Pull screw reinforcing mechanism and reinforcing mechanism construction method

A technology of anti-tension screw and construction method, which is applied in the direction of building construction, on-site preparation of building components, and connection parts of formwork/formwork/work frame, etc., which can solve the problems of weak reinforcement and reduce mechanical damage. Incidence rate, guaranteed repeated disassembly usage rate, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

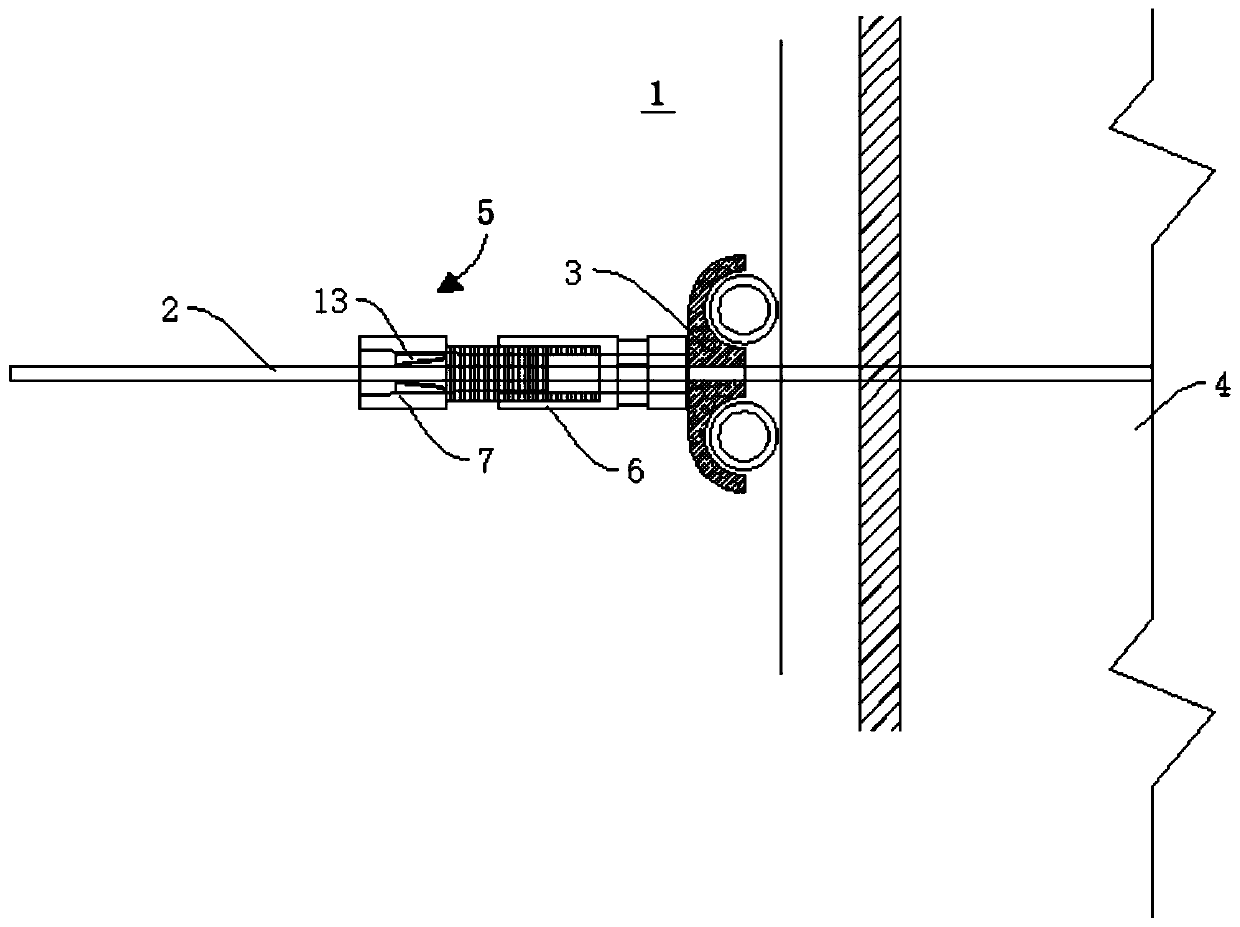

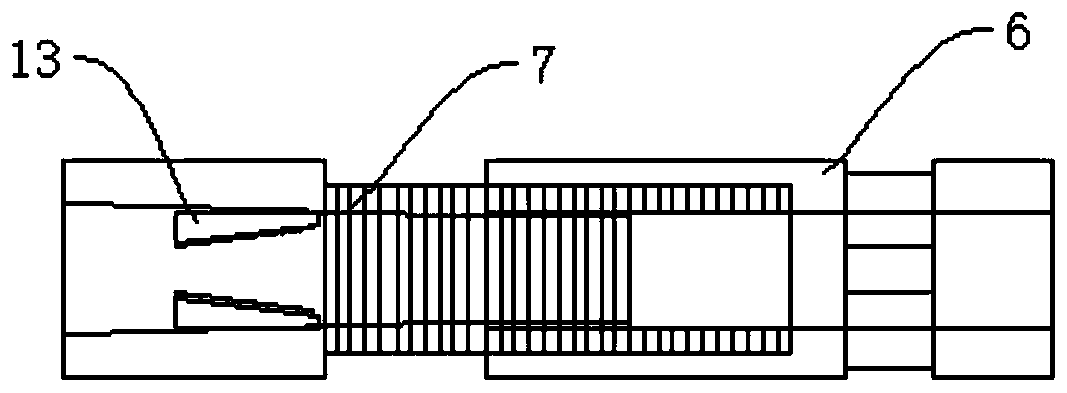

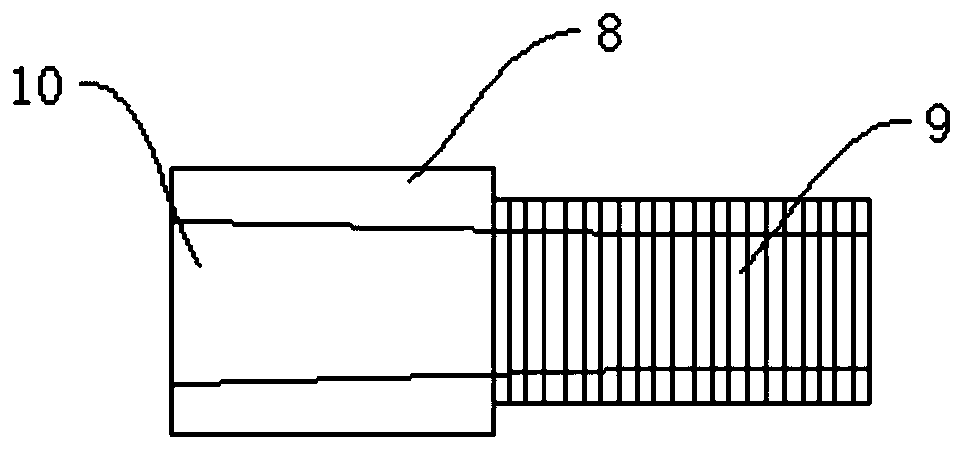

[0039] Please refer to figure 1 , with reference to Figure 2 to Figure 5 , the application provides a double-pull screw reinforcement mechanism 1, which mainly includes a double-pull screw 2, a mountain-shaped card 3 and an assembly 5, and the assembly 5 includes a U-shaped sleeve 6 and a T-shaped sleeve 7; One end of the screw 2 passes through the wall 4, the mountain-shaped card 3, the U-shaped sleeve 6 and the T-shaped sleeve 7 in turn; the mountain-shaped card 3 is installed on one end of the pull screw 2 passing through the wall 4, and tighten Stick to the outside of the wall 4; one end of the U-shaped sleeve 6 tightens the mountain-shaped card 3, and the other end is socketed on the T-shaped end of the T-shaped sleeve 7 through a thread; the T-shaped sleeve 7 is far away from the U-shaped sleeve One end of 6 is provided with a conical hole, and a clamp 13 for clamping the pull screw 2 is installed in the conical hole; the mountain-shaped card 3 is tightened by rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com