A kind of magnesia high temperature ceramic soldering material

A technology of high-temperature ceramics and welding fillers, which is applied in the field of high-temperature kiln repairs, can solve problems such as poor strength and damage to magnesia refractory bricks, and achieve the effects of strengthening mechanical properties, enhancing cohesion, and good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

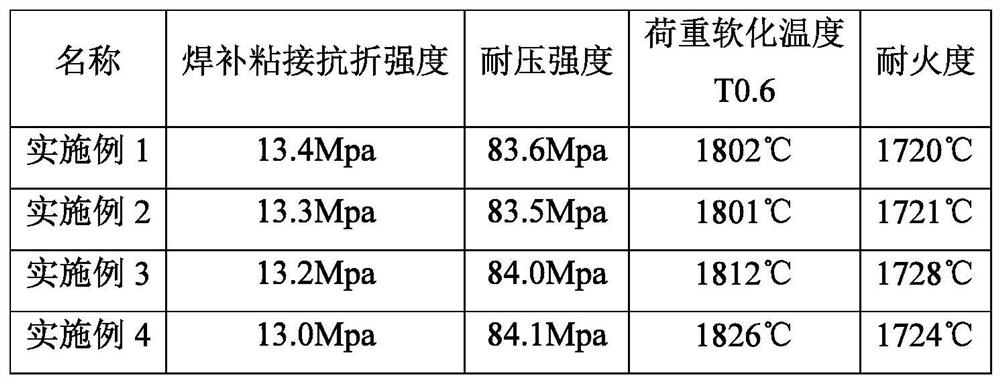

Examples

Embodiment 1

[0028] Weigh 10kg of metal aluminum powder, 30kg of metal magnesium powder, 142.5kg of fused magnesia with a particle size of 0.5-0.3mm, 665kg of fused magnesia with a particle size of 0.3-0.2mm, and fused magnesia with a particle size of 0.2-0.088mm. 66.5 kg of fused magnesia, 76 kg of fused magnesia with a particle size below 0.088 mm, 5 g of No. 10 solid pitch, and 5 g of yttrium oxide powder were mixed and stirred evenly to obtain welding filler 1.

Embodiment 2

[0030] Weigh respectively 40kg of metal aluminum powder, 100kg of metal magnesium powder, 240kg of fused magnesia with a particle size of 0.5-0.3mm, 520kg of fused magnesia with a particle size of 0.3-0.2mm, and electric fused magnesia with a particle size of 0.2-0.088mm. 8 kg of fused magnesia, 32 kg of fused magnesia with a particle size below 0.088 mm, 36 g of No. 10 solid pitch, and 24 g of yttrium oxide powder were mixed and stirred evenly to obtain welding filler 2.

Embodiment 3

[0032] Weigh 60kg of metal aluminum powder, 10kg of metal magnesium powder, 180kg of fused magnesia with a particle size of 0.5-0.3mm, 495kg of fused magnesia with a particle size of 0.3-0.2mm, and electric fused magnesia with a particle size of 0.2-0.088mm. 180kg of fused magnesia, 45kg of fused magnesia with a particle size below 0.088mm, 10g of No. 10 solid pitch and 20g of yttrium oxide powder were mixed and stirred evenly to obtain welding filler 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com