a cu 2 Preparation method of o/zno composite photocatalyst

A catalyst and composite light technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low utilization of sunlight, reduced photocatalytic activity, Weak absorption and other problems, to achieve the effect of good photocatalytic effect, high recycling rate and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

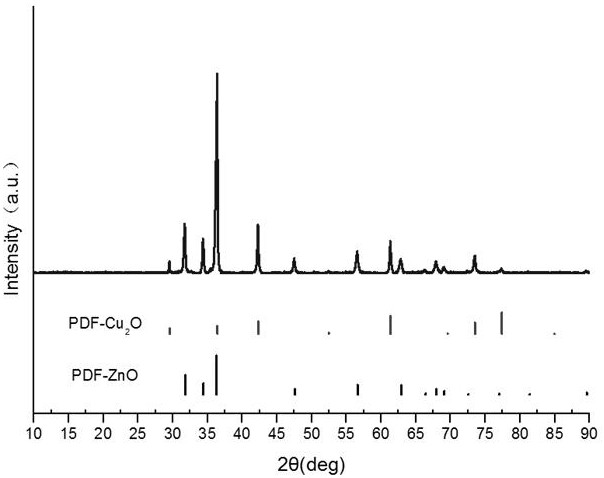

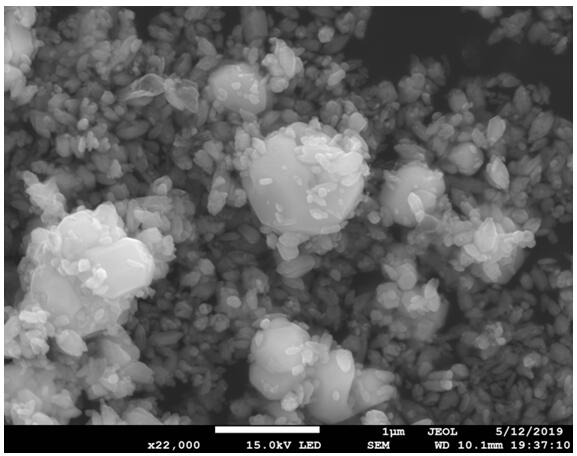

[0031] Embodiment 1: a kind of Cu 2 The preparation method of O / ZnO composite photocatalyst, concrete steps are as follows:

[0032] (1) Dissolve copper salt and zinc salt in water to obtain a mixed salt solution; the copper salt is Cu(NO 3 ) 2 , the zinc salt is Zn(NO 3 ) 2 , the molar ratio of copper in the copper salt and zinc in the zinc salt is 1:1, and the concentration of zinc ions in the mixed salt solution is 0.10mol / L;

[0033] (2) Under stirring conditions, drop the precipitant solution (alkaline solution) into the mixed salt solution in step (1) to react until the pH value is 7~7.5 to obtain a reaction system. The reaction system is ultrasonically treated for 15 minutes, and stirred for 2 hours. ; Filter to obtain the copper-zinc hydroxide solid; Wherein the precipitant solution (alkaline solution) is a sodium hydroxide solution, and the concentration of the sodium hydroxide solution is 0.5120mol / L; the titration rate of the precipitant solution (alkaline solut...

Embodiment 2

[0038] Embodiment 2: a kind of Cu 2 The preparation method of O / ZnO composite photocatalyst, concrete steps are as follows:

[0039] (1) Dissolve copper salt and zinc salt in water to obtain a mixed salt solution; the copper salt is Cu(NO 3 ) 2 , the zinc salt is Zn(NO 3 ) 2, the molar ratio of copper in the copper salt and zinc in the zinc salt is 0.625:1, and the concentration of zinc ions in the mixed salt solution is 0.101mol / L;

[0040] (2) Under stirring conditions, add the precipitant solution (alkaline solution) drop by drop into the mixed salt solution in step (1) to react until the pH value is 7~7.5 to obtain a reaction system, and the reaction system is ultrasonically treated for 30 minutes, and then stirred 1.5 h; filter to obtain copper-zinc hydroxide precipitation; wherein the precipitant solution (alkaline solution) is ammonia water, the concentration of ammonia water is 0.5075mol / L; the titration rate of the precipitant solution (alkaline solution) is 2-4 d...

Embodiment 3

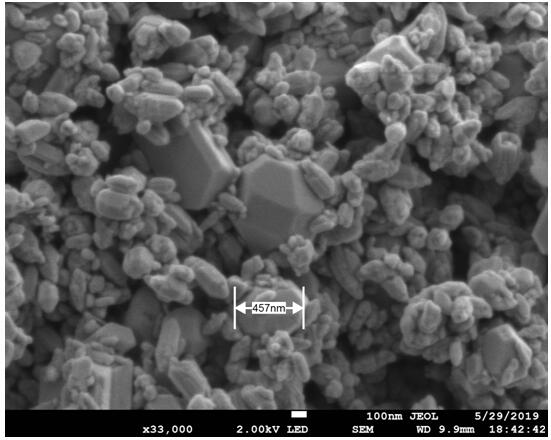

[0045] Embodiment 3: a kind of Cu 2 The preparation method of O / ZnO composite photocatalyst, concrete steps are as follows:

[0046] (1) Dissolve copper salt and zinc salt in water to obtain a mixed salt solution; the copper salt is Cu(CH 3 COO) 2 , the zinc salt is Zn(CH 3 COO) 2 , the mol ratio of copper in the copper salt and zinc in the zinc salt is 0.19047:1, and the concentration of zinc ions in the mixed salt solution is 0.1023 mol / L;

[0047] (2) Under stirring conditions, drop the precipitant solution (alkaline solution) dropwise into the mixed salt solution in step (1) to react until the pH value is 7~7.5 to obtain a reaction system. The reaction system is ultrasonically treated for 30 minutes, and stirred for 1.5 minutes. h; filter to obtain the copper-zinc hydroxide solid, wherein the precipitant solution (alkaline solution) is a sodium hydroxide solution, and the concentration of the sodium hydroxide solution is 0.5021mol / L; the titration rate of the precipita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com