Suspension emulsion type slick water friction reducing agent and preparation method thereof

A technology of suspending emulsion and slick water, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of complex production process of slick water drag reducing agent, complicated field application operation, unfavorable popularization and use, etc., and achieve good results Appearance, fast dissolution, and the effect of reducing production and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

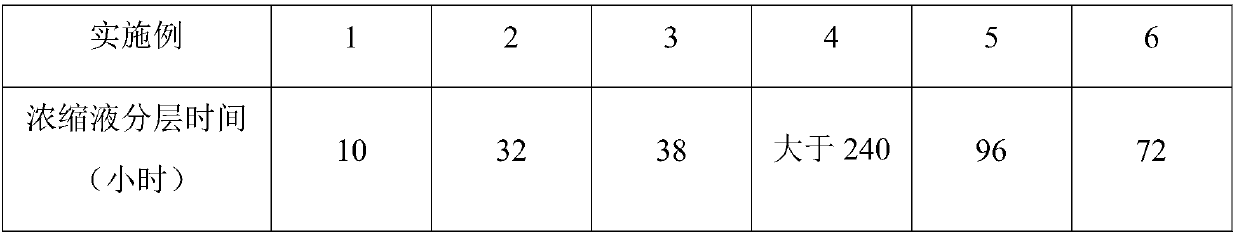

Examples

Embodiment 1

[0036] To prepare a suspension emulsion type slippery water resistance reducing agent, proceed as follows:

[0037] Step 1. Put 40kg of No. 7 white oil in a rotating reactor at 1000 rpm, and heat the No. 7 white oil in the reactor to 55°C;

[0038] Step 2: Add 1kg of organic soil as a stabilizer to the reactor, keep the temperature in the reactor at 55°C, and stir to make the organic soil completely dispersed;

[0039] Step 3: Keep the temperature of the system in the reactor at 55°C, and continue to add 2 kg of triethylene glycol monobutyl ether as a cutting agent to the reactor under stirring conditions;

[0040] Step 4. Adjust and maintain the temperature in the reactor at 55°C while maintaining the rotation speed of 1000 rpm. Slowly add 40 kg of polyacrylamide powder to the reactor. After the powder is added, continue for 10 minutes. It is anionic polyacrylamide;

[0041] Step 5. Adjust and maintain the temperature in the reactor at 50°C, slowly add 1kg of emulsifier to the reactor...

Embodiment 2

[0045] To prepare a suspension emulsion type slippery water resistance reducing agent, proceed as follows:

[0046] Step 1. Put 50kg of No. 7 white oil in a rotating reactor at 1000 rpm, and heat the No. 7 white oil in the reactor to 70°C;

[0047] Step 2: Add 3 kg of organic soil as a stabilizer to the reactor, keep the temperature in the reactor at 70°C, and stir to make the organic soil completely dispersed;

[0048] Step 3. Keep the temperature of the system in the reactor at 70°C, and continue to add 2 kg of butyrolactone as a cutting agent to the reactor under stirring conditions;

[0049] Step 4. Adjust and maintain the temperature in the reactor at 65°C while maintaining the rotation speed of 1000 rpm. Slowly add 50 kg of polyacrylamide powder to the reactor. After the powder is added, continue for 10 minutes. It is a copolymer of salt-resistant monomer and acrylamide monomer; the salt-resistant monomer is N-vinylpyrrolidone.

[0050] Step 5. Adjust and keep the temperature in ...

Embodiment 3

[0054] To prepare a suspension emulsion type slippery water resistance reducing agent, proceed as follows:

[0055] Step 1. Put 45kg of No. 7 white oil in a rotating reactor at 1000 rpm, and raise the No. 7 white oil in the reactor to 60°C;

[0056] Step 2: Add 2kg of organic soil to the reactor as a stabilizer, keep the temperature in the reactor at 60°C, and stir to make the organic soil completely dispersed;

[0057] Step 3: Keep the temperature of the system in the reactor at 60°C, and continue to add 1.5 kg of butyrolactone as a cutting agent to the reactor under stirring conditions;

[0058] Step 4. Keep the temperature in the reactor at 60°C while maintaining the rotation speed of 1000 rpm. Slowly add 45kg of polyacrylamide powder to the reactor. After the powder is added, continue for 10 minutes. The polyacrylamide is anionic Polyacrylamide

[0059] Step 5. Adjust and maintain the temperature in the reactor at 60°C. Slowly add 4kg of emulsifier to the reactor, and then keep the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| resistance reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com