Preparation method of hollow mesoporous silica antibacterial agent grafted with guanidine salt polymer

A guanidine salt polymer and silica technology, which is applied in the directions of botanical equipment and methods, chemical instruments and methods, animal repellents, etc., can solve the problem that the combination of hollow mesoporous silica and guanidine salt polymers cannot be realized. and other problems, to achieve the effect of low cost, simple operation process, efficient and broad-spectrum sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

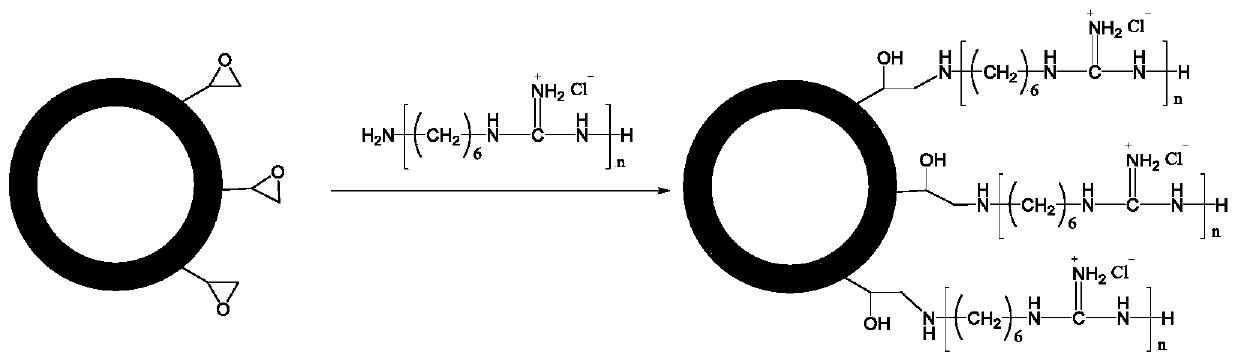

Method used

Image

Examples

Embodiment 1

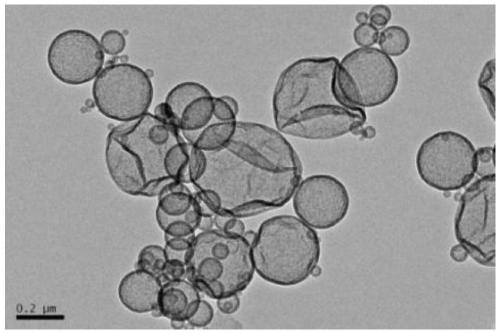

[0031] Weigh 100g of deionized water, 0.5g of emulsifier cetyltrimethylammonium bromide and mix them, fully stir for 20-30min to form a water phase, weigh 13g of tetraethyl orthosilicate, 0.65g of KH560, 1.5g of hydrophobic solvent A Base silicone oil, 0.5g co-stabilizer hexadecane mixed, ultrasonic 15-30min to form an oil phase, slowly add the oil phase to the water phase and continue stirring for 20-30min to obtain a pre-emulsion; under the condition of ice water bath, use a homogeneous emulsifier Emulsify the pre-emulsion at 16,000rpm for 5min to prepare a mini-emulsion; add 0.38g of cross-linking agent triethylamine to the mini-emulsion and stir at room temperature for 24h to obtain epoxy-modified hollow mesoporous silica, which is centrifuged and washed with absolute ethanol at a low speed After 3-5 times, dry it for later use;

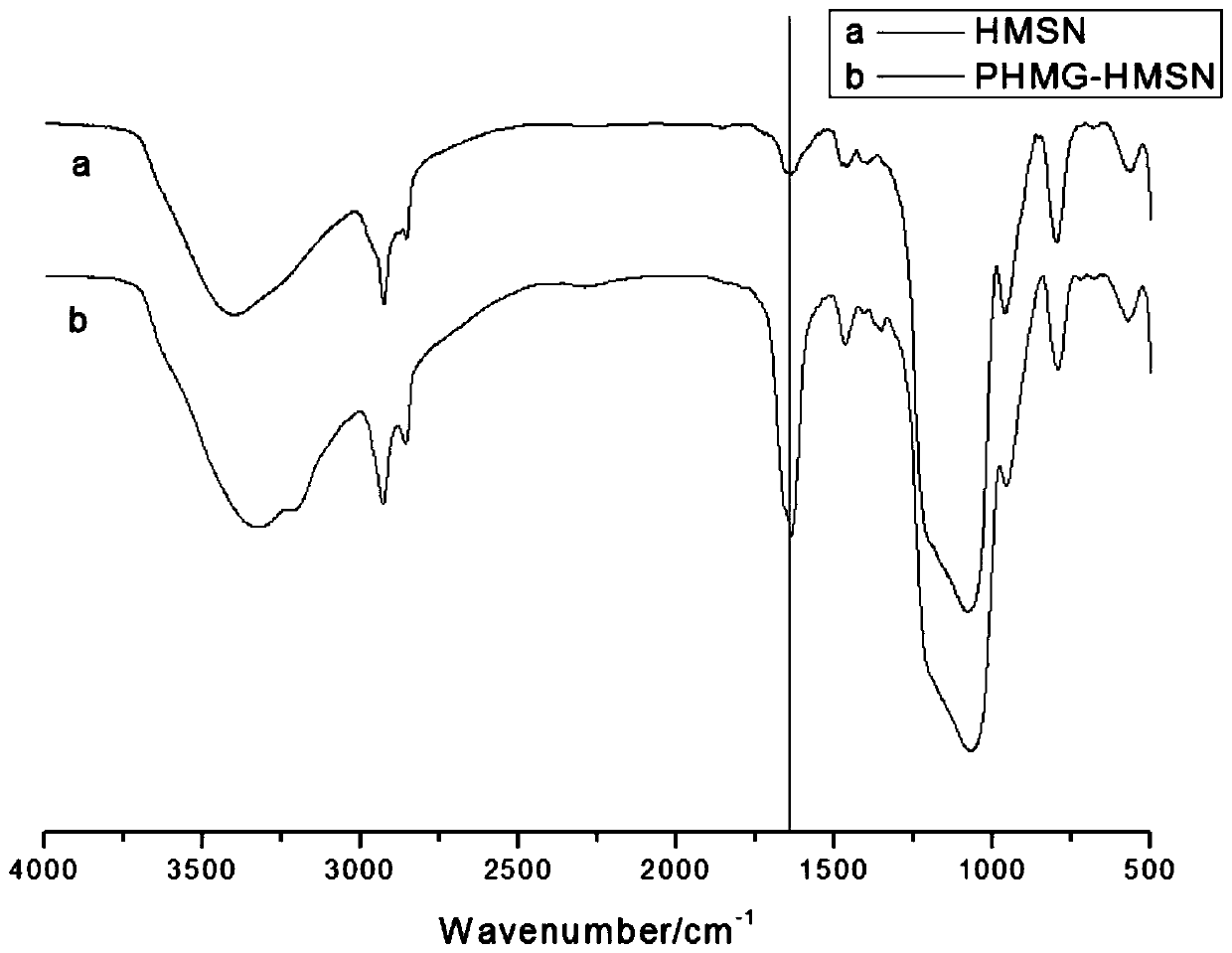

[0032] Ultrasonically disperse 0.2g of epoxy-modified hollow mesoporous silica in 250ml of deionized water, add 3g of 25wt% PHMG aqueous solutio...

Embodiment 2

[0036] Weigh 100g of deionized water, 0.5g of emulsifier cetyltrimethylammonium bromide and mix them, fully stir for 20-30min to form a water phase, weigh 13g of tetraethyl orthosilicate, 1.3g of KH560, 1.5g of hydrophobic solvent A Base silicone oil, 0.5g co-stabilizer hexadecane mixed, ultrasonic 15-30min to form an oil phase, slowly add the oil phase to the water phase and continue stirring for 20-30min to obtain a pre-emulsion; under the condition of ice water bath, use a homogeneous emulsifier Emulsify the pre-emulsion at 16000rpm for 5min to prepare a mini-emulsion; add 0.38g of cross-linking agent triethylamine to the mini-emulsion and stir at room temperature for 24h to obtain epoxy-modified hollow mesoporous silica, which is centrifuged and washed with absolute ethanol at a low speed After 3-5 times, dry it for later use;

[0037] Ultrasonically disperse 0.2g of epoxy-modified hollow mesoporous silica in 250ml of deionized water, add 3g of 25wt% PHMG aqueous solution,...

Embodiment 3

[0041] Weigh 100g of deionized water, 0.5g of emulsifier cetyltrimethylammonium bromide and mix them, stir thoroughly for 20-30min to form a water phase, weigh 13g of tetraethyl orthosilicate, 1.95g of KH560, 1.5g of hydrophobic solvent A Base silicone oil, 0.5g co-stabilizer hexadecane mixed, ultrasonic 15-30min to form an oil phase, slowly add the oil phase to the water phase and continue stirring for 20-30min to obtain a pre-emulsion; under the condition of ice water bath, use a homogeneous emulsifier Emulsify the pre-emulsion at 16,000rpm for 5min to prepare a mini-emulsion; add 0.38g of cross-linking agent triethylamine to the mini-emulsion and stir at room temperature for 24h to obtain epoxy-modified hollow mesoporous silica, which is centrifuged and washed with absolute ethanol at a low speed After 3-5 times, dry it for later use;

[0042] Ultrasonically disperse 0.2g of epoxy-modified hollow mesoporous silica in 250ml of deionized water, add 3g of 25wt% PHMG aqueous so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com