Antenna preparation method using vacuum plating combined with laser process and 5G antenna

A laser process and vacuum plating technology, applied in the field of 5G antennas, can solve problems such as difficult high-precision production of 5G antennas, inability to play antenna performance, antenna resonance frequency deviation, etc., to achieve flexible and wide range of use, meet the requirements of transmitting and receiving performance, The effect of overcoming the deterioration of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

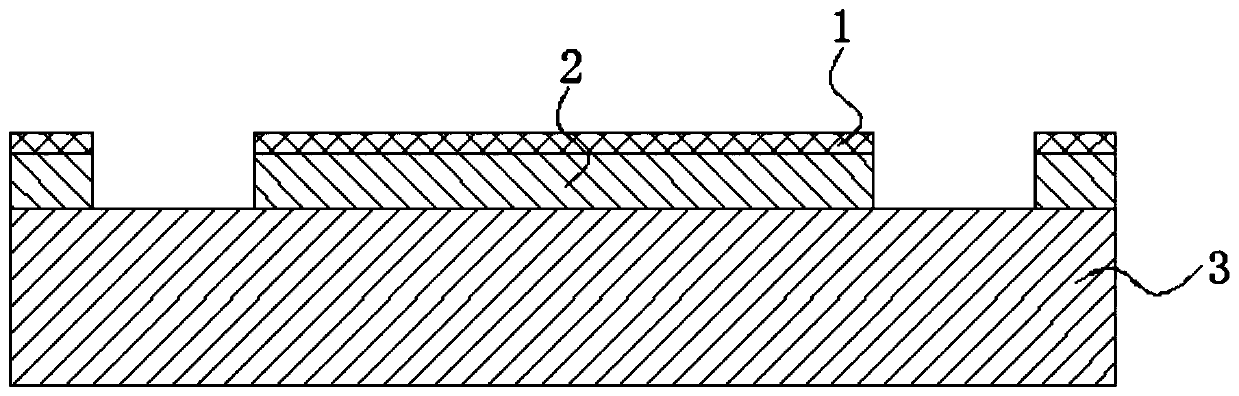

[0032] refer to figure 1 , a method for preparing an antenna utilizing vacuum plating combined with a laser process, comprising the following steps:

[0033] Substrate surface cleaning treatment:

[0034] First, clean the surface of the plastic substrate 3 to keep the surface of the plastic substrate 3 clean, thereby improving the adhesion and smoothness of the metal coating. First, put the plastic substrate 3 into an alkaline solution at a temperature of 50°C for ultrasonic cleaning. Degrease and degrease, the time is 5 minutes, wash with pure water after completion, then put in 3% dilute sulfuric acid solution to neutralize the residual lye, time 5 seconds, finally rinse with pure water and dry;

[0035] S1: Metallization treatment on the surface of plastic substrate:

[0036] After the cleaning is completed, put the plastic substrate 3 into the vacuum ion coating machine of the pure copper target, seal the vacuum chamber, start the vacuum pump to pump the air pressure of ...

Embodiment 2

[0042] refer to figure 2 , a method for preparing an antenna utilizing vacuum plating combined with a laser process, comprising the following steps:

[0043] Substrate surface cleaning treatment:

[0044] First, clean the surface of the 2.5D or 3D glass back cover substrate 3' to keep the surface of the glass back cover clean, thereby improving the adhesion and smoothness of the metal coating. First, put the glass back cover into an alkaline solution at a temperature of 70°C Ultrasonic cleaning is carried out to degrease and degrease for 8 minutes. After completion, wash with pure water, then put it into 5% dilute sulfuric acid solution to neutralize the residual lye for 8 seconds, and finally rinse with pure water and dry ;

[0045] S1: Surface metallization of glass back cover substrate:

[0046] After the cleaning is completed, put the glass back cover substrate 3' into the magnetron sputtering coating machine of the pure copper target, seal the vacuum chamber, and start ...

Embodiment 3

[0052] Based on the foregoing solution, the substrate may also be a ceramic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com