a c/ti based 4 o 7 Composite nanofiber lithium-sulfur battery cathode material and preparation method thereof

A technology of composite nanofibers and positive electrode materials, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of limited conductivity of sulfur electrodes, and achieve the effects of facilitating industrial production, high conductivity, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

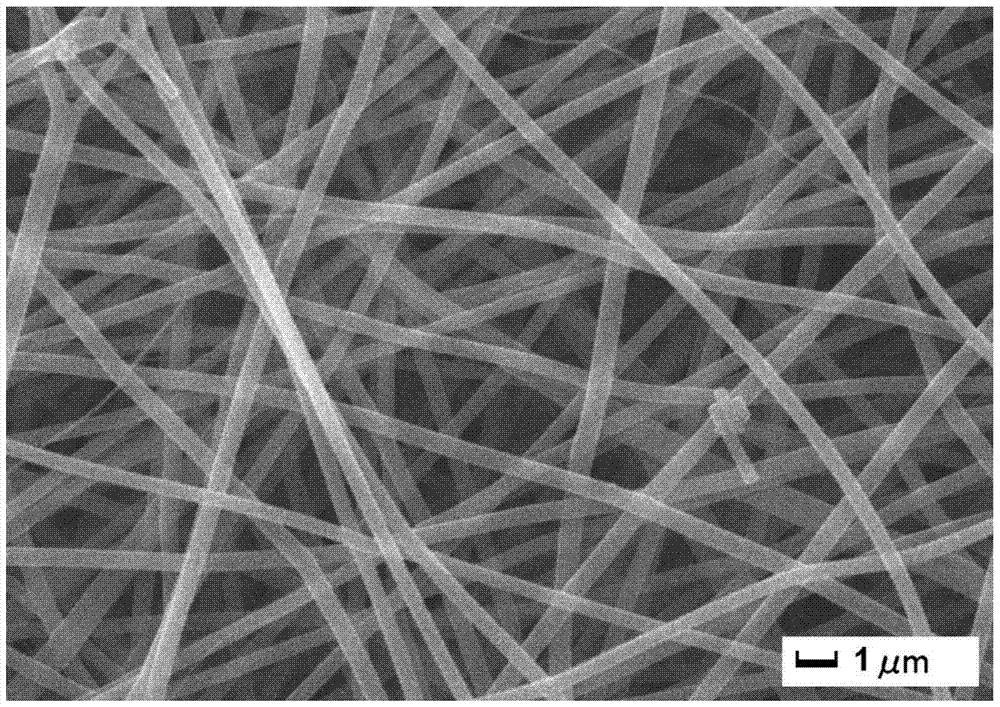

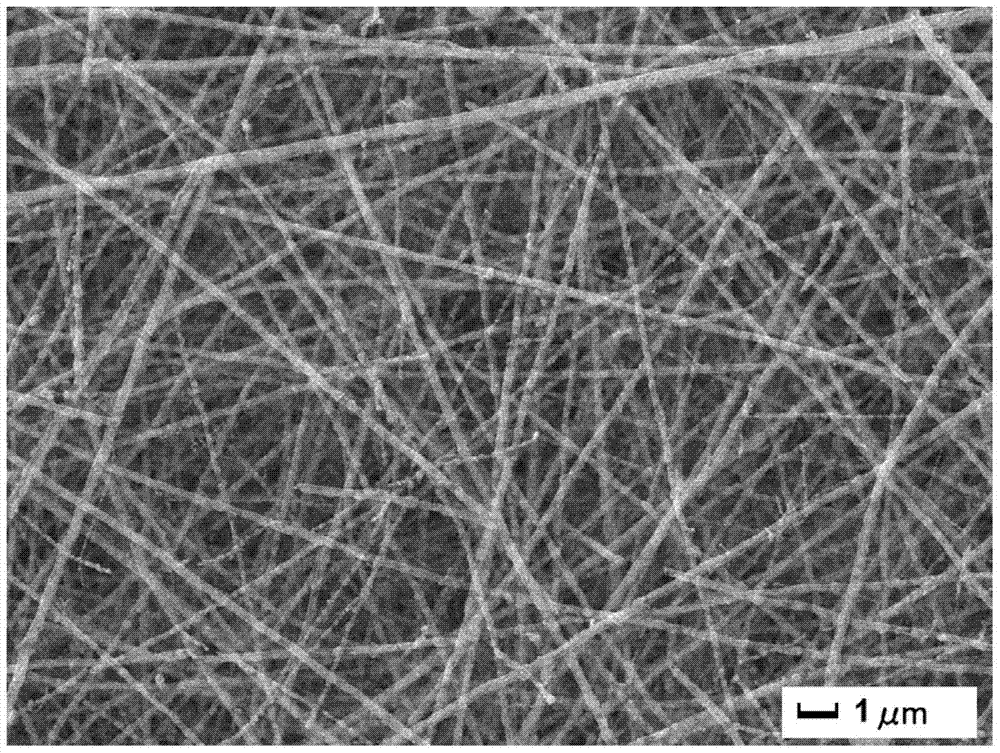

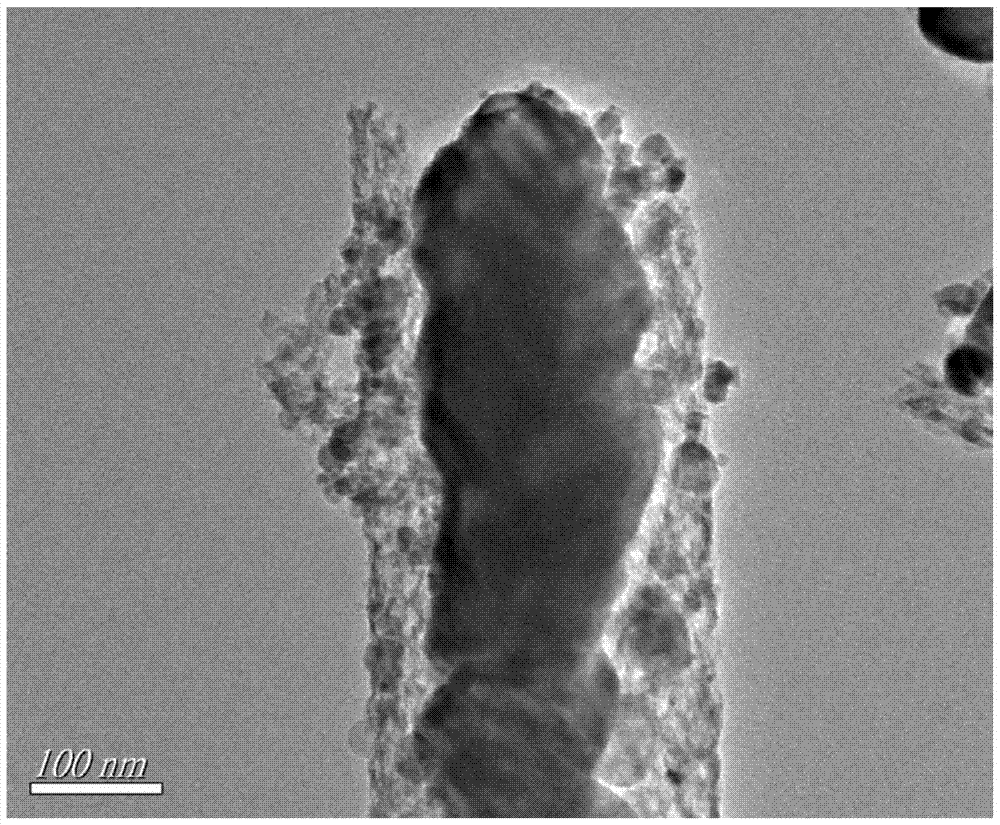

[0033] A kind of C / Ti based on the present invention 4 o 7 The composite nanofiber lithium-sulfur battery cathode material is composed of elemental sulfur and C / Ti with a mass ratio of 2:1 4 o 7 Composite nanofiber composite, C / Ti 4 o 7 The composite nanofiber has a core-shell structure, and the core is Ti 4 o 7 , the shell is porous carbon, the diameter of the composite nanofiber is 150nm, the length is 25μm, the pore diameter is 15nm, and the specific surface area is 158m 2 / g.

[0034] The preparation method of the lithium-sulfur battery positive electrode material of the present embodiment comprises the following steps:

[0035](1) Dissolving 2g of polyvinylpyrrolidone (PVP, with a weight average molecular weight of 40,000) in 38g of absolute ethanol to prepare a PVP solution with a mass fraction of 5%; 6mL of tetrabutyl titanate and 3mL of acetic acid were mixed uniformly to form a yellow Tetrabutyl titanate / acetic acid mixed solution.

[0036] (2) Slowly add the...

Embodiment 2

[0047] The positive electrode material of the lithium-sulfur battery in this embodiment is composed of elemental sulfur and C / Ti with a mass ratio of 3:1. 4 o 7 Composite nanofiber composite, C / Ti 4 o 7 The composite nanofiber has a core-shell structure, and the core is Ti 4 o 7 , the shell is porous carbon, C / Ti 4 o 7 The diameter of the composite nanofiber is 210nm, the length is 15μm, the pore diameter is 8nm, and the specific surface area is 118m 2 / g.

[0048] The preparation method of the lithium-sulfur battery positive electrode material of the present embodiment comprises the following steps:

[0049] (1) Dissolving 2g of polyvinylpyrrolidone (PVP, with a weight average molecular weight of 40,000) in 38g of absolute ethanol to prepare a PVP solution with a mass fraction of 5%; 6mL of tetrabutyl titanate and 3mL of acetic acid were mixed uniformly to form a yellow Tetrabutyl titanate / acetic acid mixed solution.

[0050] (2) Slowly add the tetrabutyl titanate / ac...

Embodiment 3

[0056] Based on C / Ti prepared in this embodiment 4 o 7 The composite nanofiber lithium-sulfur battery cathode material is composed of elemental sulfur and C / Ti with a mass ratio of 2:1 4 o 7 Composite nanofiber composite, C / Ti 4 o 7 The composite nanofiber has a core-shell structure, and the core is Ti 4 o 7 , the shell is porous carbon, C / Ti 4 o 7 The diameter of the composite nanofiber is 135nm, the length is 28μm, the pore size is 12nm, and the specific surface area is 175m 2 / g.

[0057] The preparation method of the lithium-sulfur battery positive electrode material of the present embodiment comprises the following steps:

[0058] (1) Dissolve 1.5g of polyvinylpyrrolidone (PVP, with a weight average molecular weight of 40,000) in 21g of absolute ethanol to prepare a PVP solution with a mass fraction of 6.7%; mix 5mL of tetrabutyl titanate and 2.5mL of acetic acid to form Yellow tetrabutyl titanate / acetic acid mixed solution.

[0059] (2) Slowly add the tetrabut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com