Curable resin composition, prepreg, cured product, laminate, and build-up film

A hardening resin and composition technology, applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve the problems of high dielectric loss, no research, low heat resistance, etc., to achieve Effects of low dielectric loss tangent, high glass transition temperature, and low thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

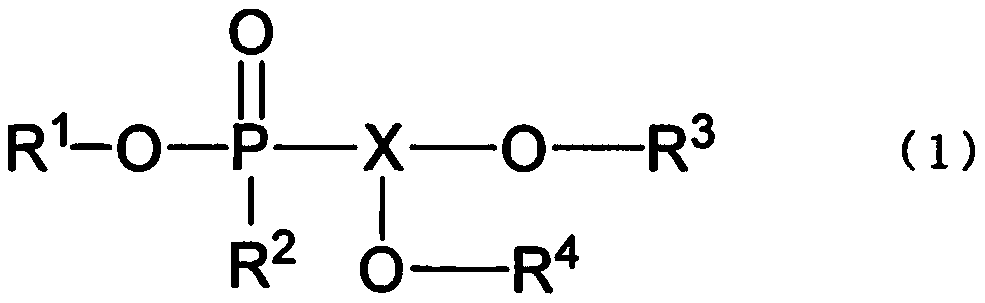

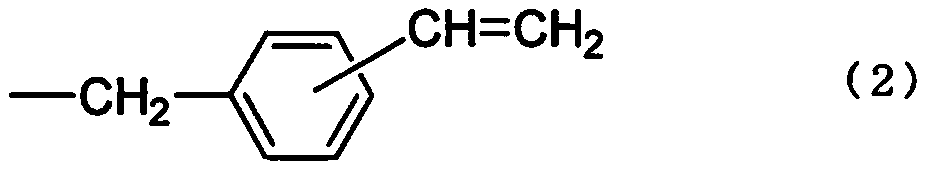

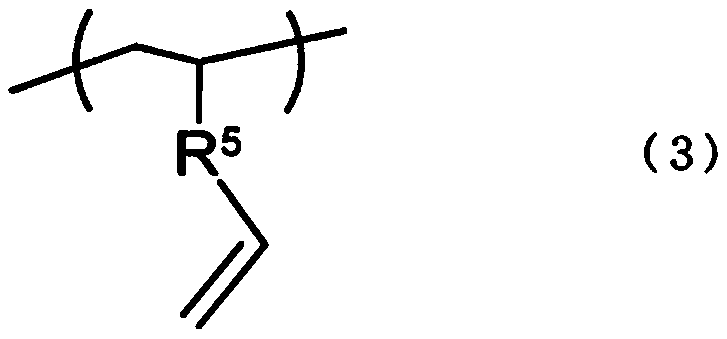

Method used

Image

Examples

Embodiment 1~ Embodiment 6、 comparative example 1~ comparative example 5

[0161] About Example 1-Example 6 and Comparative Example 1-Comparative Example 5, the resin varnish which has the composition shown in Table 1 was prepared. In Table 1, the compounded amount is % by weight except for the initiator (phr), and the phosphorus content rate is % by weight with respect to the total amount of (A) component and (B) component.

[0162] The resin varnish was impregnated with glass cloth (7628 type manufactured by Nittobo; H258), and dried by heating at 130° C. for 5 minutes to obtain a prepreg.

[0163] The obtained 8 prepregs were stacked up and down with copper foil (manufactured by Mitsui Metal Mining Co., Ltd., 3EC-III, thickness 35 μm), and vacuum pressed at 2 MPa under the temperature conditions of 130°C x 15 minutes + 190°C x 80 minutes, A 1.6 mm thick laminate was obtained. Table 1 shows the results of the glass transition temperature and flame retardancy of the laminate.

[0164] Then, the obtained prepreg was pulverized, and a 100-mesh powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com