Multifunctional composite material based on graphene and polymer fibers and preparation method and application thereof

A technology of polymer fibers and composite materials, which is applied in the field of multifunctional composite materials based on graphene and polymer fibers and its preparation and application, can solve the problem of not having dual functions of high thermal conductivity and electromagnetic shielding and excellent mechanical properties, Poor mechanical properties and other problems, to achieve the effects of accelerating sulfur reaction kinetics, inhibiting shuttle, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

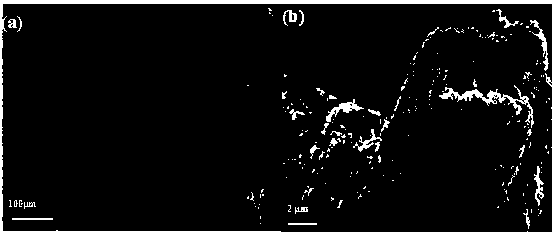

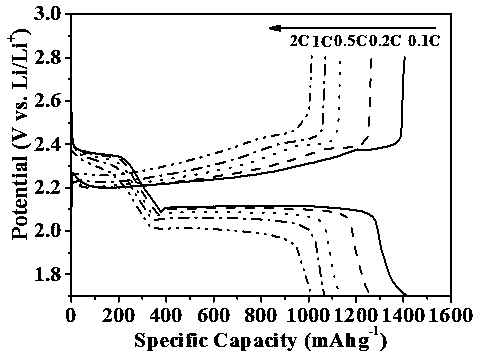

[0069] (1) The obtained commercial natural bamboo fiber cloth was cut into a size of 8 × 4 cm, washed with deionized water and dried at 80 °C for later use. The graphene slurry prepared by electrochemical method was ultrasonicated and the concentration was 4 mg mL -1 Graphene aqueous solution, dissolving urea in deionized water to obtain a 40% solution, taking graphene solution and urea solution at a volume ratio of 1:2 to prepare a homogeneous mixture. The washed bamboo fiber cloth was immersed in the mixture to fully absorb the self-assembly, and then freeze-dried to remove water. A three-dimensional network current collector composed of nitrogen-doped core-shell carbon fibers was prepared by processing at 900 °C under an inert atmosphere. figure 1 The SEM picture in the middle is the topography of the three-dimensional current collector, and it can be seen that it has a core-shell fiber structure. (2) A three-dimensional network current collector composed of nitrogen-dope...

Embodiment 2

[0071] (1) The obtained commercial natural bamboo fiber cloth was cut into a size of 8 × 4 cm, washed with deionized water and dried at 80 °C for later use. The graphene slurry prepared by electrochemical method was ultrasonicated and the concentration was 4 mg mL -1 Graphene aqueous solution, dissolving dopamine hydrochloride in deionized water to obtain a 10% solution, taking graphene solution and urea solution with a volume ratio of 1:2 to prepare a uniform mixed solution. The washed bamboo fiber cloth was immersed in the mixture to fully absorb the self-assembly, and then freeze-dried to remove water. A three-dimensional network current collector composed of nitrogen-doped core-shell carbon fibers was prepared by processing at 900 °C under an inert atmosphere. (2) A three-dimensional network current collector composed of nitrogen-doped core-shell carbon fibers is placed in a carbon disulfide solution of elemental sulfur (S 8 / CS 2 ), after evaporating the solvent and tr...

Embodiment 3

[0073] (1) Cut the obtained bacterial cellulose into a size of 10×5 cm and use 0.1 mol L -1The sodium hydroxide solution was cooked at 80 °C for 1 h to remove bacteria and freeze-dried for later use. Ultrasonic the graphene slurry prepared by the electrochemical method and configure the concentration to be 4 mgmL -1 Graphene aqueous solution, dissolving urea in deionized water to obtain a 10% solution, taking graphene solution and urea solution at a volume ratio of 1:2 to prepare a homogeneous mixture. The washed bamboo fiber cloth was immersed in the mixture to fully absorb the self-assembly, and then freeze-dried to remove water. A three-dimensional network current collector composed of nitrogen-doped core-shell carbon fibers was prepared by processing at 900 °C under an inert atmosphere. (2) A three-dimensional network current collector composed of nitrogen-doped core-shell carbon fibers is placed in a carbon disulfide solution of elemental sulfur (S 8 / CS 2 ), after ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com