Bi-linear CCD-based dilutor spatial vision positioning deviation correction method

A technology of visual positioning and deviation correction, which is applied in the direction of instruments, photo interpretation, measuring devices, etc. It can solve the problems of unpredictable global distribution of sample bottles, ineffective improvement of liquid dispensing efficiency, and affecting positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

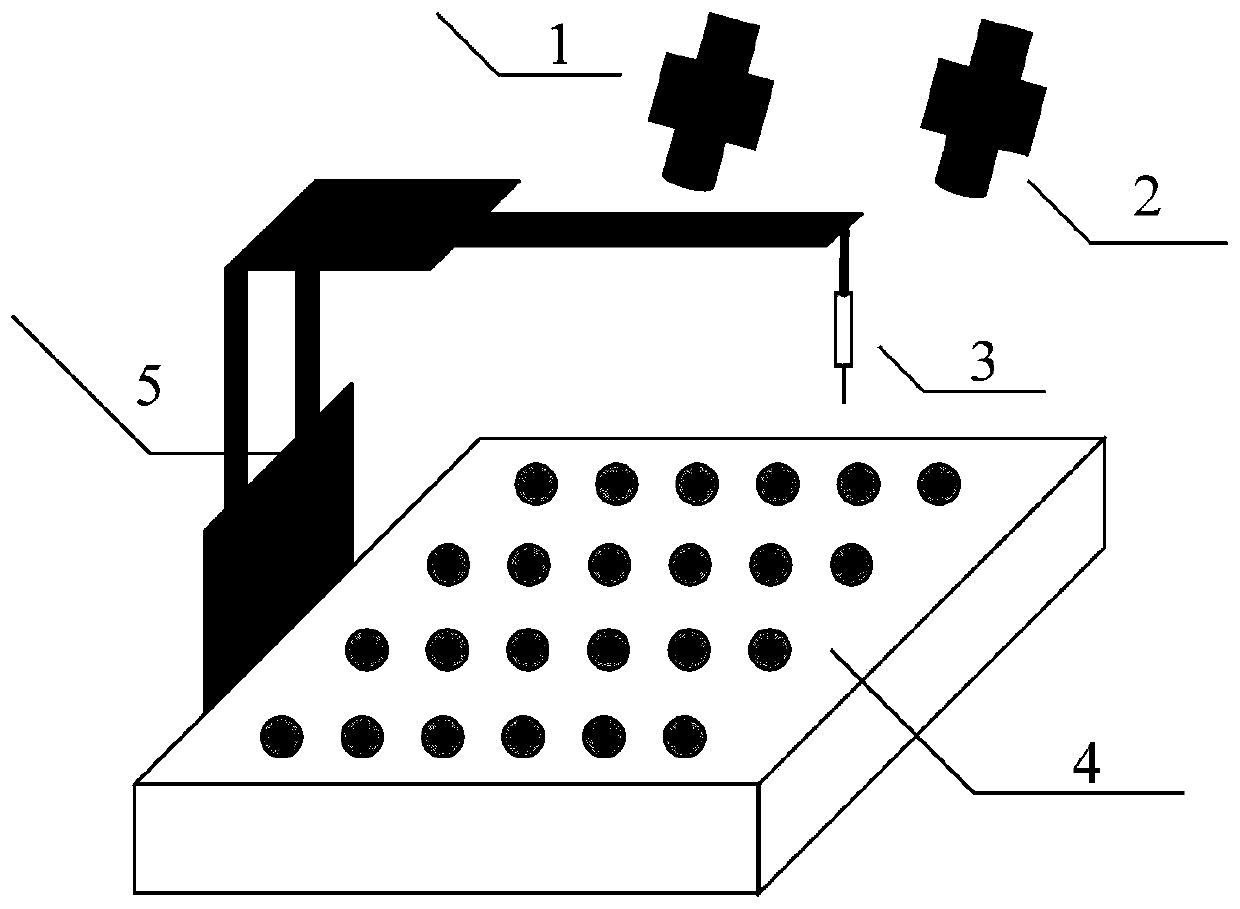

[0066] according to figure 1 As shown in the flow chart, the present invention provides a method for correcting the spatial visual positioning deviation of a diluter based on a dual linear array CCD, comprising the following steps:

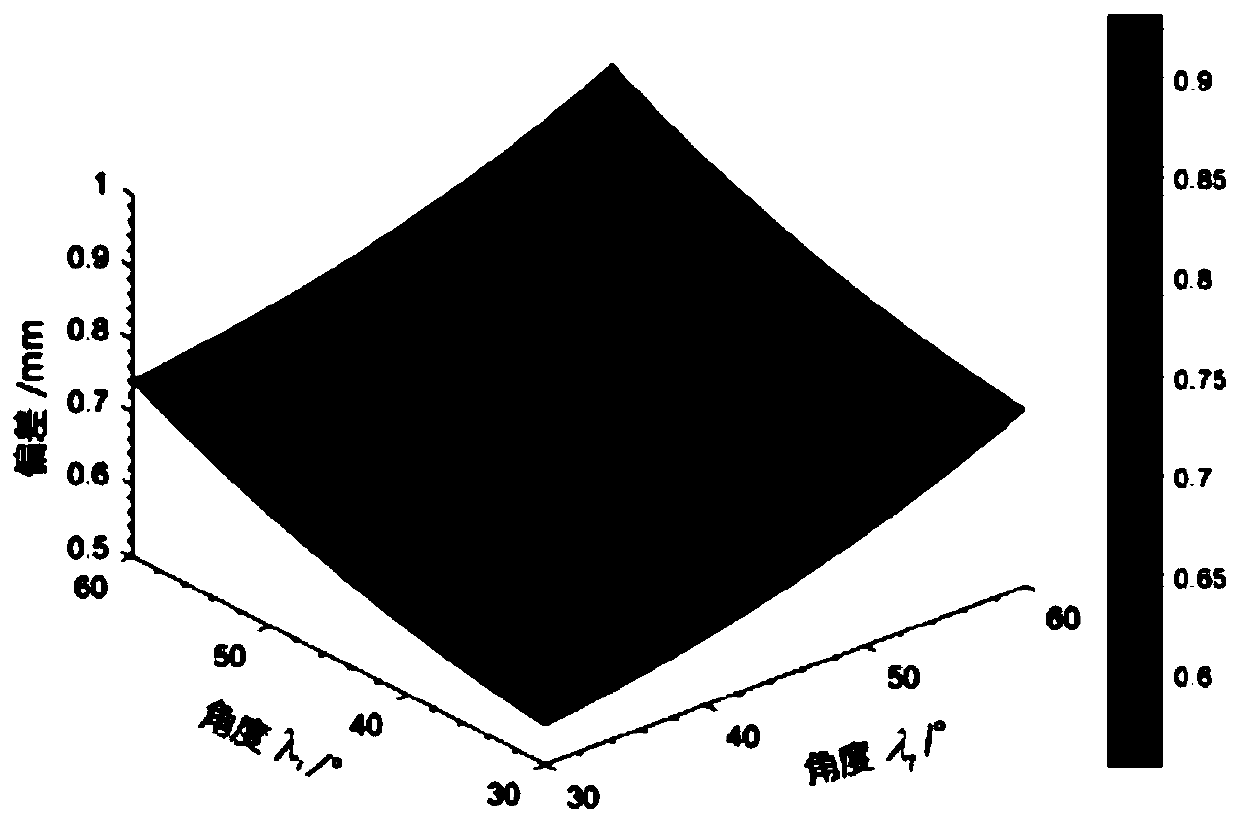

[0067] Step 1: Determine the angle λ between the optical axis of the dual linear array CCD and the line connecting the optical center l and lambda r Influence on the visual positioning accuracy of the system, set the space point p, p(x, y, z), and determine the angle λ between the optical axis and the optical center of the dual linear array CCD l and lambda r Positioning deviation caused by changes, dual linear array CCD includes linear array CCD1 and linear array CCD2;

[0068] Step 2: Determine the relationship between the angle between the dual linear array CCDs and the positioning deviation, construct a vector synthesis function, and perform partial derivatives on the influence factors in the constructed vector synthesis function to obtain ...

specific Embodiment 2

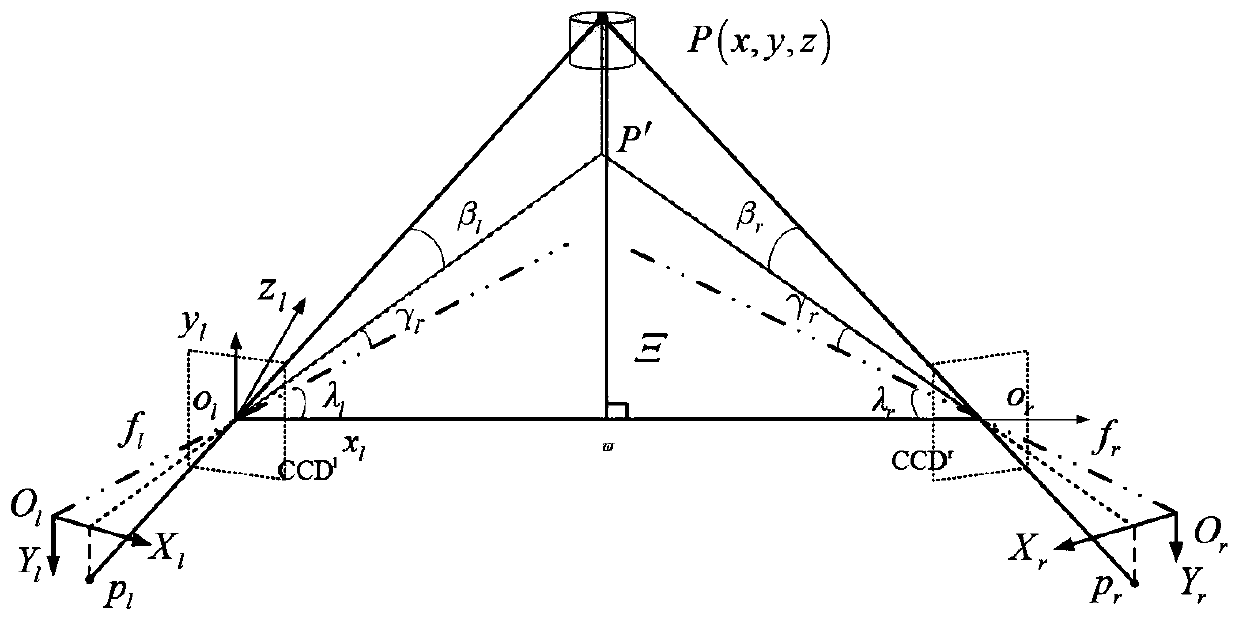

[0100] Step 1: The spatial distribution and imaging model of two linear array CCDs in stereo vision positioning are as follows: figure 2 Shown, O l -X l Y l with O r -X r Y r are the scanning imaging surface coordinate system of linear array CCD1 and linear array CCD2 respectively; o l and o r is the optical center of the linear array CCD, and the distance between the optical centers can be regarded as the physical distance of the linear array CCD; f l ,f r are the focal lengths of the two linear array CCDs respectively; the vertical distance between the sample bottle and the two linear array CCDs is Ξ; according to the principle of small hole imaging, the center point P (x, y, z) of the sample bottle cap is along the optical axis O l o l and O r o r The projection coordinates on the image plane of linear array CCD1 and linear array CCD2 are respectively p l (U l ,V l ), p r (U r ,V r ). Make the system measurement coordinate system coincide with the left li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com