Modified fluid loss agent

A water loss reducing agent and modification technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of affecting early strength and thickening time, poor thixotropic performance, etc., and achieve the goal of promoting hydration release Heat rate, increased sedimentation stability, strong drag reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

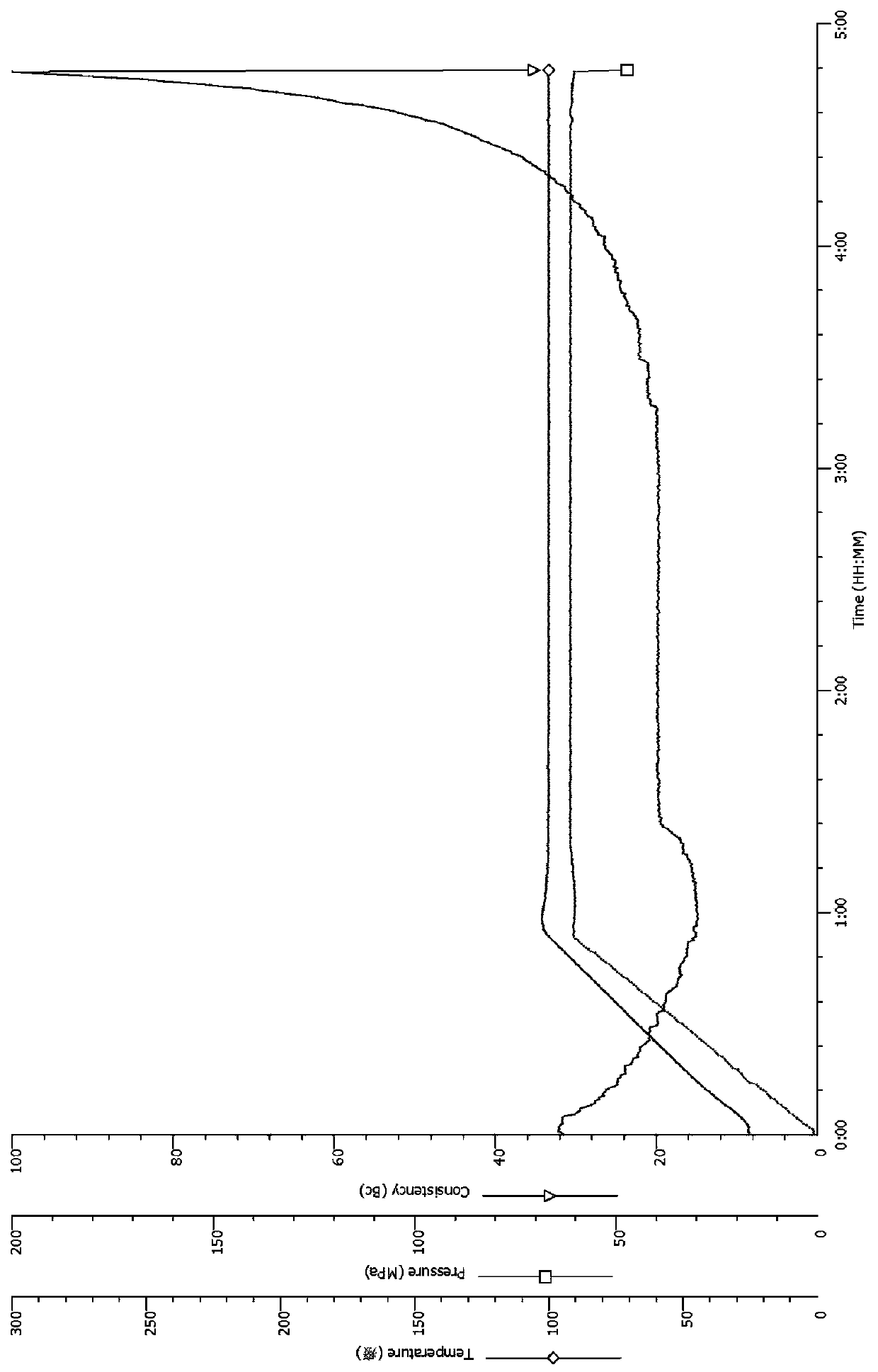

Image

Examples

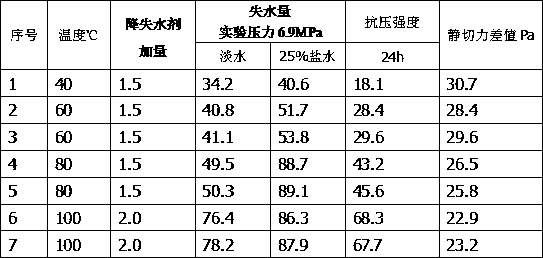

Embodiment 1

[0035] AMPS / AM copolymer 45%, bentonite 15%, superfine calcium carbonate 35%, aluminum sulfate 5%, test temperature 40 ℃, fluid loss reducing agent dosage 1.5%.

Embodiment 2

[0037] AMPS / AM copolymer 45%, bentonite 8%, superfine calcium carbonate 42%, aluminum sulfate 5%, test temperature 60 ℃, fluid loss reducing agent dosage 1.5%.

Embodiment 3

[0039] AMPS / AM copolymer 40%, bentonite 20%, superfine calcium carbonate 37%, aluminum sulfate 3%, test temperature 60 ℃, fluid loss reducing agent dosage 1.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com