Pressure sensitive composite material used in flexible sensor and preparation method thereof

A pressure-sensitive composite material and flexible sensor technology, applied in the field of sensors, can solve the problems affecting the electrical conductivity and piezoresistive properties of the pressure-sensitive composite material, poor dispersion, etc., and achieve excellent processability, improved mechanical properties, and excellent aging resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

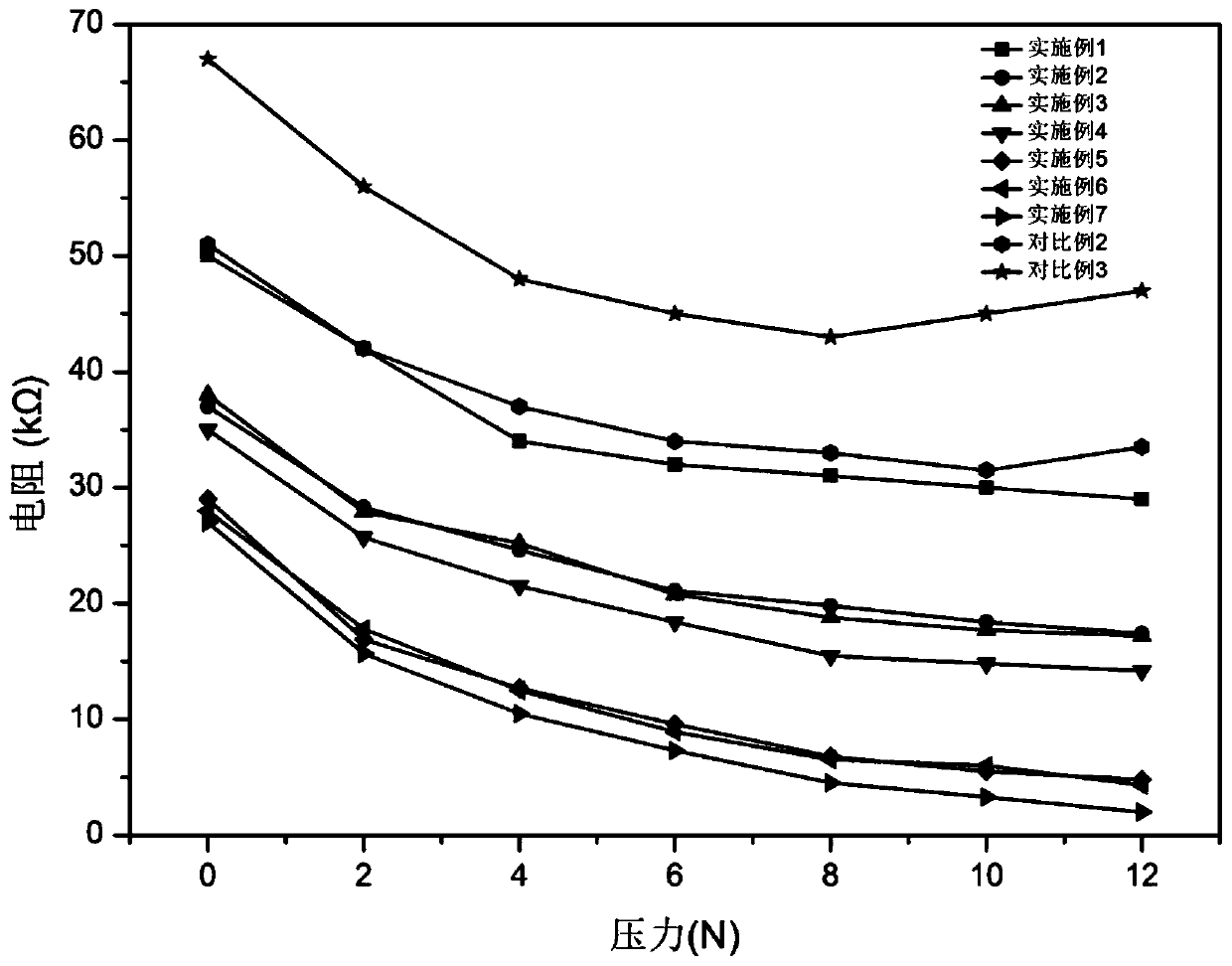

Embodiment 1

[0047] 20g Ketjen carbon black ECP600JD, 5g carbon nanotubes, 20g nano-SiO 2 and 40g of 2% silane coupling agent Si-69, added to 115g of naphtha, stirred and ultrasonically dispersed for 30min to form a dispersion. Add 450g room temperature vulcanized silicone rubber Dow Corning 184 to the dispersion, stir magnetically at room temperature for 3 hours to form a viscous mixture, place the mixture in a vacuum drying oven at 40°C and dry for 20 minutes to remove air bubbles and incompletely volatilized naphtha, That is, an uncured pressure-sensitive composite material is obtained.

Embodiment 2

[0049] 20g Ketjen carbon black ECP600JD, 5g carbon nanotubes, 5g nano-SiO 2 and 10g of 2% silane coupling agent Si-69, added to 85g of naphtha, stirred and ultrasonically dispersed for 30min to form a dispersion. Add 350g room temperature vulcanized silicone rubber Dow Corning 184 to the dispersion, stir magnetically at room temperature for 3 hours to form a viscous mixture, place the mixture in a vacuum drying oven at 40°C and dry for 20 minutes to remove air bubbles and incompletely volatilized naphtha, That is, an uncured pressure-sensitive composite material is obtained.

Embodiment 3

[0051] 75g Ketjen carbon black ECP600JD, 25g carbon nanotubes, 20g nano-SiO 2 And 40g of 2% silane coupling agent Si-69, add 25g of n-hexane, 65g of naphtha and 25g of absolute ethanol mixed solution, after stirring, ultrasonically disperse for 60min to form a dispersion. Add 450g of room temperature vulcanized silicone rubber Dow Corning 184 to the dispersion, stir magnetically at room temperature for 8 hours to form a viscous mixture, place the mixture in a vacuum drying oven at 100°C for 30 minutes, and remove air bubbles and incompletely volatilized solvents. Uncured pressure-sensitive composites were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com