Continuous sulfur heating melting pool

A sulfur pool and hot-melt technology, applied in heat treatment, sulfur compounds, inorganic chemistry, etc., can solve the problems of sulfur slag blocking the conical discharge port of the cyclone, small effective volume of the crude sulfur pool, and capacity limitations, etc., to overcome Blockage, poor effect of overcoming molten sulfur, small footprint for configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

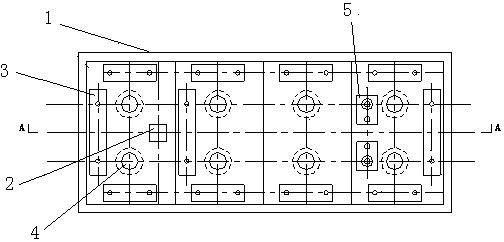

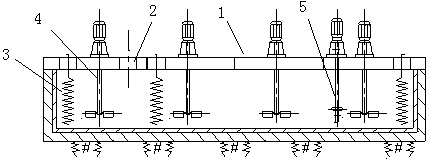

[0031] see figure 1 and figure 2 , the continuous hot molten sulfur pool comprises a closed molten sulfur pool body 1 with a feeding port 2 at the feed end, and a steam coil heater 3 is arranged around the inner wall of the molten sulfur pool body 1; At least one side is also provided with a steam coil heater 3 so that the feed opening 2 is surrounded by the steam coil heater 3 and the steam coil heater 3 on the inner wall of the sulfur melting pool body 1; A stirrer 4 is arranged in the area surrounded by the coil heater 3 .

[0032] The total heat exchange area of the steam coil heaters 3 surrounding the feeding port 2 is 60-70% of the total heat exchange area of all the steam coil heaters 3 inside the sulfur melting pool body 1 .

[0033] The effective volume of the hot molten sulfur pool is 40 to 50 times the volume of sulfur slag treated per hour.

[0034] The steam pressure of the steam coil heater 3 is 650 kPa.

[0035] The discharge end of the molten sulfur po...

Embodiment 2

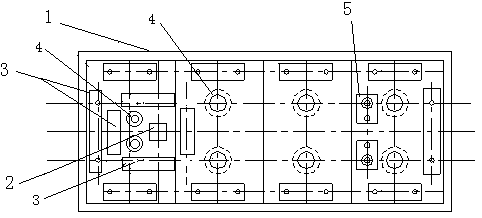

[0040] see image 3 , the continuous hot molten sulfur pool comprises a closed molten sulfur pool body 1 provided with a feeding port 2 at the feed end, and a steam coil heater 3 is provided around the inner wall of the molten sulfur pool body 1; the feeding port 2 is also provided with a steam coil heater 3 around; a stirrer 4 is provided around the feeding port 2 and in the area surrounded by the steam coil heater 3.

[0041] The total heat exchange area of the steam coil heaters 3 surrounding the feeding port 2 is 60%-70% of the total heat exchange area of all the steam coil heaters 3 inside the sulfur melting pool body 1 .

[0042] The effective volume of the hot molten sulfur pool is 40 to 50 times the volume of sulfur slag treated per hour.

[0043] The steam pressure of the steam coil heater 3 is 650 kPa.

[0044] The discharge end of the molten sulfur pool body 1 is provided with a crude sulfur filter pump 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com