Thermoplastic polymer film coating composition and method for producing the same, modified thermoplastic polymer film and method for producing the same

A technology of thermoplastic polymers and compositions, applied in botany equipment and methods, chemical instruments and methods, coatings, etc., can solve problems such as insufficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] An inorganic cationic colloid sol was prepared by mixing 331.3 parts of water and 740.7 parts of a cationic alumina sol (X1-1) (solid content: 13.5%). 8 parts of the silanol-forming organosilane compound (Y-1) were mixed with this inorganic cationic colloidal sol to prepare a mixed liquid having a solid content concentration of 10%, and stirred at 50° C. for 5 hours for the silanol-forming organosilane compound (Y-1). -1) A hydrolysis treatment is performed, and the generated silanol compound is further polycondensed to obtain a modified inorganic cationic colloidal sol (A-1). The modified inorganic cationic colloidal sol (A-1) is obtained by adhering a polycondensate of a silanol compound to the solid content particles of the above-mentioned inorganic cationic colloidal sol. Next, 8900 parts of water, 30 parts of polyether-modified silicone (B-1), polyoxyalkylene derivative ( 10 parts of C-1) and 60 parts of ethylene oxide-propylene oxide block polymer (D-1) were stir...

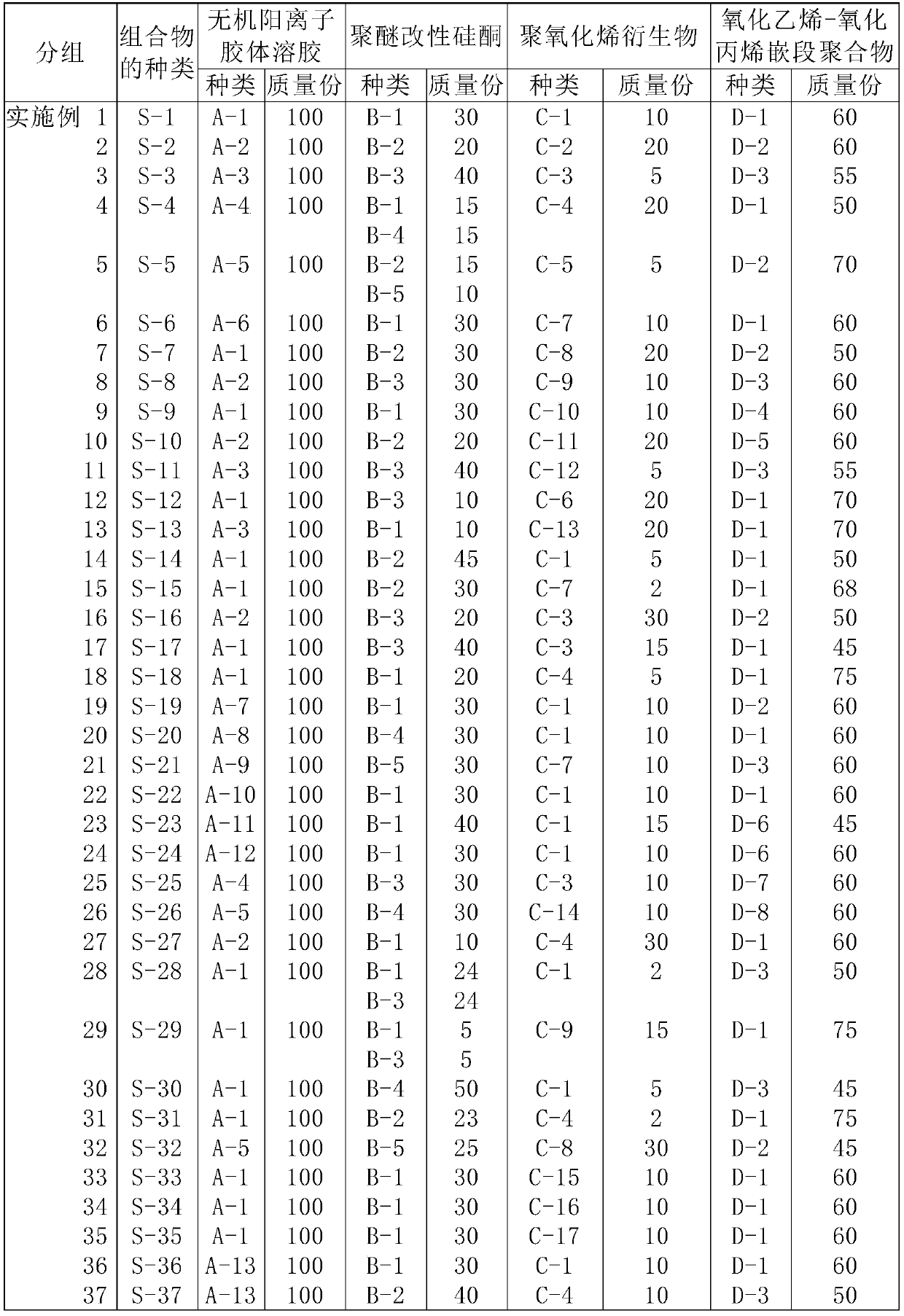

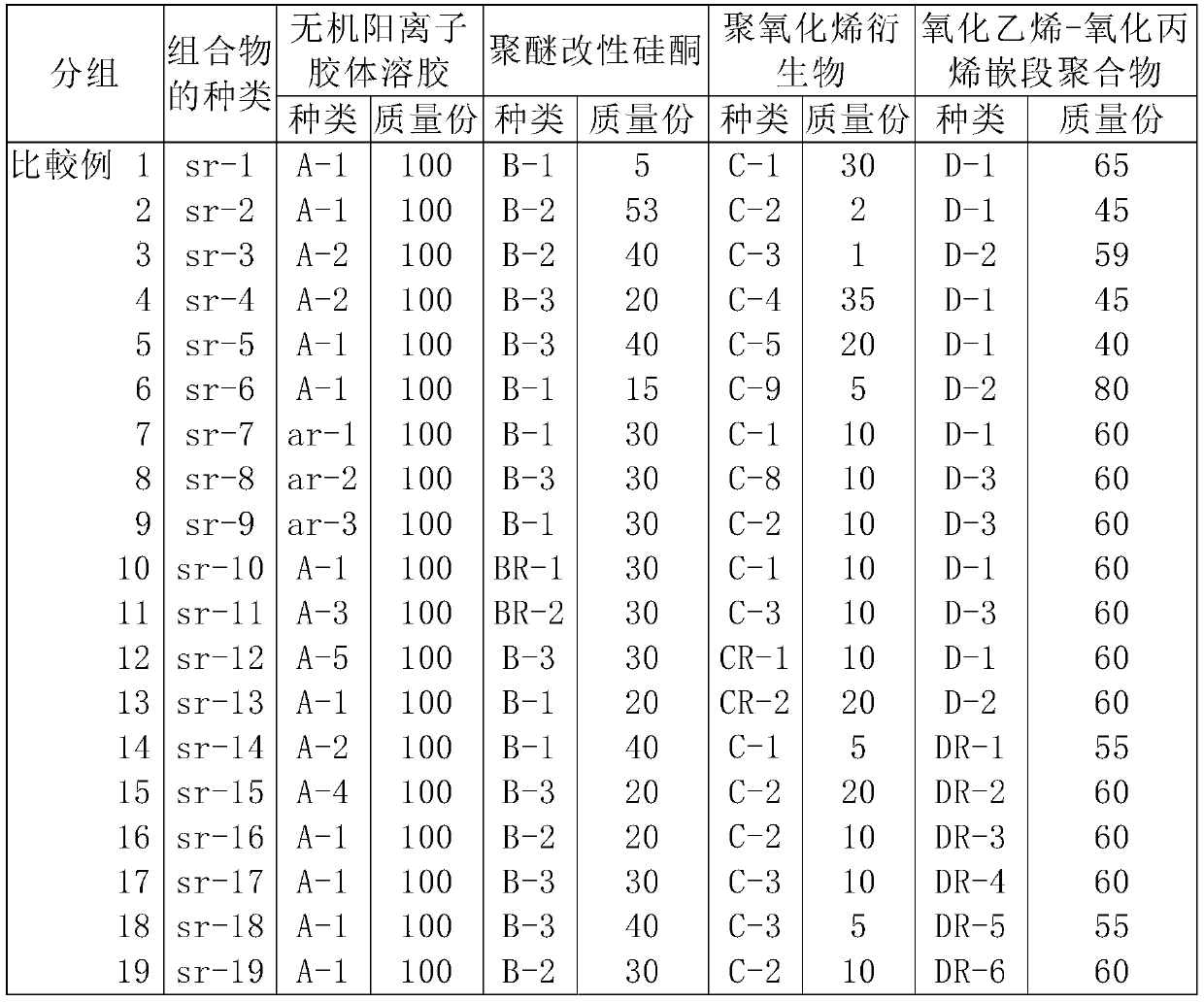

Embodiment 2~37 and comparative example 1~19

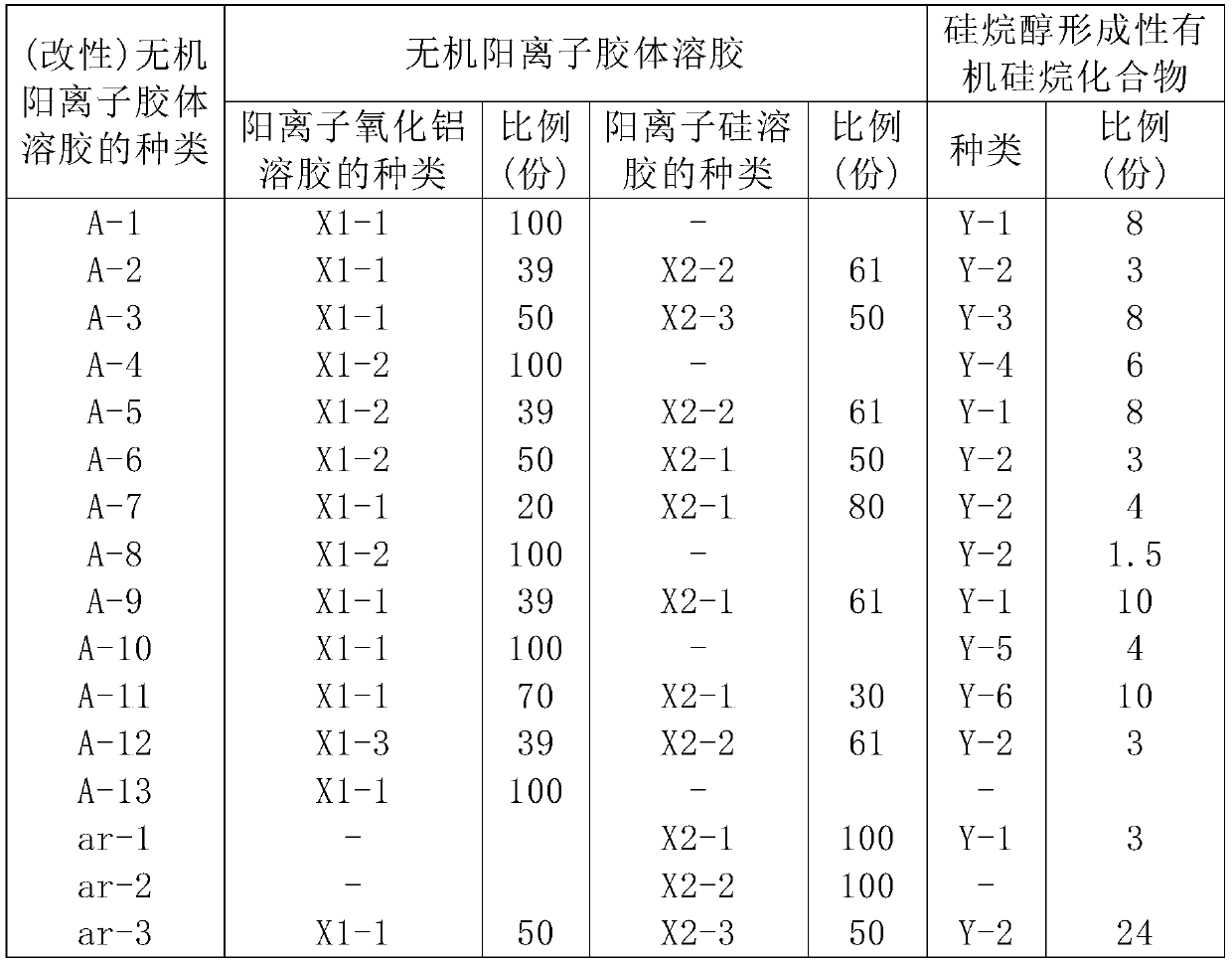

[0056] Prepare (modified) inorganic cationic colloidal sols (A-2)~(A-13) and (ar-1)~(ar-3) in the same manner as in the case of Example 1, and further obtain Examples 2~37 and comparison Compositions (S-2) to (S-37) and (sr-1) to (sr-19) for thermoplastic polymer film coating of Examples 1 to 19. The content of the (modified) inorganic cationic colloid sol prepared in the above examples is summarized in Table 1, and the content of the thermoplastic polymer film coating composition obtained by the above examples is summarized in Table 2 and Table 3.

[0057] 【Table 1】

[0058]

[0059] in FIG. 1,

[0060] X1-1: feathery crystalline alumina sol with a particle size of 7-15nm

[0061] X1-2: Fibrous crystalline alumina sol with a secondary dispersion diameter of 100-150nm

[0062] X1-3: Tabular crystalline alumina sol with a particle size of 15-30nm

[0063] X2-1: Alumina-modified silica sol with a particle size of 10-15nm

[0064] X2-2: Alumina-modified silica sol with a ...

Embodiment 38

[0120] The ethylene·1-butene copolymer (ethylene copolymerization ratio 96%, density 0.930g / cm 3 , MFR1.0g / 10 minutes) were given to the inflation molding machine equipped with a die head with a diameter of 75mm and a die lip gap of 3mm, and inflation molding was carried out under the conditions of resin extrusion temperature 200°C and BUR=1.8, making An olefin polymer film with a thickness of 150 μm was produced. Next, corona treatment discharge was performed on the olefin polymer film, and after the wetting tension of the corona discharge treatment surface was set to 44 mN / m, the thermoplastic polymer film prepared in test group 1 was coated by the gravure printing method. Composition (S-1) is 0.3 g / m in terms of solid content 2 It was applied to the corona discharge-treated surface, and was left in a hot-air drying oven adjusted to 70° C. for 1 minute to obtain the modified thermoplastic polymer film of each example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com