 99.95% and the silver block with a purity of 99.9% are cut into small pieces of 5 × 10 × 10 mm by wire cutting, and the copper block and silver block are cut by the method of grinding metallography. The surface to be diffused of the block is ground and polished to a mirror surface, cleaned with alcohol, and then fixed with a clamp 9, such as image 3 As shown, the quartz tube is put into vacuum and sealed, and after heat treatment, a "Japanese-shaped" binary diffusion couple is made; after the quartz tube is cooled, the binary diffusion couple is taken out, and the four surfaces to be diffused are ground and polished Polish to the mirror surface, clean it with alcohol, bind it with molybdenum wire, and fill the mold with block pure aluminum so that the height of the block pure aluminum is 3cm higher than the highest point of the binary diffusion couple, and cover the crucible cover, and then put it into a ...

Embodiment 2

[0030]Embodiment 2: Firstly, a nickel block with a purity of 99.9% and a titanium block with a purity of 99.9% are cut into small pieces of 5×10×10 mm by a wire cutting method, and the surface to be diffused of the nickel block and the titanium block is ground by a metallographic grinding method Flatten and polish to the mirror surface, clean it with alcohol, then fix it with a fixture, put it into a quartz tube and vacuumize it, seal it, and make a "Japanese-shaped" binary diffusion couple after heat treatment; after the quartz tube cools down, take out the binary diffusion couple Even, the four surfaces to be diffused are ground and polished to the mirror surface, cleaned with alcohol, bound with molybdenum wire, and filled with block pure copper in the mold, so that the height of the block pure copper can reach the highest At the position of 3cm from the highest point of the binary diffusion couple, cover the crucible lid, and then put it into a box-type muffle furnace. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com