A kind of plant protein friction nanogenerator and its application

A nanogenerator and vegetable protein technology, applied in triboelectric generators, nanotechnology, nanotechnology and other directions, can solve problems such as difficult application, triboelectric properties and mechanisms to be explored, cumbersome processing steps, etc. Simple process, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] 1) First, the preparation of the protein film: the protein is dispersed in an aqueous solution or a concentration of 70%-90% ethanol solution (1-10%, w / w) to prepare a protein solution; then add a mass of Protein 10-60% (w / w) plasticizer (such as glycerin), heated and denatured in a water bath at 60-95°C, stirred for 30-60 minutes, degassed under vacuum for 10 minutes, then poured into a mold and placed in an oven Evaporate to dryness at 30-70°C.

[0040] In the specific implementation, the dried protein film is finally peeled off, and the specific implementation also places the protein film under constant temperature and humidity conditions, so that it can balance the moisture under certain temperature and humidity conditions for subsequent electrical tests.

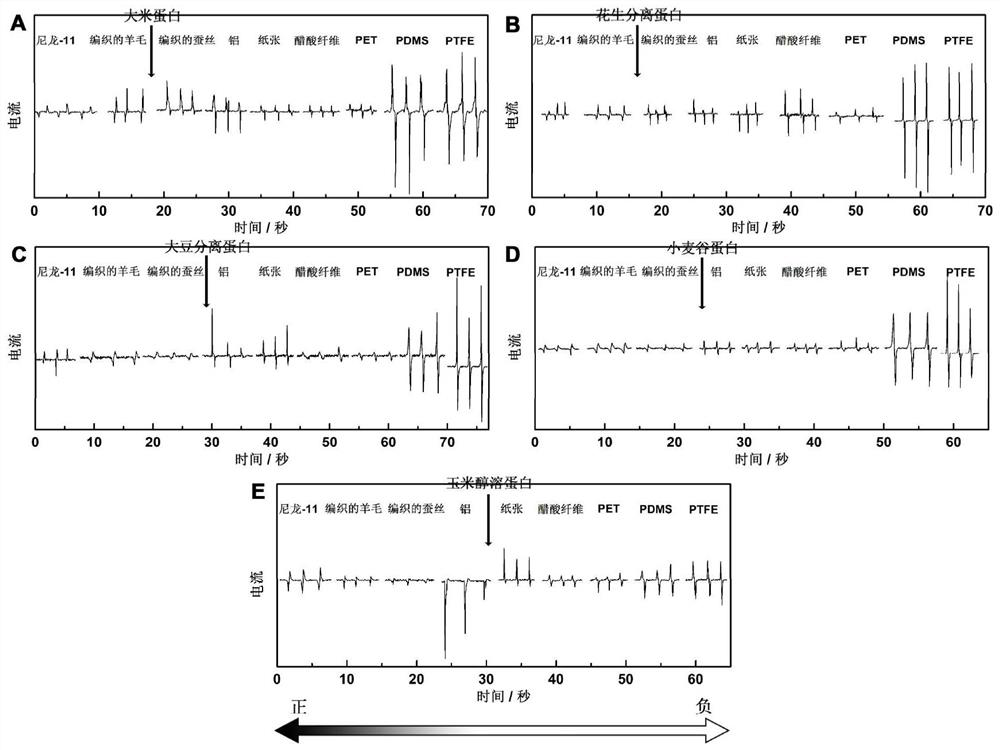

[0041] 2) Triboelectric negative layer: The specific triboelectric negative layer is made of polytetrafluoroethylene (Teflon), polydimethylsiloxane (PDMS), polyvinyl chloride (PVC), polyimide (Kapton), silicon R...

Embodiment 1

[0046] 1) The first is the preparation of the protein film. The film-forming solution is prepared by dispersing rice protein, peanut protein isolate, soybean protein isolate, and wheat gluten in distilled water (5%, w / w). In addition, zein is dispersed in The concentration is 70% ethanol aqueous solution (5%, w / w). Then, 30% (w / w) glycerol with a mass of protein was added to the five protein solutions.

[0047] 2) In the present embodiment, for rice protein, peanut protein isolate, soybean protein isolate, and wheat gluten, the following are specifically: 5g vegetable protein and 1.5g glycerin are mixed in 100mL deionized aqueous solution, and after magnetic stirring for 10 minutes, , and then adjust the pH of the protein precursor solution. The pH value of the protein solution was adjusted to 12 using 1 M sodium hydroxide solution; then the protein solution was heated and stirred at 65 °C for 30 minutes, and degassed under vacuum for 10 minutes to remove air bubbles.

[004...

Embodiment 2

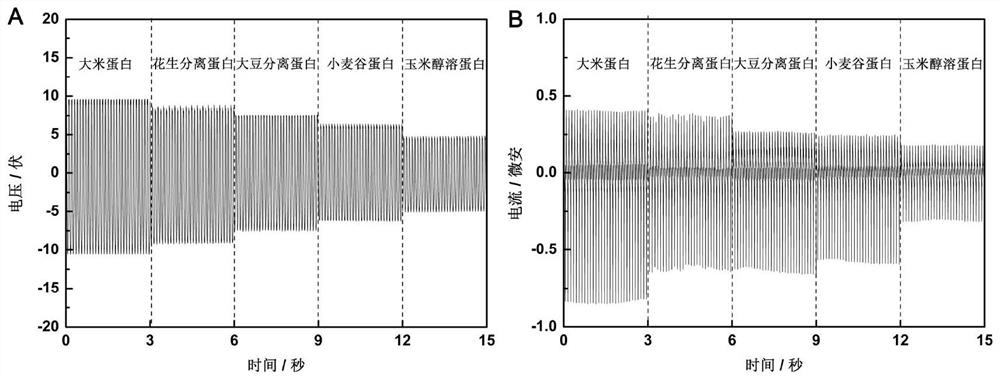

[0053] Taking rice protein as an example, 5 g of rice protein and 1.5 g of glycerol were mixed in 100 mL of deionized aqueous solution, and after magnetic stirring for 10 minutes, the pH of the protein solution was adjusted to 12 using 1 M sodium hydroxide solution. The protein solution was then heated and stirred at 65 °C for 30 min, and degassed under vacuum for 10 min to remove air bubbles. Finally, the final film-forming solution was poured into a circular Teflon mold (3 cm in diameter) and dried in an oven at 60 °C. Finally, the dried film was peeled off and placed in a constant temperature and humidity incubator at 25° C. and 40% relative humidity for 24 hours as a triboelectron-donating layer for testing.

[0054] Preparation of the triboelectric negative layer: the polylactic acid film was cut into a circle with a diameter of 3 cm.

[0055] Preparation of triboelectric nanogenerator: The above-mentioned rice protein film and polylactic acid film were combined to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com