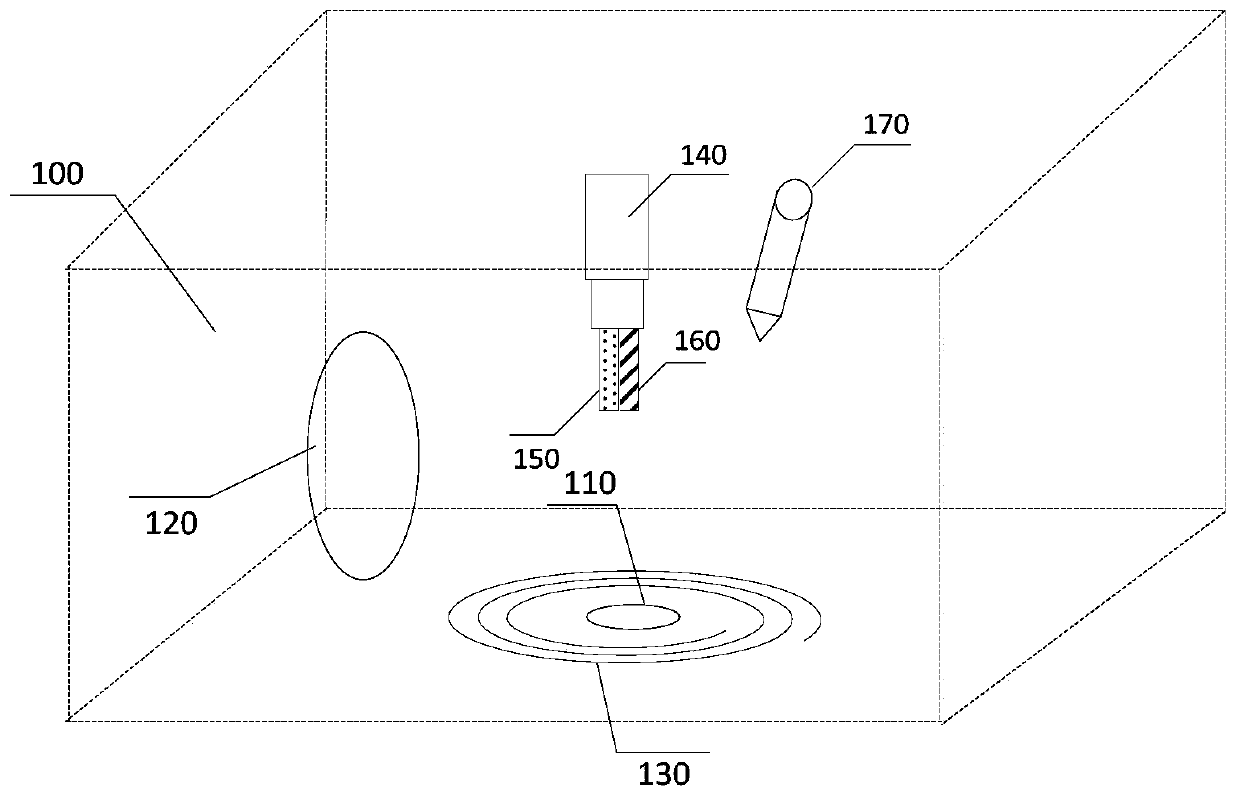

System with food material cleaning device and food material heat treatment device and method for processing food materials

A heat treatment device and cleaning device technology, which is applied in the field of food processing, can solve the problems of the food processing system to be developed, and achieve the effects of ingenious structural design, ecological realization, and accelerated evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0124] In this example, potatoes were processed as follows:

[0125] 1. Put the potatoes to be cleaned into the raw material bin, and then transfer them to the food cleaning device for cleaning.

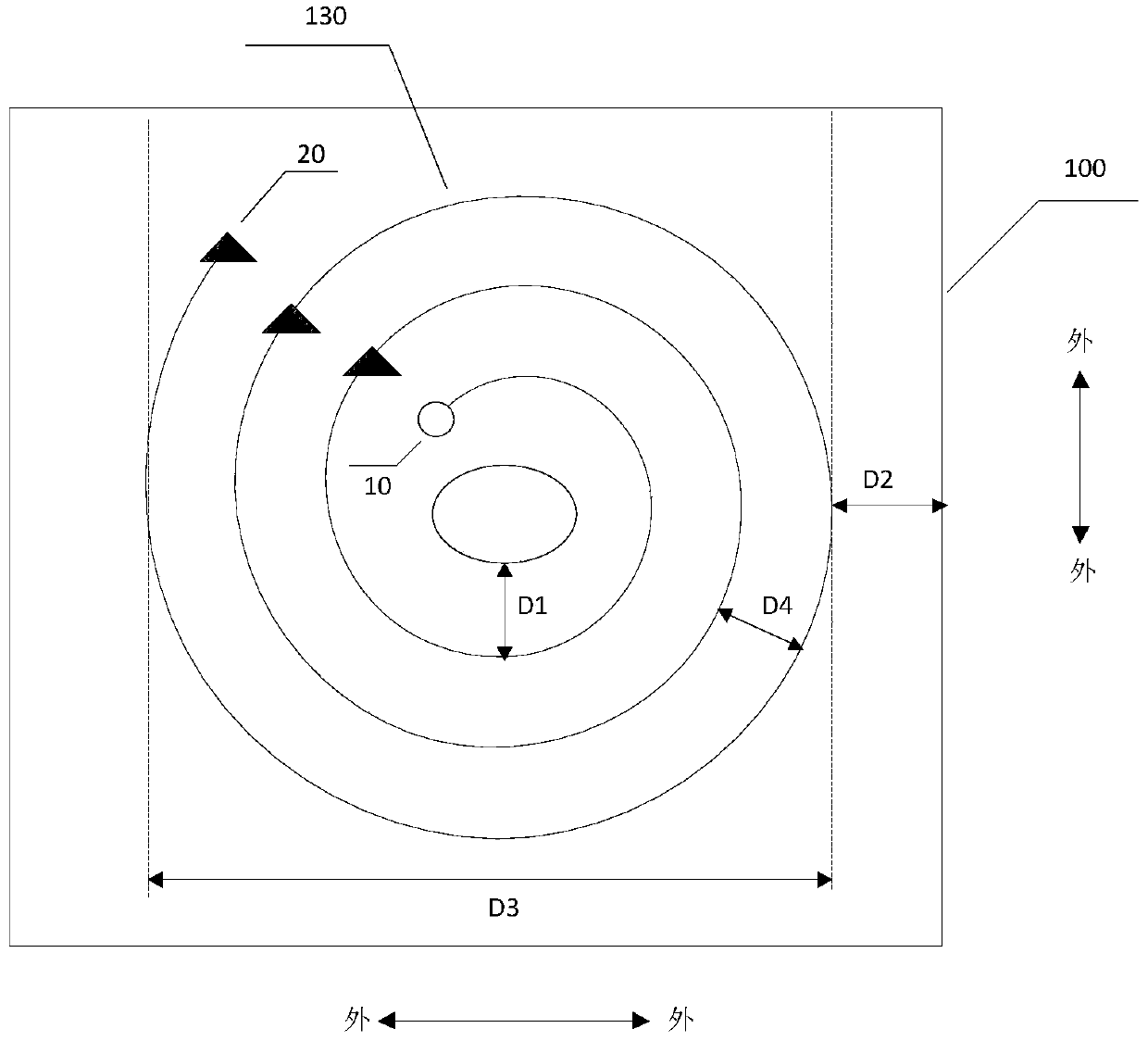

[0126] Among them, the first area and the second area are through holes with a diameter of 3 cm formed by glass, and the height of the two is the same. When the light is irradiated on the first area and the second area, the height of the highest point of the formed aperture from the bottom of the cavity 25% of the total height of the cavity. Specific steps are as follows:

[0127] (1) Control the water inlet part to inject water into the cavity.

[0128] (2) Control the moving parts so that the potatoes are moved into the water at a speed of 10cm / s. When entering the water, turn on the ozone generating part so that ozone is passed into the cavity at a speed of 8L / min. At the same time, turn on the ultrasonic oscillator, power 20Hz. When the potatoes are completely submerged in wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com