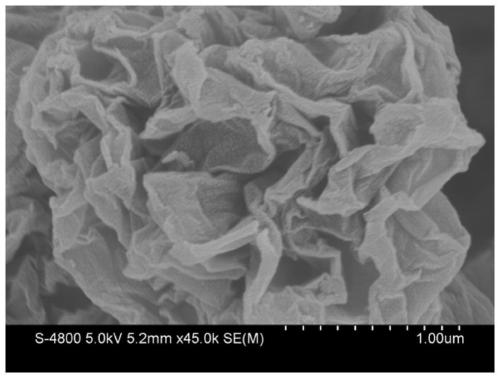

Spherical-like nitrogen-doped reduced graphene oxide material and application thereof

A nitrogen doping and graphene technology, applied in graphene, electrical components, battery electrodes, etc., can solve the problems of reducing polysulfide adsorption capacity, reducing accessible active sites, and uneven distribution of active materials, so as to avoid Loss of specific surface area and active sites, mitigation of shuttle effects, avoidance of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Improved Hummers method: at room temperature, add 4g graphite to 160mL concentrated sulfuric acid (96wt%) and stir for 12h, then add 5gNaNO 3 Mix evenly, then slowly add 18g of potassium permanganate powder into the above mixed solution within 2h, use a water bath to control the temperature to 7°C, let it stand for 4 days, add 300mL of hydrogen peroxide solution (10wt%) and 100mL of hydrochloric acid solution (10wt%) and stir Uniform, then diluted with deionized water and centrifuged to obtain a weakly acidic graphene oxide aqueous solution with a concentration of 6mg / mL (the centrifuge model is H / T16MM, the speed control is 10000rpm, 5min / time);

[0034] (2) Continuously ultrasonically homogenize the graphene oxide aqueous solution for 7 hours (the ultrasonic machine model is KQ-300DE, the ultrasonic power is set to 100%, and the control temperature is lower than 40°C), and it is processed by a BILON-6000Y spray dryer, The inlet temperature is set to 170°C, the out...

Embodiment 2

[0041] (1) Improved Hummers method: at room temperature, add 3g graphite to 150mL concentrated sulfuric acid (96wt%) and stir for 16h, then add 4gNaNO 3 Mix evenly, then slowly add 16g of potassium permanganate powder into the above mixed solution within 2h, use a water bath to control the temperature to 5°C, let it stand for 4 days, then add 500mL of hydrogen peroxide solution (3wt%) and 200mL of hydrochloric acid solution (5wt%) Stir evenly, then dilute and centrifuge with deionized water to obtain a weakly acidic graphene oxide aqueous solution with a concentration of 0.5mg / mL (the centrifuge model is H / T16MM, the speed is controlled at 8000rpm, 15min / time);

[0042] (2) Continuously ultrasonically homogenize the graphene oxide aqueous solution for 4 hours (the ultrasonic machine model is KQ-300DE, the ultrasonic power is set to 100%, and the control temperature is lower than 40°C), and it is processed by a BILON-6000Y spray dryer, The inlet temperature is set to 150°C, the...

Embodiment 3

[0048] (1) Improved Hummers method: at room temperature, add 4g graphite to 150mL concentrated sulfuric acid (96wt%) and stir for 16h, then add 4gNaNO 3 Mix well, then slowly add 16g of potassium permanganate powder into the above mixed solution within 2h, use a water bath to control the temperature to 10°C, let it stand for 4 days, then add 500mL of hydrogen peroxide solution (3wt%) and 200mL of hydrochloric acid solution (10wt%) Stir evenly, then dilute and centrifuge with deionized water to obtain a weakly acidic graphene oxide aqueous solution with a concentration of 12mg / mL (the centrifuge model is H / T16MM, the speed is controlled at 10000rpm, 10min / time);

[0049] (2) Continuously ultrasonicate the graphene oxide aqueous solution for 10 hours (the model of the ultrasonic machine is KQ-300DE, the ultrasonic power is set to 100%, and the control temperature is lower than 40°C), and it is processed by a BILON-6000Y spray dryer, and the inlet temperature is set 170°C, the ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com