A reduction dezincification method for zinc-containing dust

A technology of dust and dezincification, which is applied to the improvement of process efficiency, furnace, furnace type, etc., can solve the problems of low zinc grade of sub-zinc oxide products, low hydrophilicity of zinc-containing dust, and influence on process economy, etc., to eliminate The effect of reducing the hidden danger of loop formation, shortening the recovery time, and improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

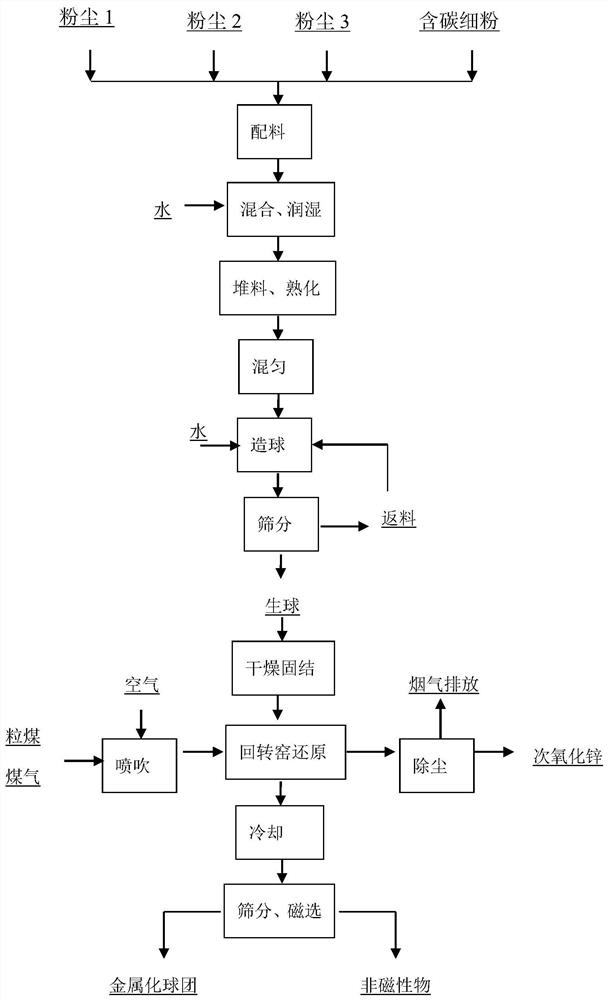

[0059] Aiming at the existing problems, the present invention provides a method for reductive dezincification of zinc-containing dust, comprising the following steps:

[0060] (1) Ingredients: mix blast furnace bag ash, steel-making ladle furnace ash and steel-making converter soot in a weight ratio of 32.42%: 63.46%: 4.12% to obtain mixed dust;

[0061] (2) adding the carbon-containing dedusting ash from the coke oven to the mixed dust prepared in the step (1) to obtain a mixture, the mass ratio of carbon and iron of the mixture is 0.25;

[0062] (3) add water to the mixture prepared in the step (2) and carry out wetting, the addition of the water accounts for 10% of the total weight of the mixture, and the wetting time is 10min, then the mixture is stored and Cover the material and mature for 20 minutes, and the temperature of the material will rise by about 15°C;

[0063] (4) Add 1% composite binder to the mixture and mix evenly to obtain a mixture. The composite binder in...

Embodiment 2

[0070] Aiming at the existing problems, the present invention provides a method for reductive dezincification of zinc-containing dust, comprising the following steps:

[0071] (1) Ingredients: mix blast furnace bag ash, steelmaking ladle ash and steelmaking converter dust in a weight ratio of 32.42%: 63.46%: 4.12% to obtain zinc-containing dust;

[0072] (2) adding finely ground bituminous coal (for changing the amount of internal carbon) to the zinc-containing dust prepared in the step (1) to obtain a mixture, so that the mass ratio of carbon and iron of the mixture is 0.25;

[0073] (3) add water to the mixture prepared in the step (2) for wetting, the addition of the water accounts for 12% of the total weight of the mixture, and the wetting time is 20min, then the mixture is stored and Cover the material and mature for 30 minutes, and the temperature of the mixture will rise by about 20°C;

[0074] (4) Add 0.6% composite binder in the cured mixture and mix uniformly to obt...

Embodiment 3

[0084] Aiming at the existing problems, the present invention provides a method for reductive dezincification of zinc-containing dust, comprising the following steps:

[0085] (1) Ingredients: mix blast furnace bag ash, steelmaking ladle ash and steelmaking converter dust in a weight ratio of 32.42%: 63.46%: 4.12% to obtain zinc-containing dust;

[0086] (2) adding the carbon-containing dedusting ash from the coke oven to the zinc-containing dust prepared in the step (1) to obtain a mixture, so that the carbon and iron mass ratio of the mixture are 0.25;

[0087] (3) add water to the mixture prepared in the step (2) for wetting, the addition of the water accounts for 12% of the total weight of the mixture, and the wetting time is 10min, then the mixture is stored and Cover the material and mature for 30 minutes, and the temperature of the mixture will rise by about 20°C;

[0088] (4) Add 0.8% composite binder to the mixture and mix evenly to obtain a mixture. The composite bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| burst temperature | aaaaa | aaaaa |

| burst temperature | aaaaa | aaaaa |

| burst temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com