Experimental device and experimental method for expansion performance of self-expansion sand control screen

A technology of sand control screen and expansion performance, which is applied in the direction of measurement device, material thermal expansion coefficient, suspension and porous material analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

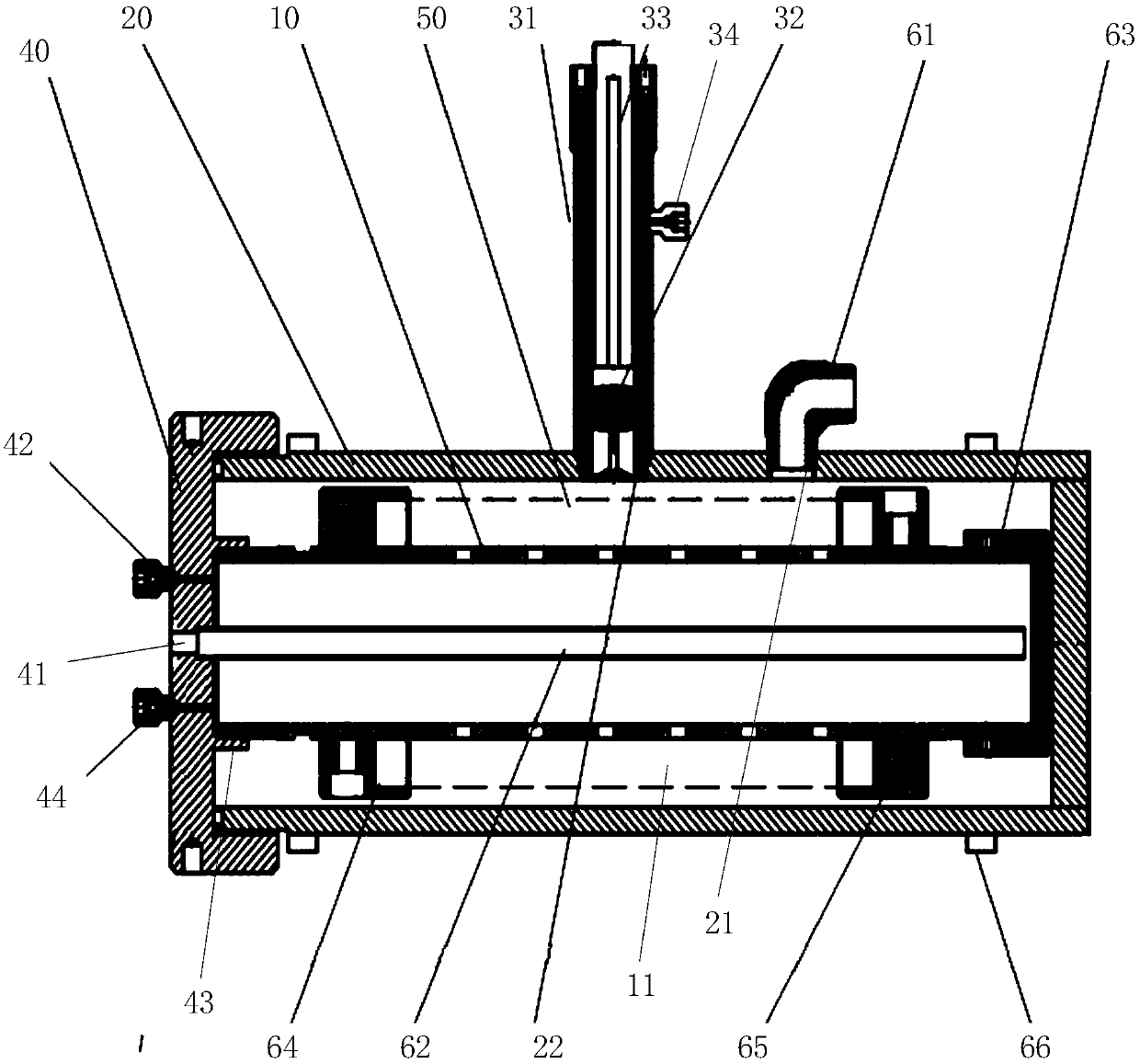

[0043] Such as figure 1 As shown, the present invention provides a self-expanding sand control screen expansion performance test device, including a cylinder 20, a self-expanding sand control screen positioned in the cylinder 20, a measuring rod 33 and a displacement sensor connected to the measuring rod 33 (in the figure not shown). in:

[0044] The self-expanding sand control screen includes a base pipe 10 and a self-expanding sleeve 50 sheathed on the base pipe 10 ; wherein, the outer wall of the base pipe 10 is provided with a plurality of through holes 11 , and the self-expanding sleeve 50 covers the through holes 11 .

[0045] The cylinder body 20 is used to simulate the well wall of an actual oil well, and a fluid inlet port 21 and a measurement port 22 are provided on the cylinder body 20 . Generally, the fluid inlet 21 and the measurement port 22 are arranged opposite to the self-expanding sleeve 50 . In order to allow the fluid to permeate the self-expanding sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com