Novel floor heating module and processing process

A processing technology and floor heating technology, which is applied in the field of new floor heating modules and their processing technology, can solve the problems of easy damage and low strength of floor heating modules, and achieve the effects of reducing heat loss, smooth operation of floor heating, and uniform heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

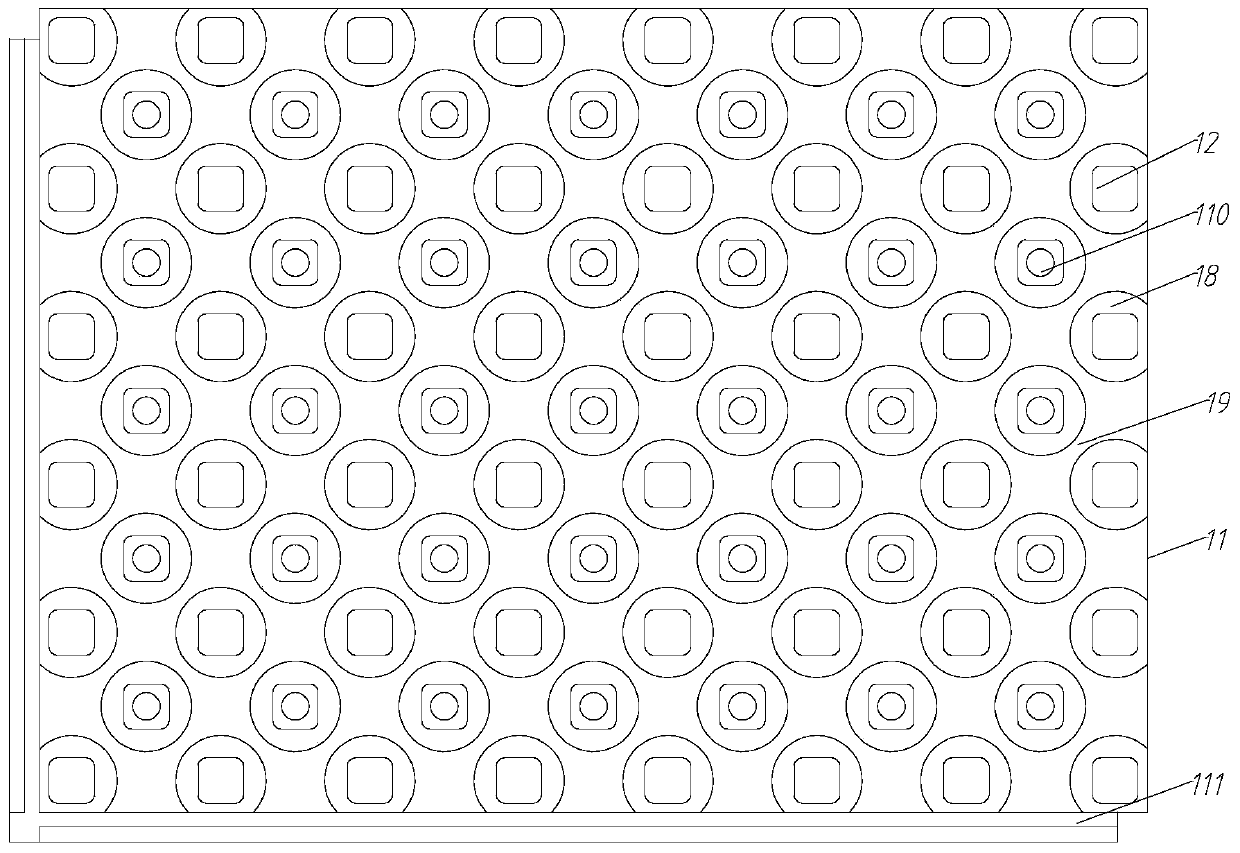

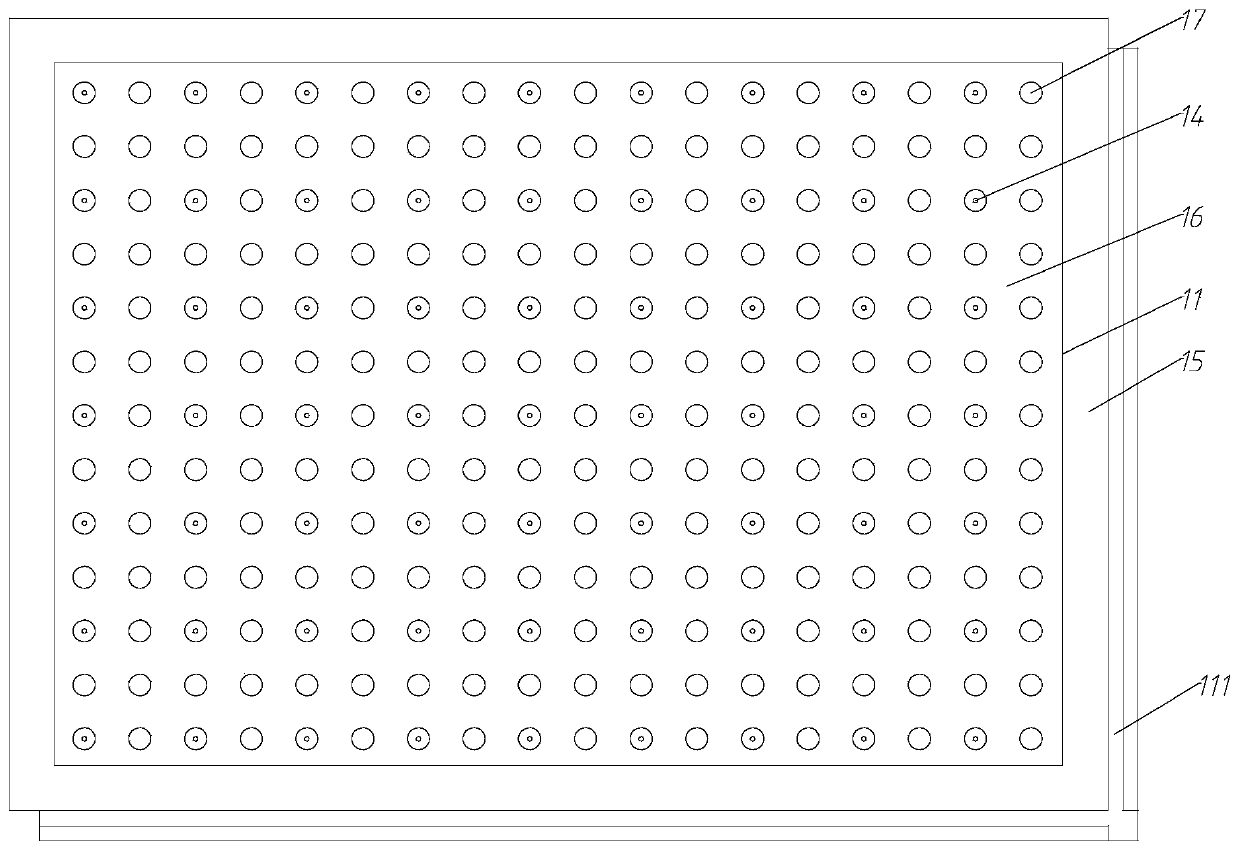

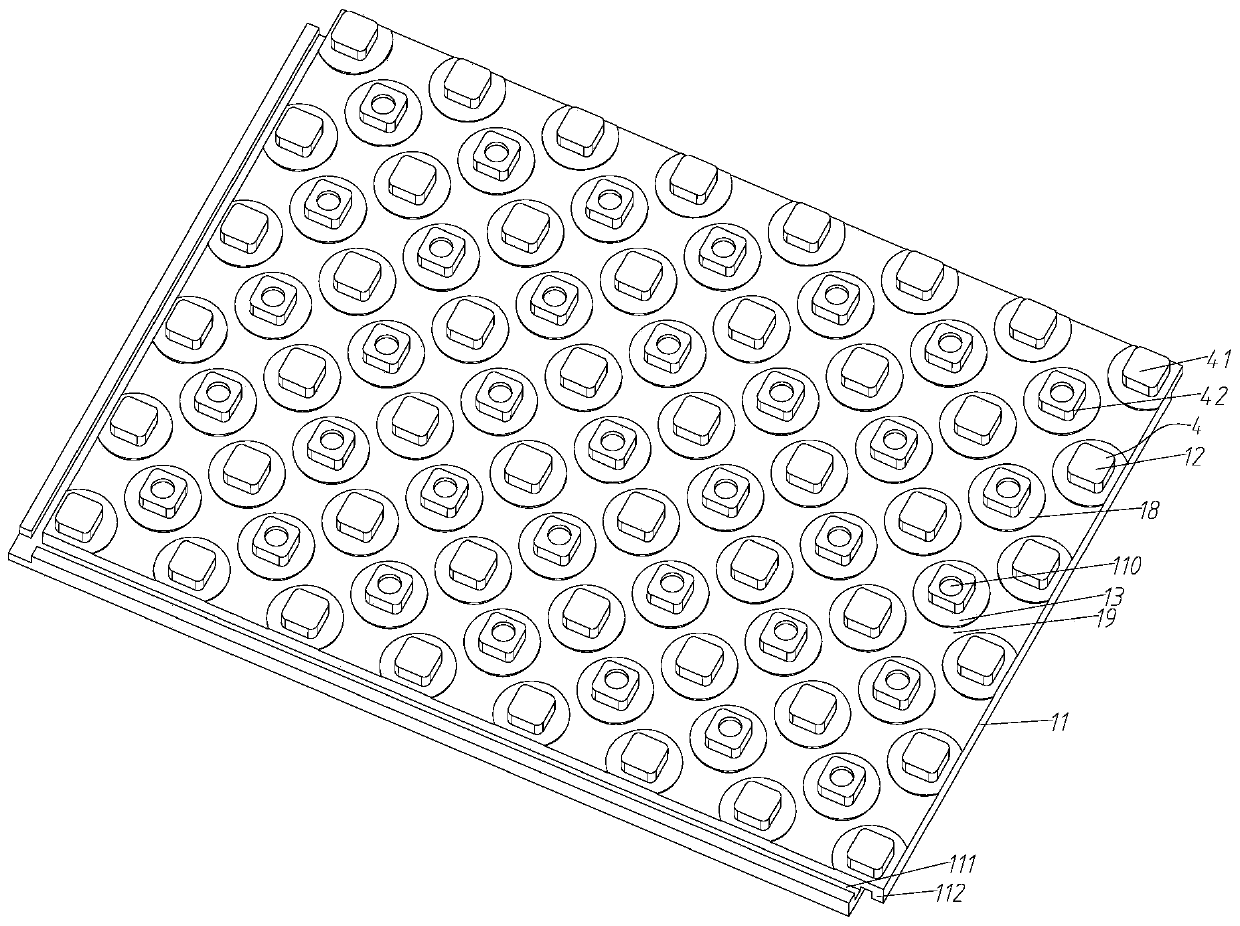

[0044] Such as Figure 1~5 As shown, a new floor heating module includes an insulation layer 1, a flame retardant layer 2 and a reflective layer 3 arranged sequentially from bottom to top,

[0045] Insulation layer 1 comprises insulation layer body 11,

[0046] Limiting columns 12, there are several limiting columns 12, which are evenly arranged on the upper surface of the insulation layer body 11, and a first channel 13 for the floor heating pipe to pass is formed between two adjacent limiting columns 12,

[0047] Adsorption holes 14, there are several adsorption holes 14, are arranged on the lower surface of the insulation layer body 11 to form air passages during positive and negative pressure molding.

[0048] In this embodiment, the floor heating module includes a thermal insulation layer 1, and the floor heating pipes are arranged on the thermal insulation layer 1. The setting of the thermal insulation layer 1 separates the floor heating pipes from the space at the bott...

Embodiment 2

[0065] The processing technology of the floor heating module of embodiment 1 comprises the following steps:

[0066] S1. Foaming polyethylene to obtain insulation layer 1; extruding polyvinyl chloride to obtain flame-retardant layer 2;

[0067] S2. Plating aluminum on the flame retardant layer 2 to obtain the reflective layer 3;

[0068]S3. Using the insulation layer 1 as a mold, heat the flame-retardant layer 2 to 135°C to soften, pressurize to 0.05-0.09MPa, absorb the flame-retardant layer 2 with the aluminum-coated reflective layer 3 onto the insulation layer 1, and air-cool After cooling, a new floor heating module is obtained.

Embodiment 3

[0070] The processing technology of the floor heating module of embodiment 1 comprises the following steps:

[0071] S1. Foaming polystyrene to obtain an insulation layer 1; extruding polyvinyl chloride to obtain a flame-retardant layer 2;

[0072] S2. Plating aluminum on the flame retardant layer 2 to obtain the reflective layer 3;

[0073] S3. Using the insulation layer 1 as a mold, heat the flame-retardant layer 2 to 135°C to soften, pressurize to 0.05-0.09MPa, absorb the flame-retardant layer 2 with the aluminum-coated reflective layer 3 onto the insulation layer 1, and cool it with water Finally, a new type of floor heating module is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com