Denitration catalyst as well as preparation method and application thereof

A denitrification catalyst and compound technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., to achieve the effect of non-toxic, harmless, simple operation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

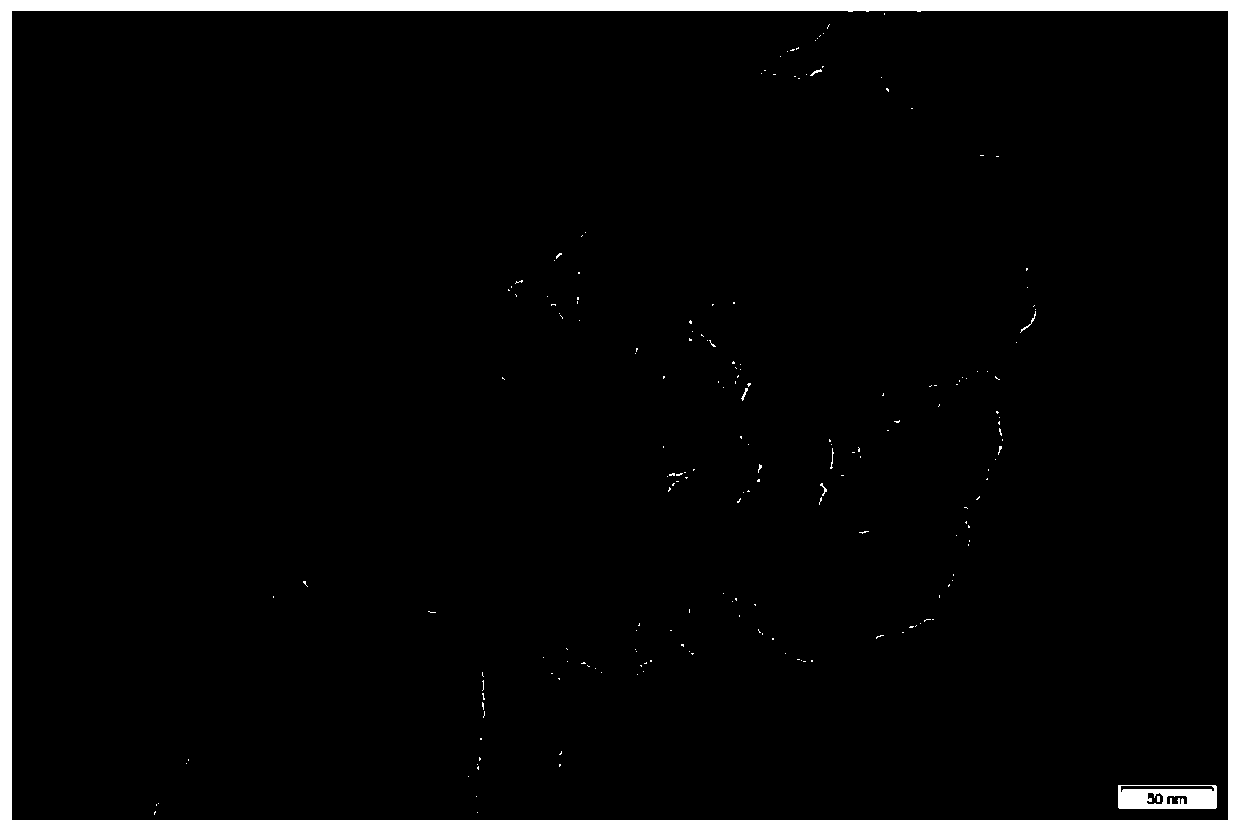

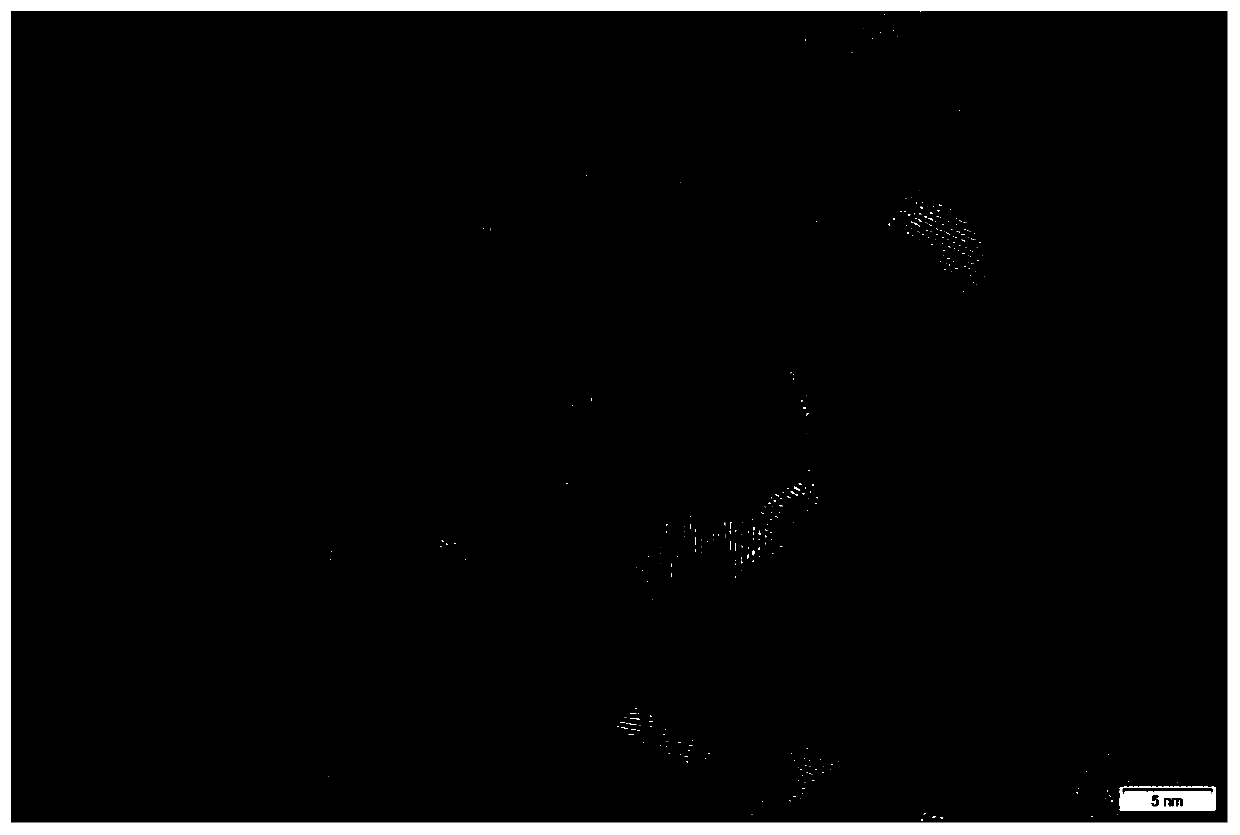

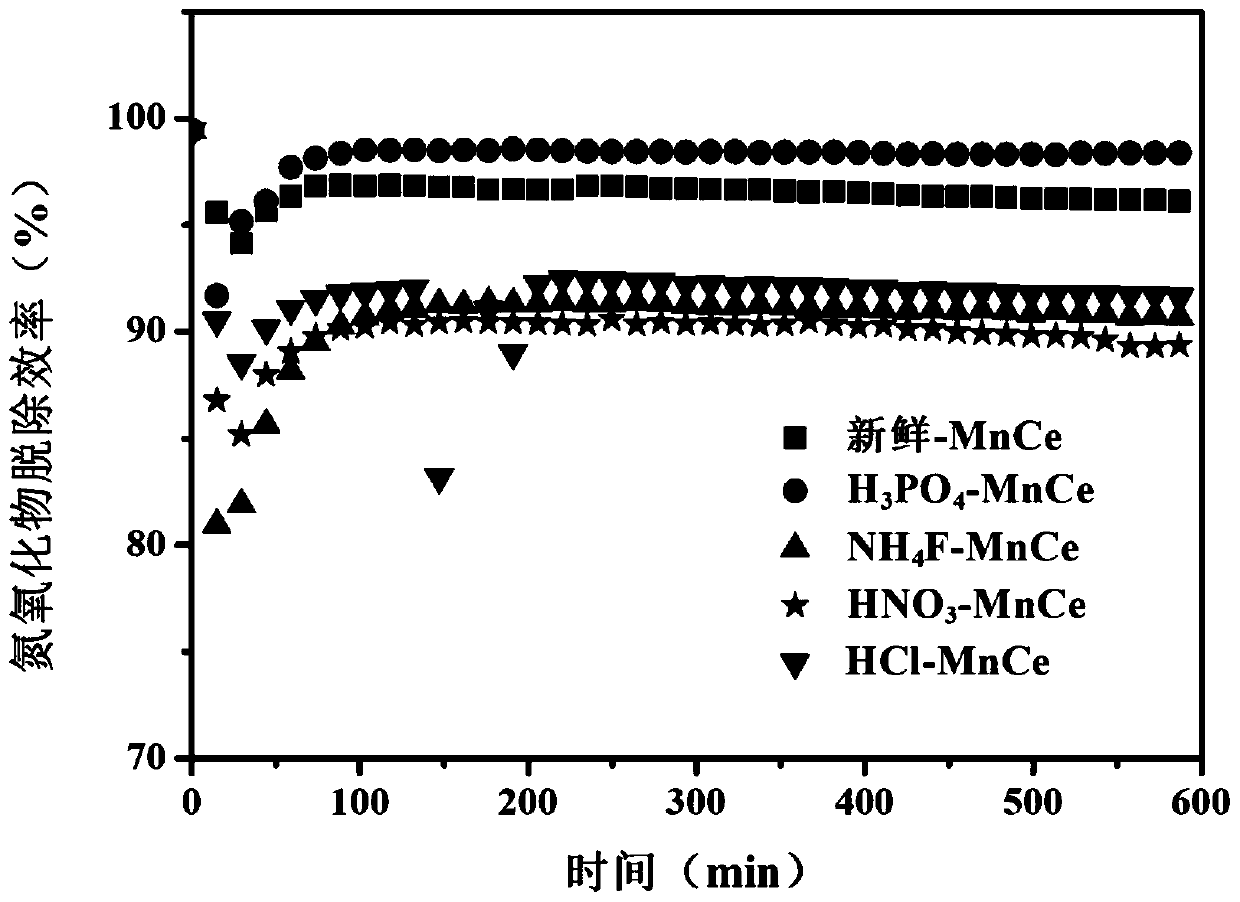

[0064] The first embodiment of the present invention provides a denitration catalyst comprising CeO doped with a Mn compound 2 ,in,

[0065] The surface of the denitration catalyst has active ions, and the active ions include inorganic acid ions. Preferably, the electronegativity of all elements of the inorganic acid ions may be greater than 2, for example, above 2.1.

[0066] Further, the electronegativity of all elements except the hydrogen element of the inorganic acid radical ion can preferably be greater than 2.1, more preferably the electronegativity is above 2.2, further preferably the electronegativity is above 2.3, and even more preferably the electronegativity is above 2.3. 2.4 or higher, more preferably an electronegativity of 2.5 or higher, still more preferably an electronegativity of 2.6 or higher. Although the mechanism is not completely clear, when the electronegativity of the inorganic acid radical ion of the present invention is above 2.6 for all elements ex...

no. 2 approach

[0085] In the second embodiment of the present invention, a preparation method of the denitration catalyst of the first embodiment is provided, the preparation method includes the step of modification treatment after preparation by co-precipitation method.

[0086]

[0087] The co-precipitation method refers to the solution containing two or more cations, which exist in the solution in a homogeneous phase, adding a precipitating agent, and after precipitation reaction, a uniform precipitation of various components can be obtained. An important method for the composite oxide ultrafine powder of two or more metal elements.

[0088] The present invention uses the co-precipitation method, and the powder material can be directly obtained through chemical reaction in the solution. Specifically, in the process of co-precipitation, the process conditions that can be controlled include: chemical ratio, solution concentration, solution temperature, type and quantity of dispersant, mix...

no. 3 approach

[0125] The third embodiment of the present invention provides a denitrification catalyst prepared according to the first embodiment of the present invention or the preparation method of the second embodiment of the present invention to catalytically remove nitrogen oxides and chlorine volatilization in flue gas Uses of sexual organisms.

[0126] When used for removing nitrogen oxides, it may be a denitration catalyst composition. The denitration catalyst composition may include other various denitration catalysts known in the art. In a preferred embodiment of the present invention, the denitration catalyst composition includes at least 60% by mass of the denitration catalyst described in the present invention, preferably 80% by mass or more, more preferably 90% by mass or more, based on the weight of the denitration catalyst composition Total Mass Meter.

[0127] The denitration catalyst of the present invention can catalyze the removal of nitrogen oxides and chlorine-contai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com