Coating agent composition for agricultural film and modified thermoplastic polymer film for agriculture

A technology of thermoplastic polymers and compositions, applied in botanical equipment and methods, cellulose plastic material layered products, coatings, etc., can solve the problems of loss of dripping property, poor actual durability, etc., and maintain dripping property , good dripping, good dripping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

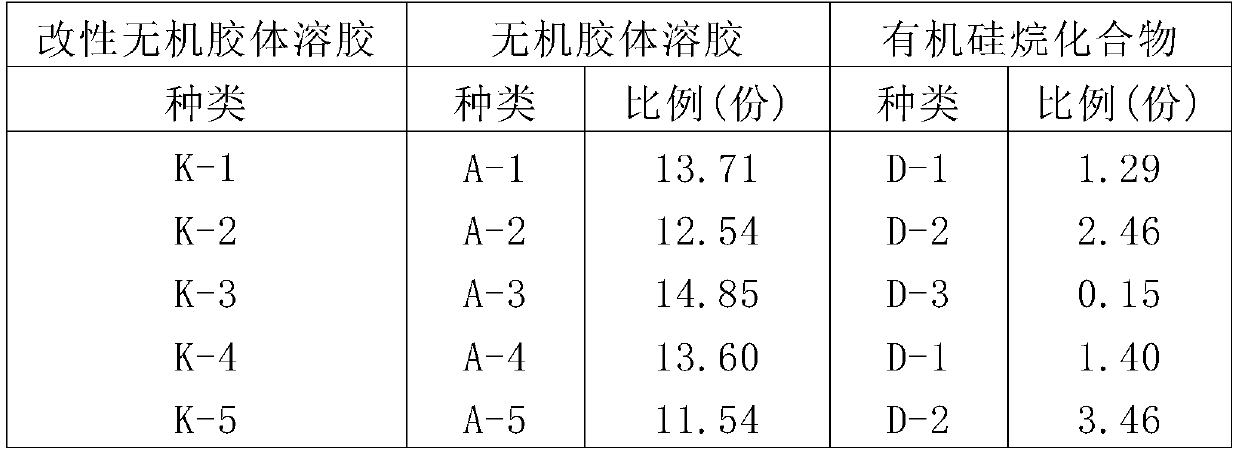

[0046] 26.5 parts of modified inorganic colloid sol (K-1) with a solid content concentration of 15%, 467 parts of water, 5 parts of cellulose derivatives (B-1), and a water-soluble crosslinking agent (C) with a solid content concentration of 70%. -1.4 parts were stirred with 0.01 part of polyether-modified silicone (S-1), and the coating agent composition (X-1) for agricultural films whose solid content concentration was 2% was obtained.

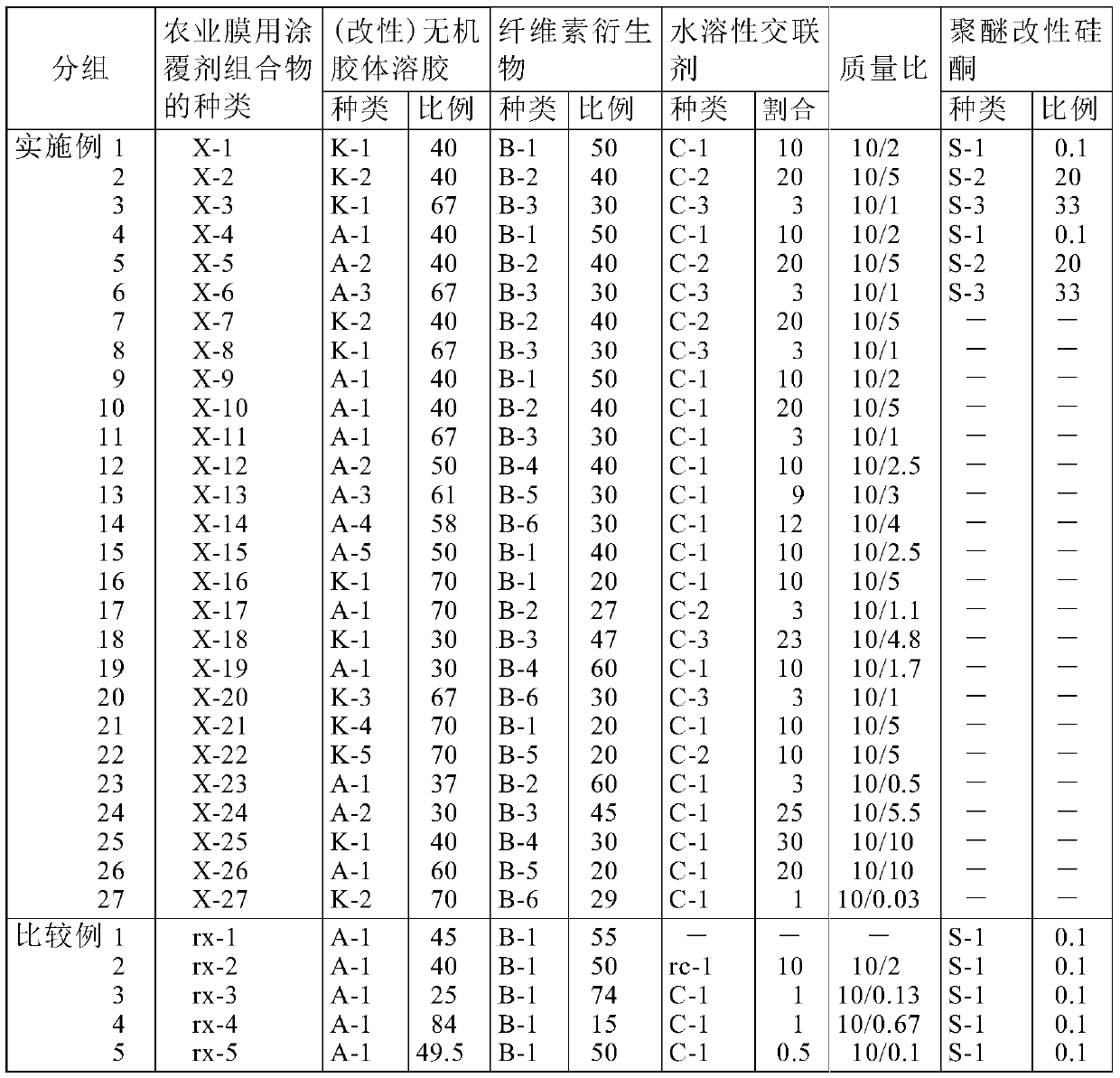

Embodiment 2~27 and comparative example 1~5

[0048] In the same manner as in the case of Example 1, the coating agent compositions (X-2) to (X-27) and (rx-1) to (rx- 5). Table 2 summarizes the content of the coating agent composition for agricultural film prepared by the above examples.

[0049] [Table 2]

[0050]

[0051] Table 2,

[0052] (Modified) ratio of inorganic colloidal sol, cellulose derivative and water-soluble crosslinking agent: parts by mass based on solid content

[0053] Mass ratio: cellulose derivative / water-soluble crosslinking agent

[0054] Ratio of polyether-modified silicone: parts by mass based on 100 parts by mass in terms of solid content of (modified) inorganic colloidal sol

[0055] K-1~K-5: Modified inorganic colloidal sols described in Table 1

[0056] A-1 to A-5: Inorganic colloidal sols described in Table 1

[0057] B-1: Hydroxypropylmethylcellulose (the viscosity of 2% aqueous solution at 20°C is 50mPa·s)

[0058] B-2: Hydroxypropylmethylcellulose (the viscosity of 2% aqueous so...

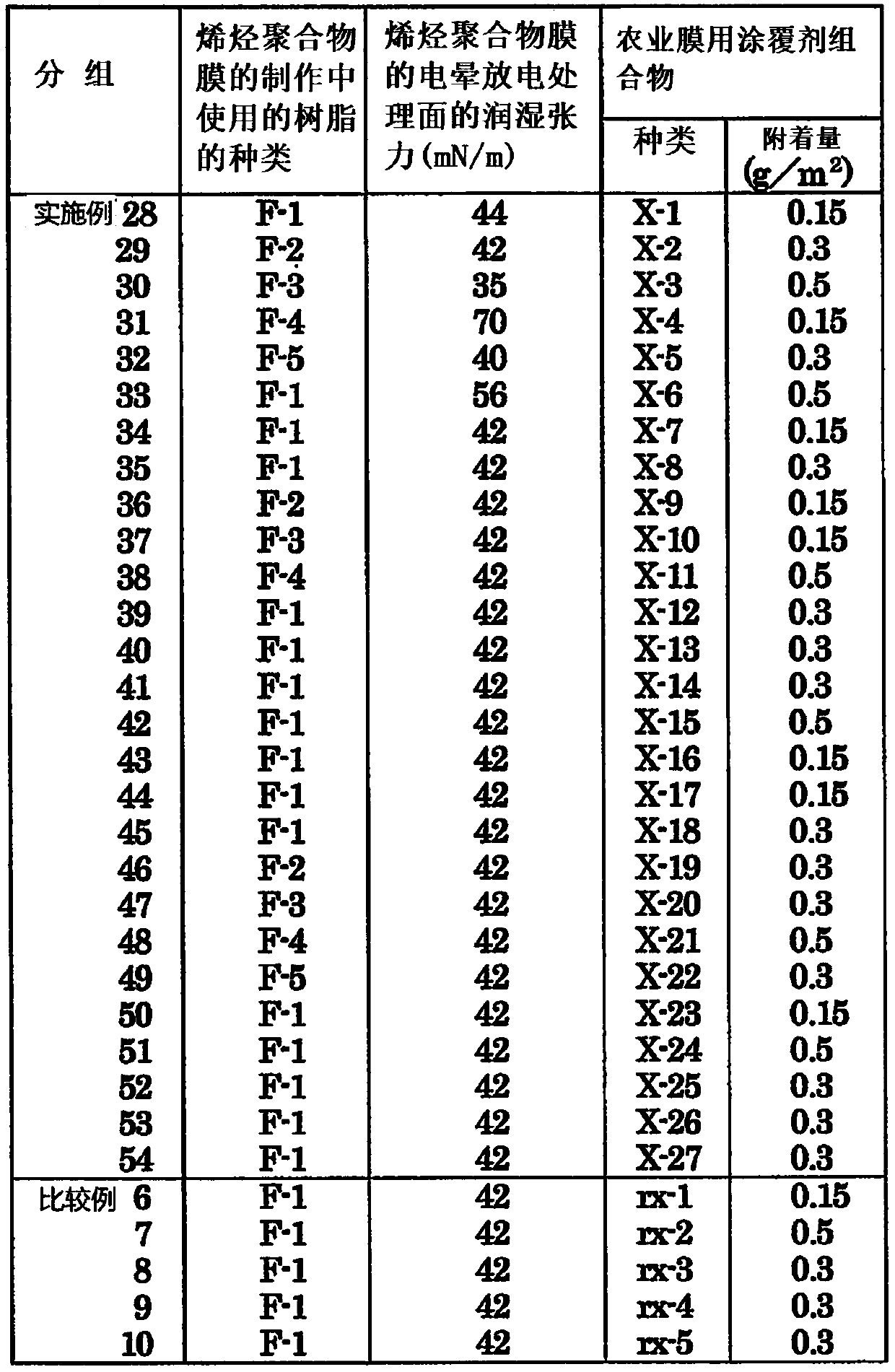

Embodiment 28

[0079] The ethylene·1-butene copolymer (ethylene copolymerization ratio 95%, density 0.920g / cm 3 , MFR2.1g / 10 minutes) is supplied to an inflation molding machine equipped with a die head with a diameter of 75mm and a die lip gap of 3mm, and the inflation molding is carried out under the conditions of resin extrusion temperature 200°C and BUR=1.8, and a thickness of 150μm is produced. olefin polymer film. Next, the olefin polymer film is subjected to corona treatment discharge, so that the wetting tension of the corona discharge treatment surface is 42mN / m, after that, the agricultural film coating agent composition (X-1) prepared in the test group 2 is applied 0.3g / m2 based on solid content 2 Apply to the corona discharge treated surface by gravure coating method, and stay in a hot air drying oven whose temperature is adjusted to 70° C. for 1 minute to obtain a modified thermoplastic polymer film for agriculture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com