Barium sulfate suspension system with uniform dispersion and low viscosity, and preparation method and application thereof

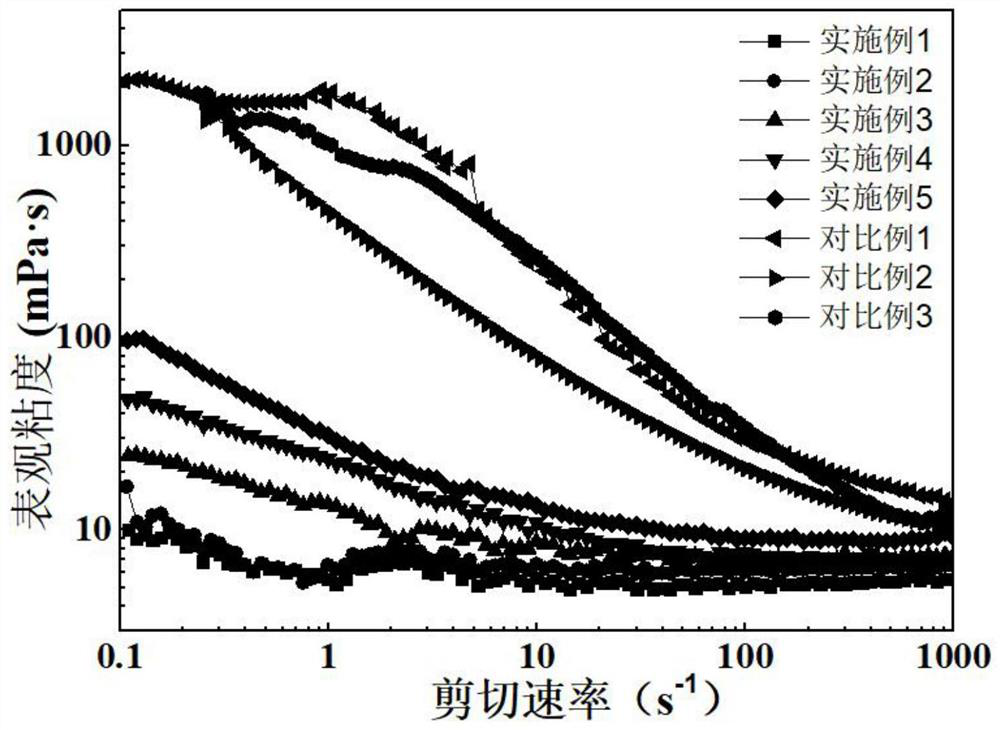

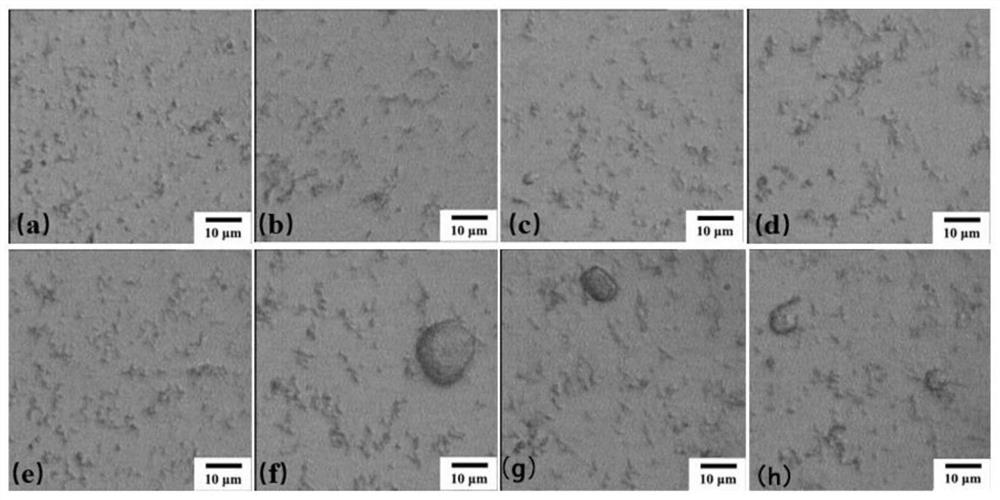

A uniformly dispersed, barium sulfate technology, applied in chemical instruments and methods, drilling compositions, coatings, etc., can solve the problems of particle agglomeration, uneven dispersion, inability to stabilize the viscosity of the dispersion system, and achieve good rheological properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a method for preparing the uniformly dispersed and low-viscosity barium sulfate suspension system described in the above technical solution, comprising: adding barium sulfate particles after mixing the fatty alcohol polyoxyethylene ether carboxylic acid and the oil phase, and then ultrasonicating to obtain sulfuric acid Barium Suspension System.

[0029] The invention mixes the fatty alcohol polyoxyethylene ether carboxylic acid and the oil phase to obtain the oil solution.

[0030] In the present invention, the mixing of the fatty alcohol polyoxyethylene ether carboxylic acid and the oil phase is preferably carried out under stirring conditions; the stirring is preferably magnetic stirring, and the stirring speed is preferably 400-1000r / min, more preferably 500~800r / min, most preferably 600r / min; the time of the stirring is preferably 5~25min, more preferably 10~20min, most preferably 15min; the temperature of the stirring is prefera...

Embodiment 1

[0038]In terms of parts by mass, the barium sulfate suspension system consists of: 0.01 part of fatty alcohol polyoxyethylene ether carboxylic acid (alkyl chain carbon number 3, oxirane number 3), 5 parts of barium sulfate particles (barium sulfate particle density 4.5g / cm, particle size 0.5μm), gas-to-oil (185V) 94.99 parts.

[0039] The preparation method of the barium sulfate suspension system in the present embodiment is: add 0.01 part of fatty alcohol polyoxyethylene ether carboxylic acid (alkyl chain carbon number 3, oxirane number 3) to 94.99 parts of gas oil, 25 ℃, 400r / min magnetic stirring for 5min, add 5 parts of barium sulfate particles, 25°C, 400r / min magnetic stirring for 5min, then ultrasonic, ultrasonic power 400W, ultrasonic time is 20 cycles (ultrasonic 5s, interval 5s).

Embodiment 2

[0041] In terms of parts by mass, the barium sulfate suspension system consists of: 0.1 part of fatty alcohol polyoxyethylene ether carboxylic acid (alkyl chain carbon number 7, ethylene oxide number 7), 15 parts of barium sulfate particles (barium sulfate particle density 4.5g / cm, particle size 0.5μm), gas-to-oil (185V) 84.9 parts.

[0042] The preparation method of the barium sulfate suspension system in the present embodiment is: add 0.1 part of fatty alcohol polyoxyethylene ether carboxylic acid (alkyl chain carbon number 7, oxirane number 7) to 84.9 parts of gas oil, 25 ℃, 500r / min magnetic stirring for 10min, add 15 parts of barium sulfate particles, 25°C, 500r / min magnetic stirring for 10min, then ultrasonic, ultrasonic power 500W, ultrasonic time is 40 cycles (ultrasonic 5s, interval 5s).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com