A kind of aramid fiber skin-paper honeycomb sandwich shell structure and its preparation method

A paper honeycomb and shell structure technology, applied in chemical instruments and methods, paper/cardboard layered products, lamination, etc., can solve problems such as inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

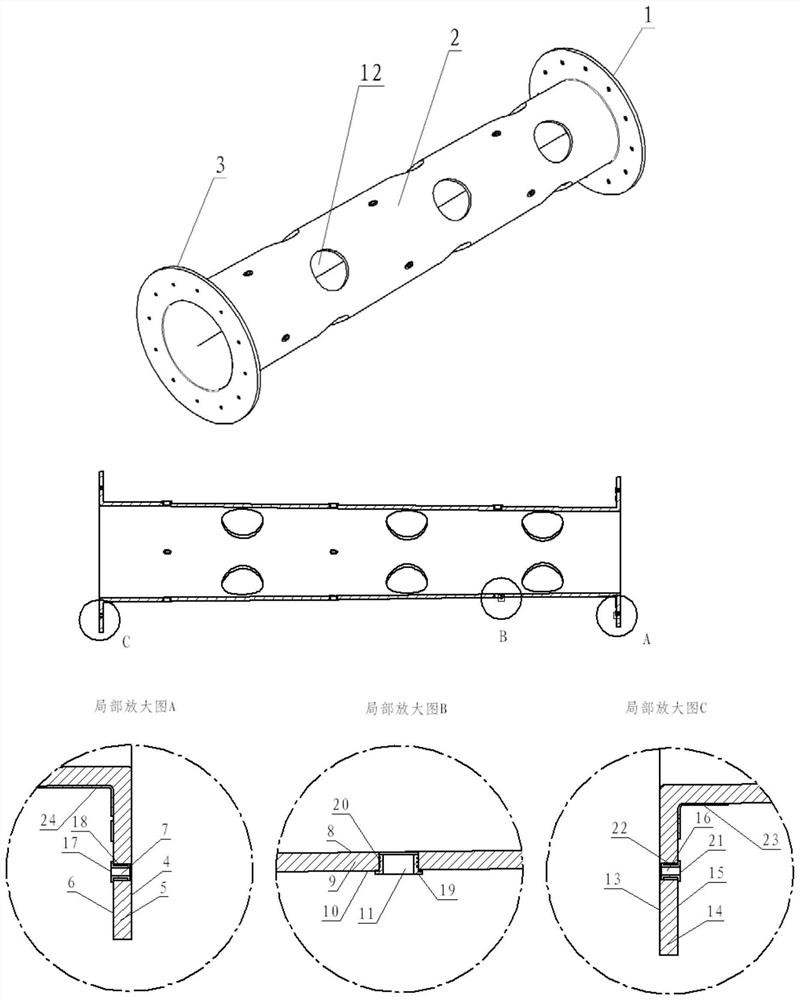

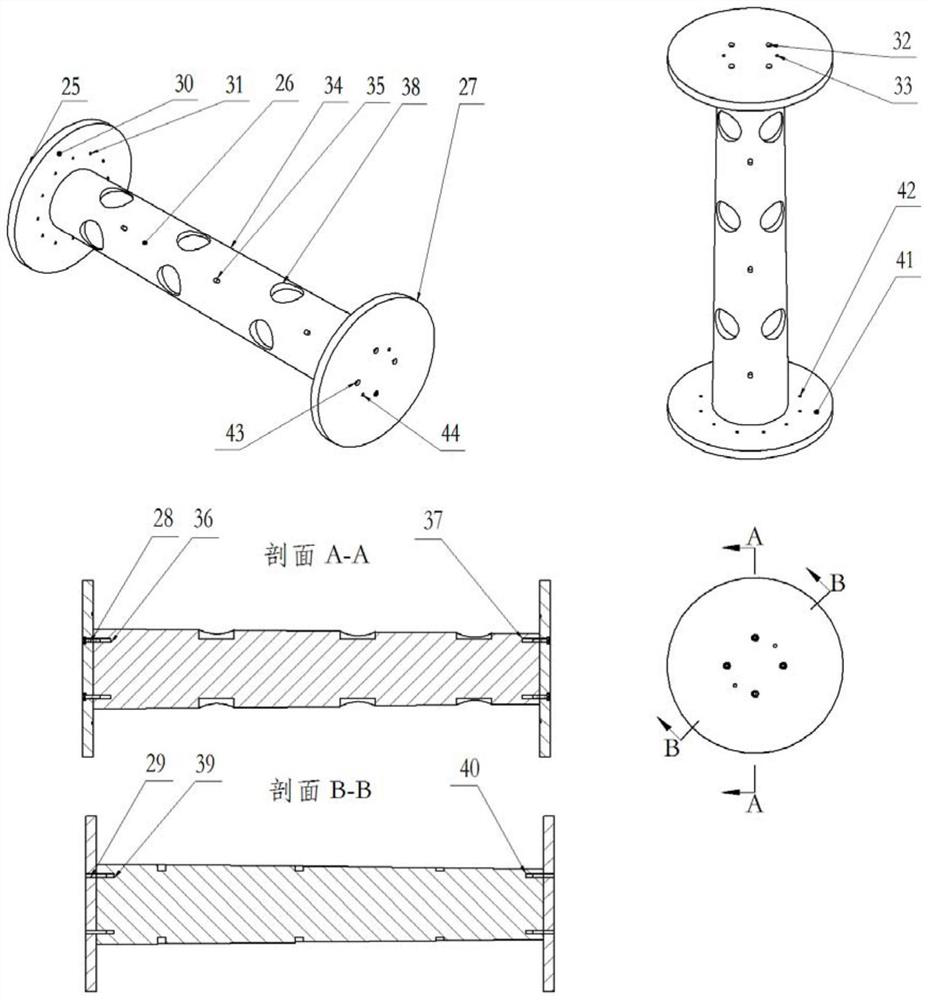

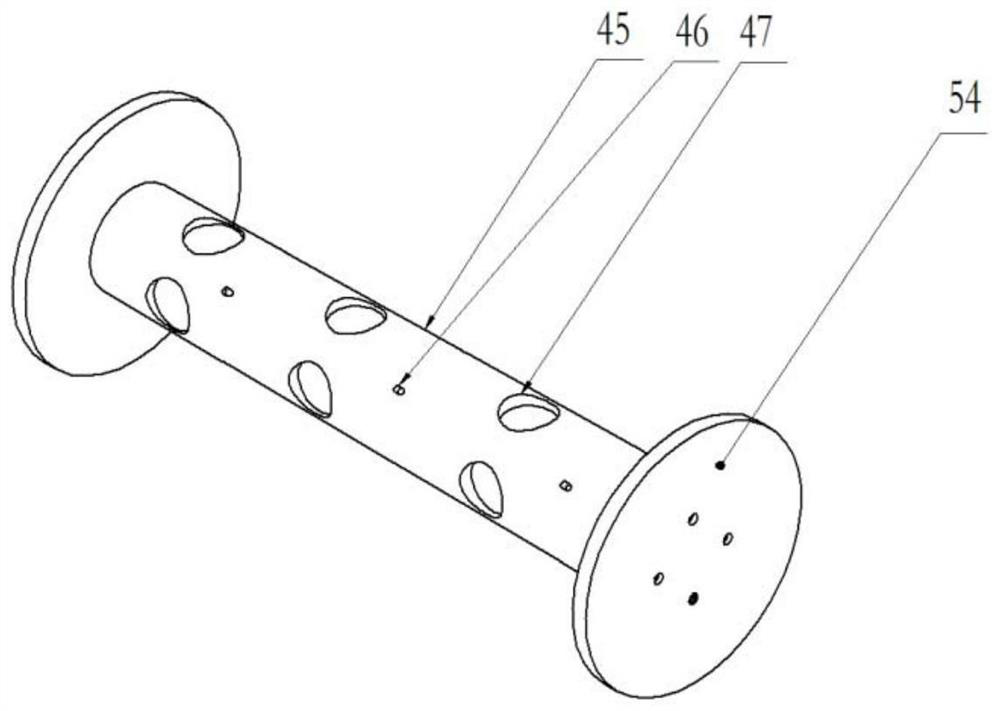

[0061] A kind of aramid fiber skin - paper honeycomb sandwich shell structure such as figure 1 As shown, the structure includes an upper flange 1, a cylinder body 2 and a lower flange 3; the upper flange 1 includes an aramid outer skin A4, a paper honeycomb sandwich core A5, an aramid inner skin A6 and a connecting joint A7; the cylinder body 2 includes aramid inner skin B8, paper honeycomb sandwich B9, aramid outer skin B10, connecting joint B11 and lightening hole 12; lower flange 3 includes aramid outer skin C13, paper honeycomb sandwich C14, aramid inner Skin C15 and connecting joint C16;

[0062] Between the aramid outer skin A4 and the aramid inner skin A6 of the upper flange 1 is a paper honeycomb sandwich A5, and the connecting joint A7 includes two parts: a flange A17 and a connecting column A18, and the flange A17 is located on the aramid On the inner skin A6, the connecting column A18 is embedded in the paper honeycomb sandwich core A5;

[0063] Between the aramid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| flat compressive strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com