Water dispersed isocyanate curing agent with delustring effect, and preparation method thereof

A technology of isocyanate and polyisocyanate, which is applied in the field of water-dispersed isocyanate curing agent and preparation, can solve the problems of water and chemical resistance decline, medium gloss effect, and deterioration of paint film mechanical properties, and achieve simple preparation and excellent matting effect , Excellent water and chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

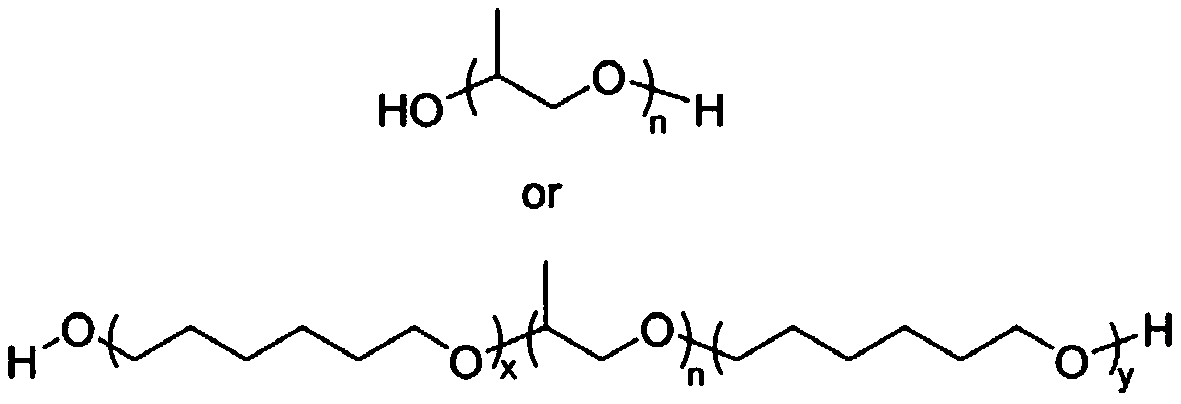

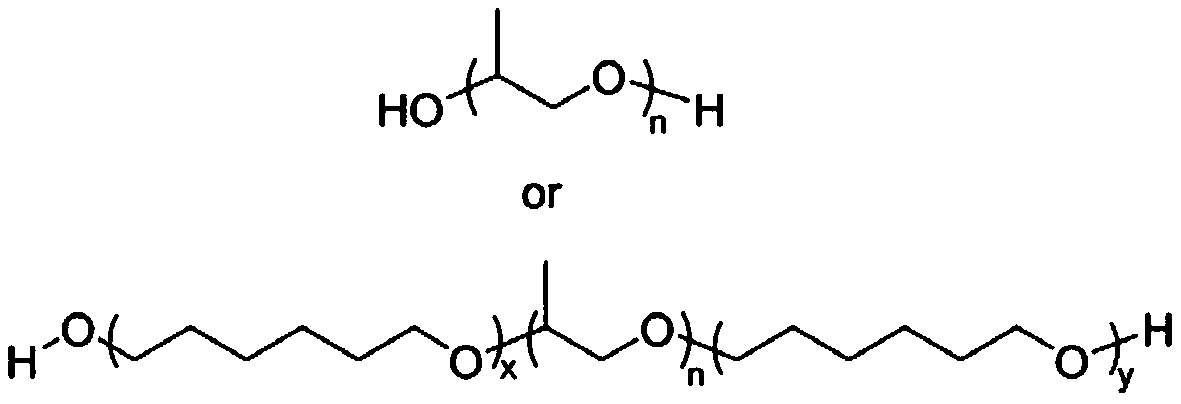

Method used

Image

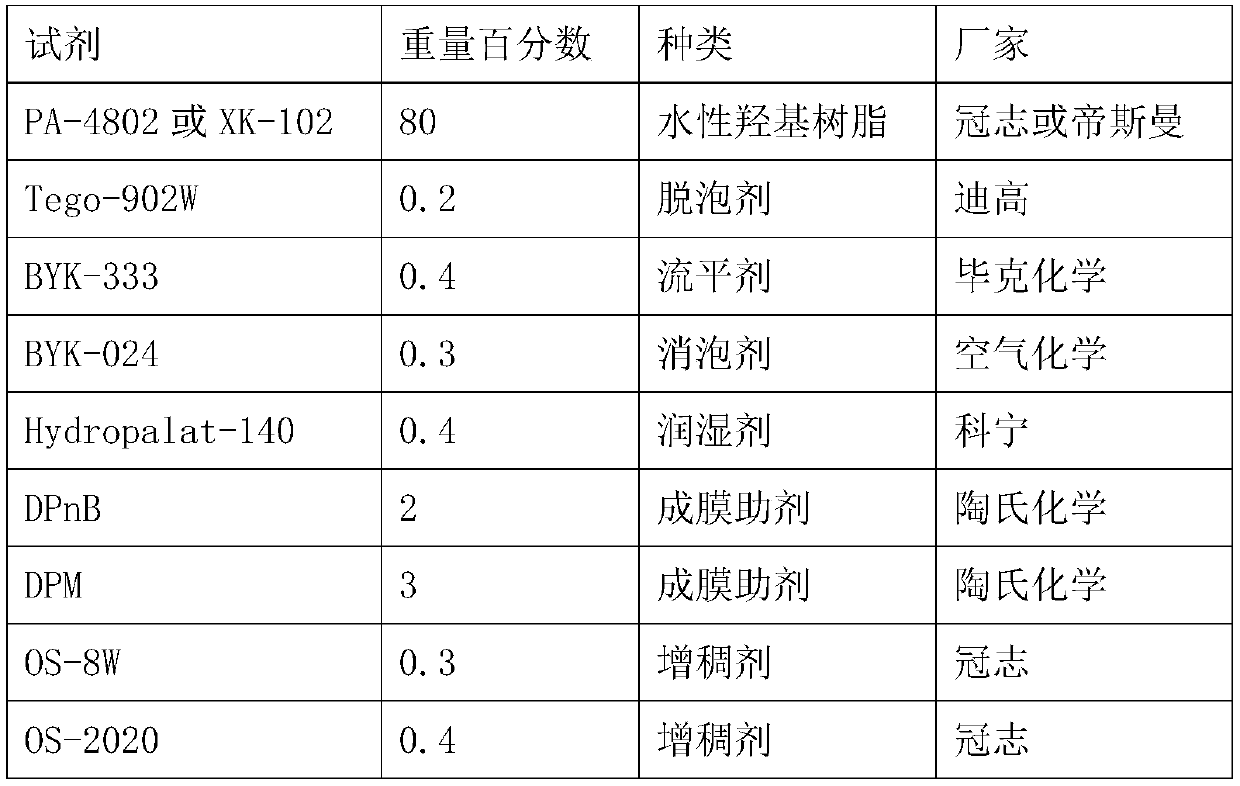

Examples

Embodiment 1

[0023] Mix 110.0 parts by mass of polyethylene glycol monomethyl ether (500 molecular weight, Haian Petrochemical, Jiangsu Province) and 50 parts by mass of polypropylene glycol N210 (1000 molecular weight, Dow Chemical), heat to 100-110°C and vacuumize for 2 hours; cool to 60 ℃, add 840.0 parts by mass of Desmodur N 3300 (Covestro solvent-free HDI trimer, NCO content 21.8±0.3%, NCO average functionality 3.5), raise the temperature to 100 ℃, and continue the reaction at this temperature for 4h. After cooling to room temperature, the obtained 100% solid-containing hydrophilic modified polyisocyanate was a near colorless transparent viscous liquid with a measured NCO value of 17.0% and a viscosity (25° C.) of 3800 cps.

Embodiment 2

[0025] Synthesis of modified polypropylene glycol caprolactone: 100.0 parts by mass of polypropylene glycol N210 (1000 molecular weight, Dow Chemical) and 80.0 parts by mass of ε-caprolactone, 0.2 parts by mass of stannous octoate are put into the reaction kettle, and nitrogen protection is carried out. , heated to 130°C, reacted for 24 hours, and cooled to room temperature to obtain a waxy white solid modified polypropylene glycol caprolactone with a theoretical molecular weight of 1800.

[0026] Heat 125.0 parts by mass of polyethylene glycol monomethyl ether (750 molecular weight, Haian Petrochemical, Jiangsu Province) and 40.0 parts by mass of the modified polypropylene glycol caprolactone (1800 molecular weight) synthesized above to 100-110° C. for 2 hours. Cool down to 60 ° C, add Desmodur N 3900 (Covestro solvent-free HDI trimer, NCO content is 23.5 ± 0.3%, NCO average functionality is 3.2) 840.0 parts by mass, after the addition, the temperature is raised to 100 ° C, an...

Embodiment 3

[0028] Mix 110.0 parts by mass of polyethylene glycol monomethyl ether (500 molecular weight, Jiangsu Haian Petrochemical) and 10 parts by mass of polypropylene glycol N210 (1000 molecular weight, Dow Chemical), heat to 100-110°C and vacuumize for 2 hours; cool to 60 ℃, add DesmodurZ 4470MPA / X (Covestro IPDI trimer, 70% solid content, NCO content is 11.9 ± 0.3%, NCO average functionality is 3.5) 840.0 mass parts, propylene glycol methyl ether acetate 50.0 mass parts, heating to 110°C, and the reaction was continued at this temperature for 4h. After cooling to room temperature, the obtained 70% solid-containing hydrophilic modified polyisocyanate is a nearly colorless transparent viscous liquid with a measured NCO value of 9.40% and a viscosity (25° C.) of 700 cps.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com