A thermal insulation anti-aging anti-fog agricultural shed film and its preparation method

An anti-aging, shed film technology, applied in the field of agricultural shed film, can solve the problems of poor adhesion between the coating and the polyethylene surface, short duration of the shed film drip and fog elimination, loss of drip and fog elimination function, etc. The effect of increasing production is obvious, it is beneficial to photosynthesis, and the effect of improving dripping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

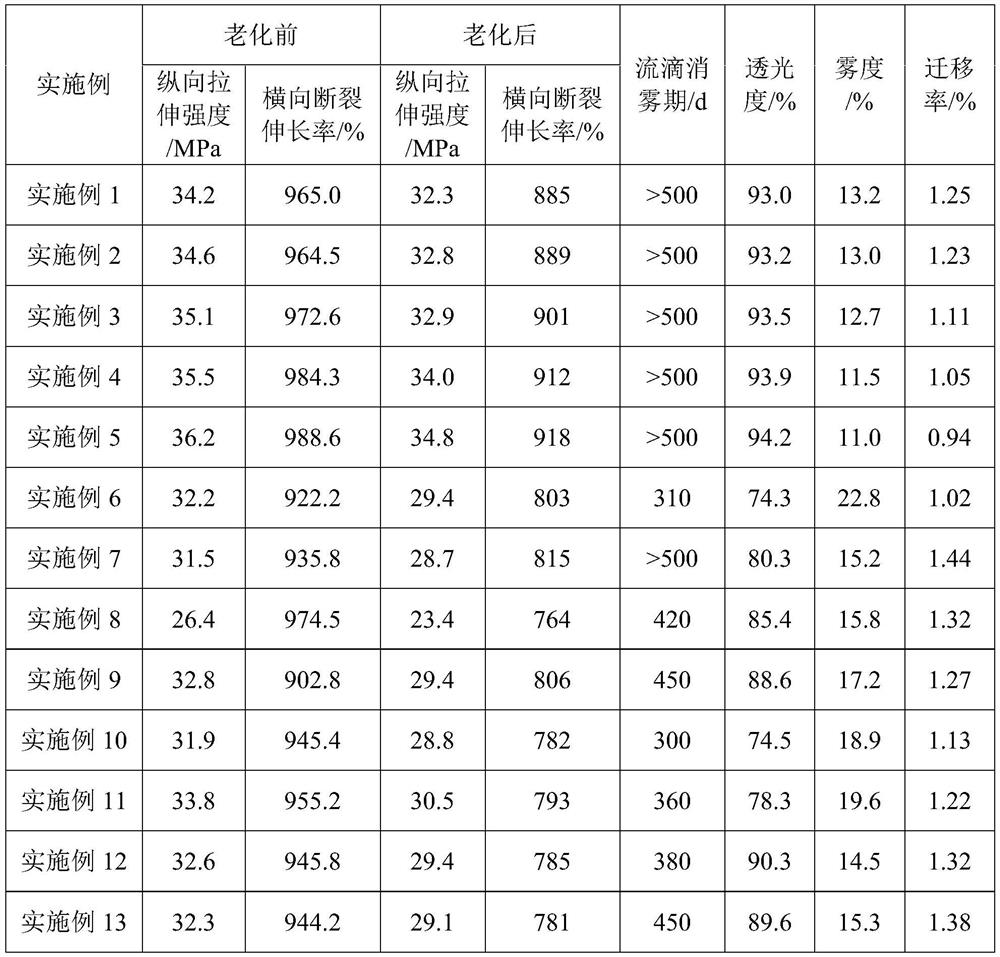

Examples

preparation example Construction

[0144] The second aspect of the present invention provides the preparation method of the anti-ultraviolet and anti-aging masterbatch, comprising the following steps: adding the LDPE, hindered amine light stabilizer, ultraviolet absorber, composite antioxidant, functional auxiliary agent, slippery Put the agent into a high-speed mixer and mix for 10-15 minutes, then transfer to a twin-screw extruder for melt extrusion, the extrusion temperature is 150-200°C, and the anti-ultraviolet and anti-aging masterbatch is obtained after air cooling.

[0145] The third aspect of the present invention provides the preparation method of the thermal insulation masterbatch, comprising the following steps: putting the LDPE, transparent thermal insulation agent, basic magnesium carbonate, and PPA auxiliary agent into a high-speed mixer and mixing for 10 to 15 minutes, and then transferring To the twin-screw extruder for melt extrusion, the extrusion temperature is 150-200° C., and the heat-insul...

Embodiment 1

[0150] Embodiment 1 provides a heat preservation and anti-aging anti-fog agricultural shed film, said agricultural shed film includes a base film layer and a coating layer, the base film layer consists of an inner layer, an inner two layer, a middle layer, an outer two layer, an outer layer Layers, and each layer is stacked from the inner layer to the outside; wherein, by weight, the base film layer includes: 12 parts of the inner layer, 10 parts of the inner two layers, 18 parts of the middle layer, and the outer two layers 18 copies, 25 copies for the outer layer.

[0151] In parts by weight, the inner layer of the present invention includes: 40 parts of mLLDPE, 20 parts of LDPE, and 5 parts of anti-ultraviolet and anti-aging masterbatch.

[0152] The sources of each component of the inner layer are as follows:

[0153] The mLLDPE of the inner layer is purchased from Exxon Mobil, and the product number is 1327CA;

[0154] The LDPE of the inner layer is purchased from Exx...

Embodiment 2

[0202] Embodiment 2 provides a heat preservation and anti-aging anti-fog agricultural shed film, said agricultural shed film comprises a base film layer and a coating layer, the base film layer consists of an inner layer, an inner two layer, a middle layer, an outer two layer, an outer layer Layers, and each layer is stacked from the inner layer to the outside; wherein, by weight, the base film layer includes: 12 parts of the inner layer, 10 parts of the inner two layers, 18 parts of the middle layer, and the outer two layers 18 copies, 25 copies for the outer layer.

[0203] In parts by weight, the inner layer of the present invention includes: 70 parts of mLLDPE, 30 parts of LDPE, and 10 parts of anti-ultraviolet and anti-aging masterbatch.

[0204] The sources of each component of the inner layer are as follows:

[0205] The mLLDPE of the inner layer is purchased from Exxon Mobil, and the product number is 1327CA;

[0206] The LDPE of the inner layer is purchased from E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com