Titanate nanotube SPME coating and preparation method and application thereof

A technology of titanate nanotubes and coatings, applied in the field of analysis and detection, to achieve the effects of improving adsorption and extraction efficiency, good enrichment, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

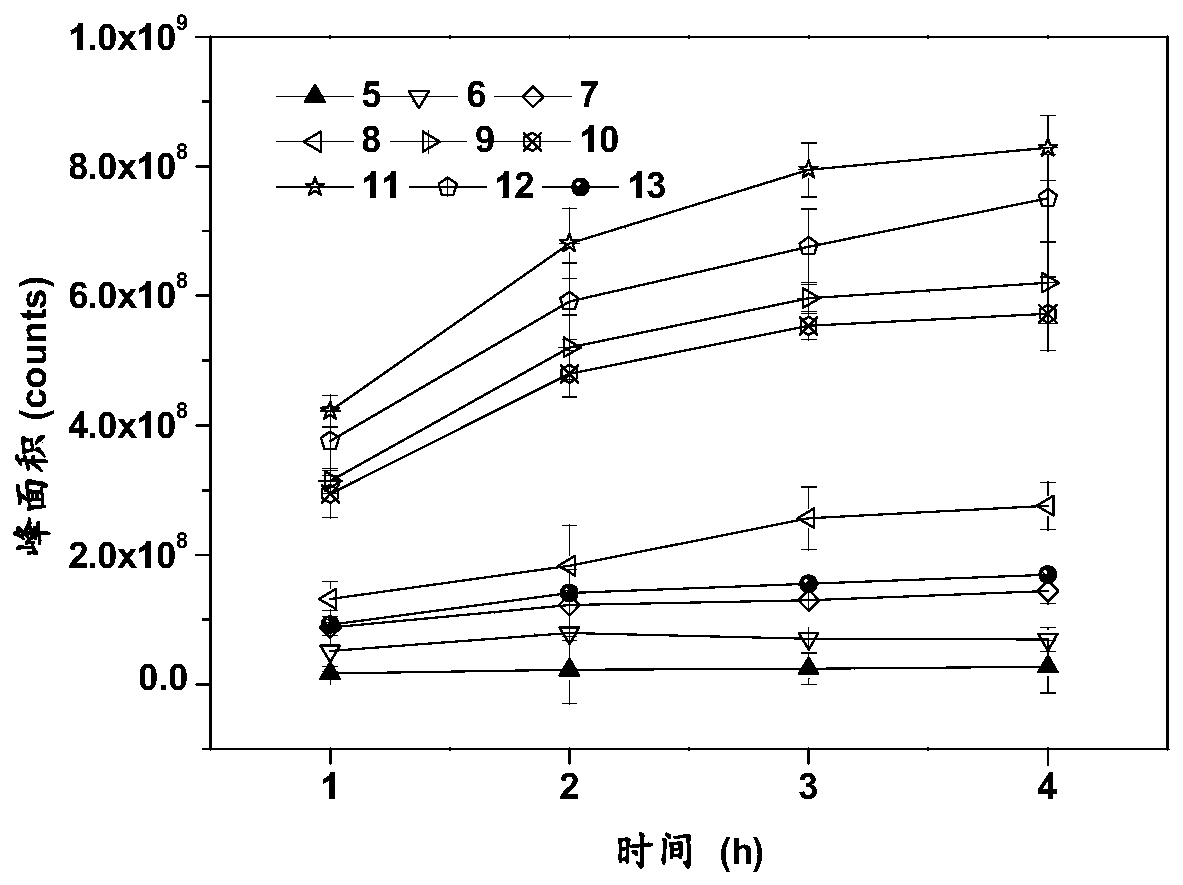

Examples

Embodiment Construction

[0028] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

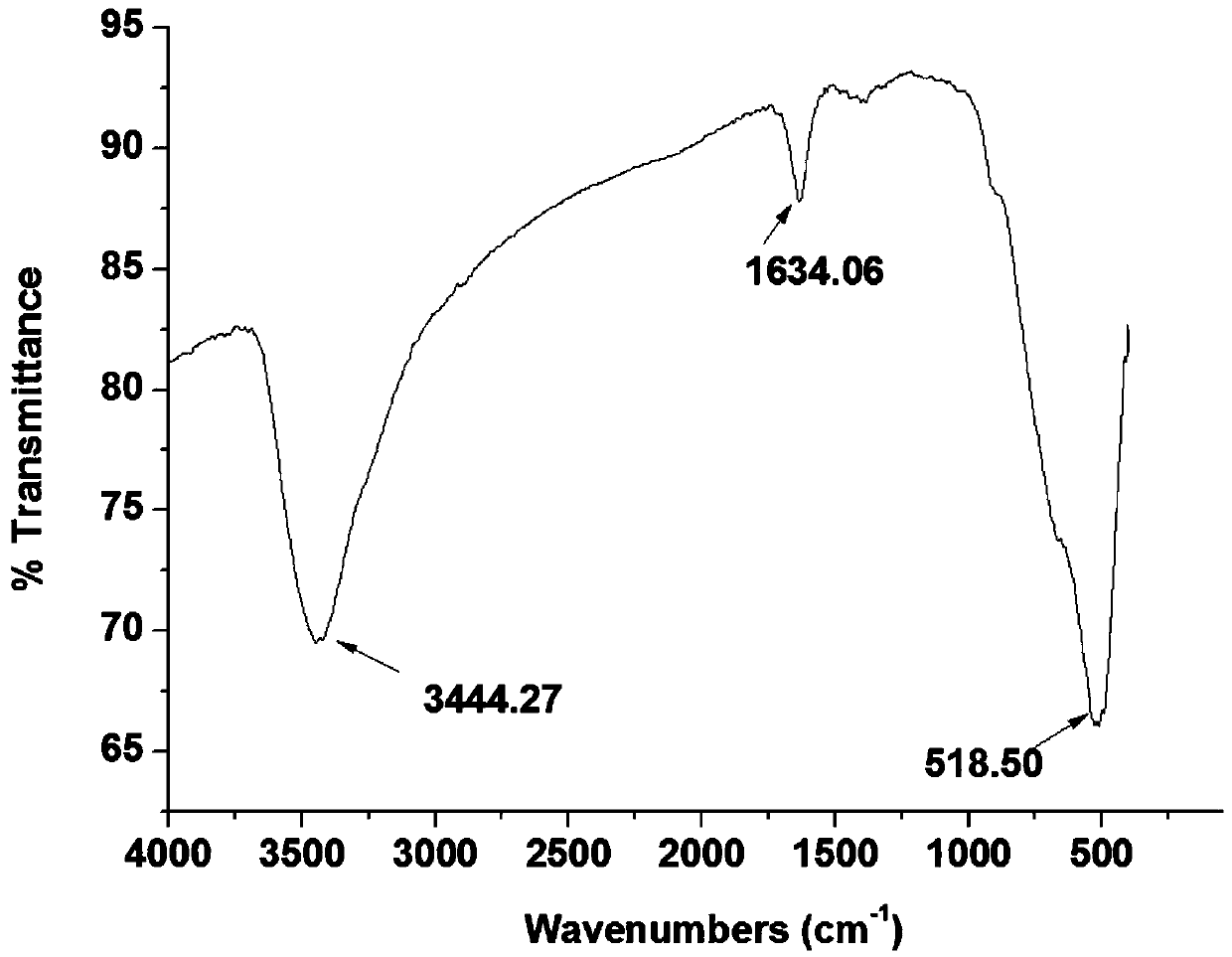

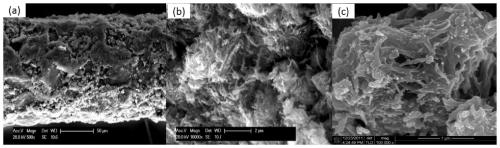

[0029] An embodiment of the present invention is: a titanate nanotube SPME coating, the coating includes a titanate nanotube layer attached to a quartz fiber.

[0030] The preparation method of described coating is as follows:

[0031] 1. Treatment of quartz fiber: take a quartz fiber about 20cm long (diameter 140μm, Hebei Yongnian Ruifeng Chromatography Device Co., Ltd.), immerse the front 2cm part in acetone (purchased from Sinopharm Chemical Reagent Co., Ltd.) solution for about 5min , wash off after peeling off the outer polyimide coating. Take out the quartz fiber processed by the above steps, coat a layer of polyimide resin (purchased from Agilent Company) on the surface of the fiber, and then uniformly stain with titanate nanotubes (obtained from the Nat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com