Carbon nanotube enameled wire and application thereof

A technology of carbon nanotubes and carbon nanotube fibers, which is applied in the direction of reducing the size of conductors/cables, bendable conductors, and cable/conductor manufacturing. Effects of current carrying capacity and electrical conductivity, decreased electrical resistance, good flexibility and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

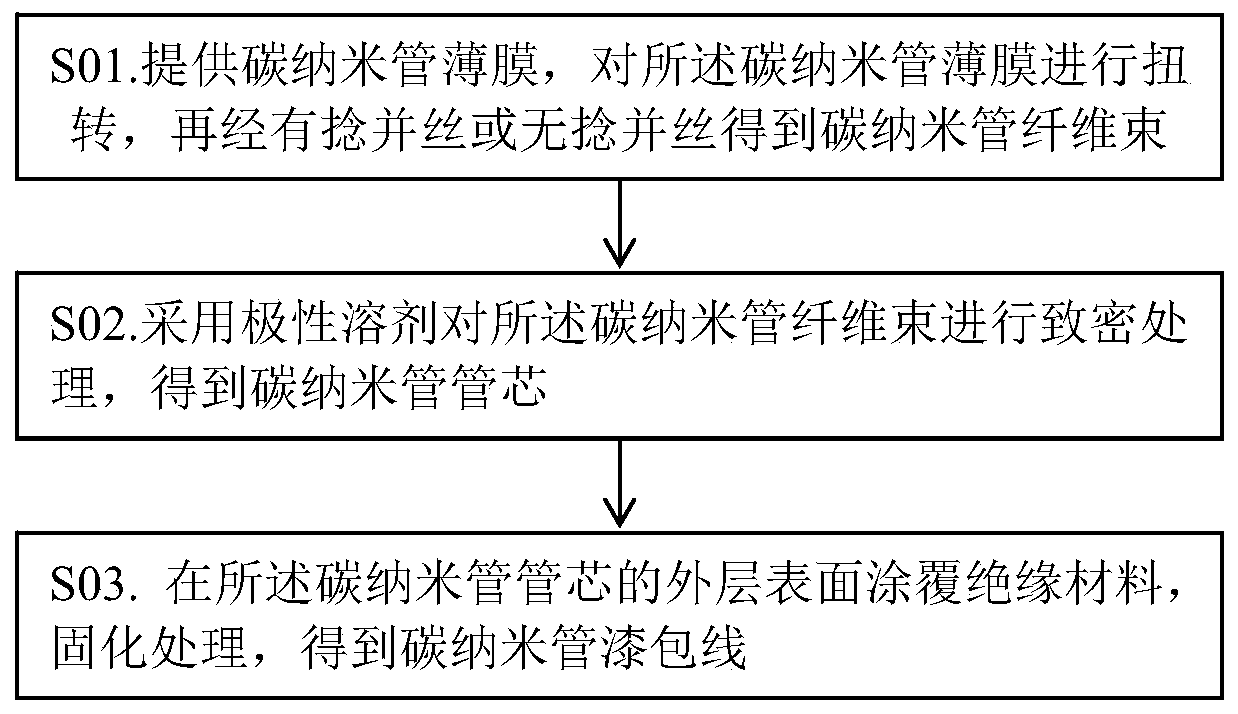

[0053] The preparation method comprises the following steps:

[0054] S01. Provide a carbon nanotube film, twist the carbon nanotube film, and then obtain a carbon nanotube fiber bundle through twisted paralleling or non-twisting paralleling;

[0055] S02. Using a polar solvent to densify the carbon nanotube fiber bundle to obtain a carbon nanotube core;

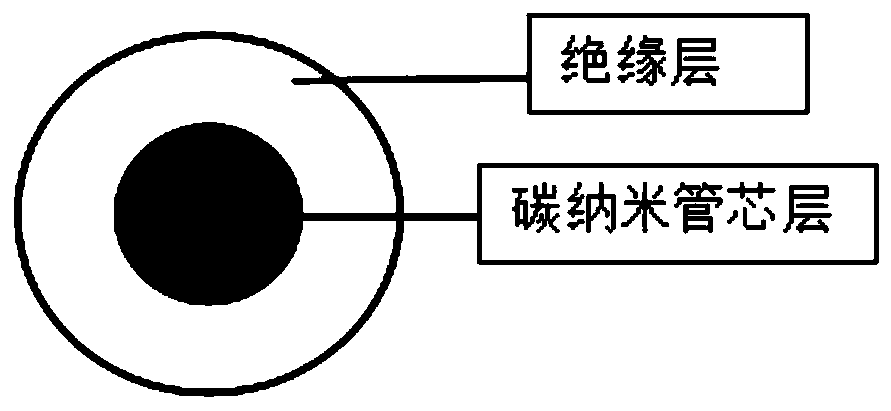

[0056] S03. Coating an insulating material on the surface of the outer layer of the carbon nanotube core, and curing to obtain a carbon nanotube enameled wire.

[0057] In the above step S01, a carbon nanotube film is provided, the carbon nanotube film is twisted to obtain carbon nanotube fibers, and then twisted or untwisted to obtain carbon nanotube fiber bundles. Preferably, mechanically twisting the carbon nanotube film specifically refers to twisting the carbon nanotube film so that the carbon nanotube film becomes a carbon nanotube fiber. Preferably, during the mechanical twisting process, the The twist of mechanical...

Embodiment 1

[0073] A carbon nanotube enameled wire and a preparation method thereof, comprising the following steps:

[0074] Pull out a carbon nanotube film with a width of 7.5 cm and a length of 3 m from the carbon nanotube array;

[0075] Use a twist meter to mechanically twist the above film with a twist of 1200-1500tpm to obtain carbon nanotube fibers with a diameter of about 0.09mm;

[0076] Carry out ethanol solution treatment to above-mentioned carbon nanotube fiber, make it dense;

[0077] For the carbon nanotube fibers after the above treatment, 10 fibers are merged together with a twist of 100tpm, and then a layer of flexible ceramic coating is uniformly coated on the surface, and the sizing rate is 10-30%. The flexible ceramic coating contains 5-30% ceramic The paint is dissolved in water or ethanol, the surface curing condition is 20-30min at room temperature, and the complete curing condition is 72h at room temperature. Finally, carbon nanotube enameled wire is obtained, an...

Embodiment 2

[0079] A carbon nanotube enameled wire and a preparation method thereof, comprising the following steps:

[0080] Pull out a carbon nanotube film with a width of 7.5 cm and a length of 3 m from the carbon nanotube array;

[0081] Use a twist meter to mechanically twist the above film with a twist of 1200-1500tpm to obtain carbon nanotube fibers with a diameter of about 0.09mm;

[0082] Carry out ethanol solution treatment to above-mentioned carbon nanotube fiber, make it dense;

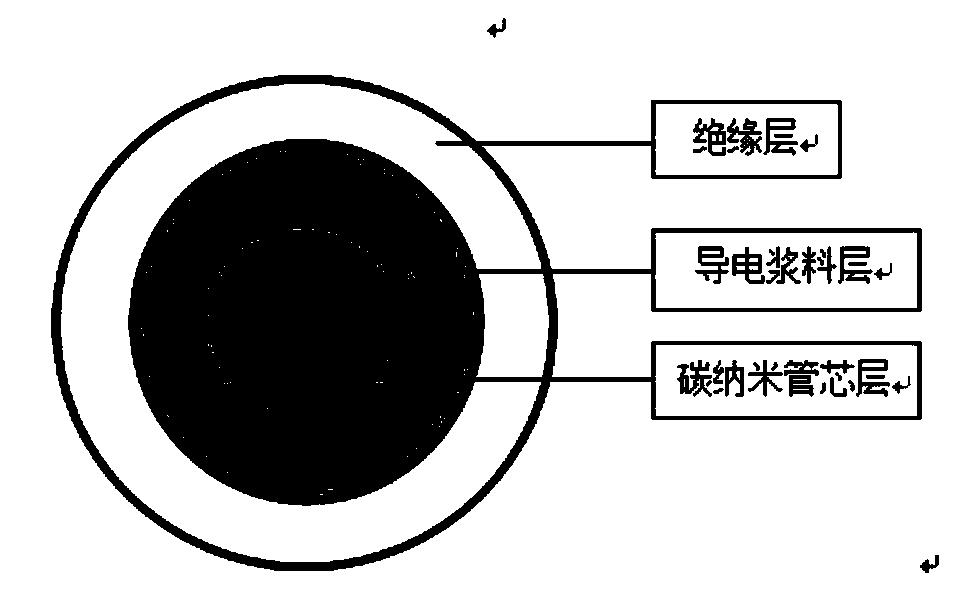

[0083] For the carbon nanotube fibers after the above treatment, 3 fibers are merged together with a twist of 100tpm, and then a layer of conductive silver paste is coated on the surface, the sizing rate is about 70%, and it is dried and cured at 80-100°C for at least half an hour;

[0084] A layer of PVA insulating varnish is coated on the surface of the above-mentioned conductor, and the PVA insulating varnish is a PVA aqueous solution with a concentration of 10%, which is dried and cured at 80°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com