Novel pretreatment film bioreactor and application method thereof

A membrane bioreactor, pretreatment technology, applied in chemical instruments and methods, filtration treatment, special treatment targets, etc., to achieve the effects of reducing usage, improving stability, and improving the quality of produced water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A decentralized integrated sewage treatment and reuse device based on pretreatment membrane bioreactor photocatalytic oxidation technology

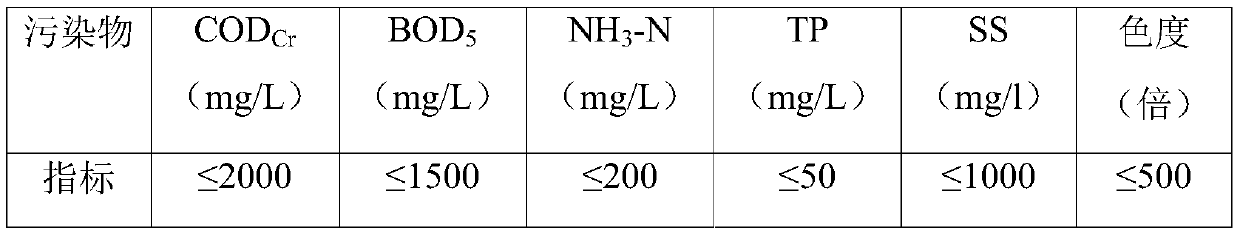

[0051] (1) Introduce rural domestic sewage into the pretreatment area, where the raw water indicators are as follows:

[0052]

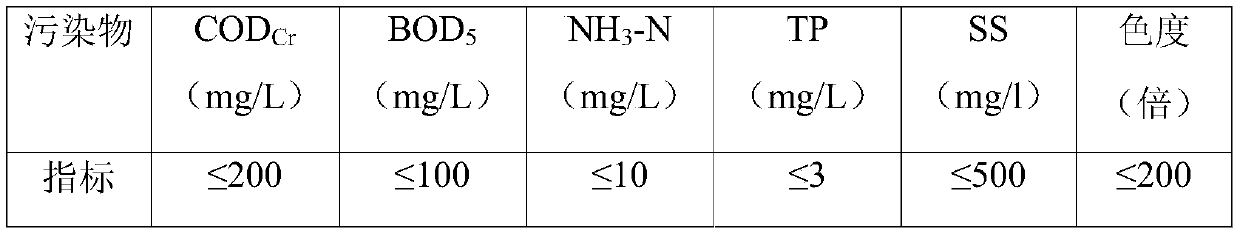

[0053] Among them, the anoxic / aerobic process (referred to as A / O process) is adopted in the pretreatment area. After the pretreatment process, the water quality indicators are as follows:

[0054]

[0055] (2) The water produced in the pretreatment area enters the MBR area, and the MBR water production indicators are as follows:

[0056]

[0057]

[0058] The MBR membrane adopts a submerged hollow fiber membrane with a membrane separation pore size of 0.4 μm and a membrane flux of 15LMH.

[0059] (3) The water produced in the MBR area enters the MBR water production area, a small amount is used for membrane system maintenance, and most of the overflow enters the photocatalytic oxidation area...

Embodiment 2

[0063] A decentralized integrated sewage treatment and reuse device based on pretreatment membrane bioreactor photocatalytic oxidation technology

[0064] (1) Introduce the sewage from the soybean product processing plant into the pretreatment area through the septic tank, and the raw water indicators are as follows:

[0065]

[0066] Among them, the coagulation sedimentation / anoxic / aerobic process is adopted in the pretreatment area. After the pretreatment process, the water quality indicators are as follows:

[0067]

[0068] (2) The water produced in the pretreatment area enters the MBR area, and the MBR water production indicators are as follows:

[0069]

[0070] The MBR membrane adopts a submerged hollow fiber membrane with a membrane separation pore size of 0.4 μm and a membrane flux of 12LMH.

[0071] (3) The water produced in the MBR area enters the MBR water production area, a small amount is used for membrane system maintenance, and most of the overflow en...

Embodiment 3

[0077] A decentralized integrated sewage treatment and reuse device based on pretreatment membrane bioreactor photocatalytic oxidation technology

[0078] (1) Introduce the sewage from the community into the pretreatment area through the septic tank, and the raw water indicators are as follows:

[0079]

[0080] Among them, the anoxic / aerobic process is adopted in the pretreatment area. After the pretreatment process, the water quality indicators are as follows:

[0081]

[0082] (2) The water produced in the pretreatment area enters the MBR system, and the MBR water production indicators are as follows:

[0083]

[0084] The MBR membrane adopts a submerged hollow fiber membrane with a membrane separation pore size of 0.4 μm and a membrane flux of 12LMH.

[0085] (3) The water produced in the MBR area enters the MBR water production tank, a small amount is used for membrane system maintenance, and most of the overflow enters the photocatalytic oxidation area for oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com