A method for preparing high-purity lanthanum, high-purity cerium and high-purity praseodymium neodymium

A high-purity, neodymium praseodymium technology, applied in the direction of improving process efficiency, can solve the problems of low product purity and high acid-base consumption, achieve high separation efficiency, reduce acid-base consumption, and reduce acid-base consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The P507 organic phase is a sulfonated kerosene solution of the extractant P507, wherein the volume percentage of P507 is 30%, and the volume percentage of sulfonated kerosene is 70%.

[0027] The relevant rare earth ion concentrations in the light rare earth chloride aqueous solution are: La 25.0g / L, Ce 54.0g / L, Pr5.0g / L, Nd 17.0g / L, Sm 0.00050g / L.

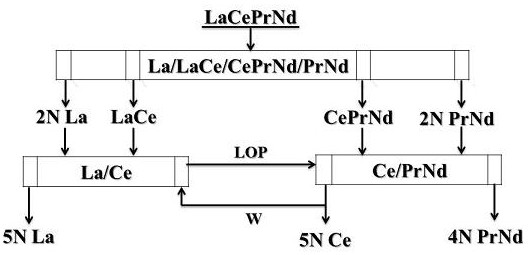

[0028] 1) La / LaCe / CePrNd / PrNd four-outlet fractional distillation extraction separation system

[0029] The 2N grade lanthanum saponified P507 organic phase is used as the extracted organic phase, the light rare earth chloride aqueous solution is used as the feed liquid, and 3.0mol / L HCl is used as the washing acid. The 2N-grade lanthanum saponification P507 organic phase enters the La / LaCe / CePrNd / PrNd four-outlet fractional distillation extraction and separation system from the first stage, and the light rare earth chloride solution enters the La / LaCe / CePrNd / PrNd four-outlet fractional distillation extraction and separati...

Embodiment 2

[0038] The P507 organic phase is a sulfonated kerosene solution of the extractant P507, wherein the volume percentage of P507 is 30%, and the volume percentage of sulfonated kerosene is 70%.

[0039] The relevant rare earth ion concentrations in the light rare earth chloride aqueous solution are: La 28.0g / L, Ce 51.0g / L, Pr6.0g / L, Nd 16.0g / L, Sm 0.00080g / L.

[0040] 1) La / LaCe / CePrNd / PrNd four-outlet fractional distillation extraction separation system

[0041] The 2N grade lanthanum saponified P507 organic phase is used as the extracted organic phase, the light rare earth chloride aqueous solution is used as the feed liquid, and 3.0mol / L HCl is used as the washing acid. The 2N-grade lanthanum saponification P507 organic phase enters the La / LaCe / CePrNd / PrNd four-outlet fractional distillation extraction and separation system from the first stage, and the light rare earth chloride solution enters the La / LaCe / CePrNd / PrNd four-outlet fractional distillation extraction and separati...

Embodiment 3

[0050] The P507 organic phase is a sulfonated kerosene solution of the extractant P507, wherein the volume percentage of P507 is 30%, and the volume percentage of sulfonated kerosene is 70%.

[0051] The relevant rare earth ion concentrations in the light rare earth chloride aqueous solution are: La 31.0g / L, Ce 48.0g / L, Pr7.0g / L, Nd 15.0g / L, Sm 0.0010g / L.

[0052] 1) La / LaCe / CePrNd / PrNd four-outlet fractional distillation extraction separation system

[0053] The 2N grade lanthanum saponified P507 organic phase is used as the extracted organic phase, the light rare earth chloride aqueous solution is used as the feed liquid, and 3.0mol / L HCl is used as the washing acid. The 2N-grade lanthanum saponification P507 organic phase enters the La / LaCe / CePrNd / PrNd four-outlet fractional distillation extraction and separation system from the first stage, and the light rare earth chloride solution enters the La / LaCe / CePrNd / PrNd four-outlet fractional distillation extraction and separatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com