Energy-saving environment-friendly copper-containing sludge smelting method

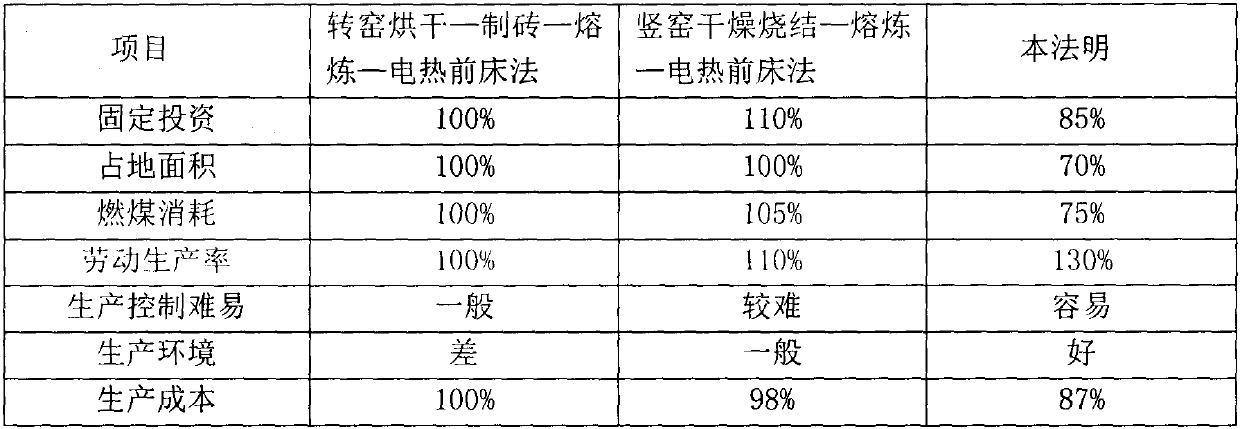

A smelting method, an energy-saving and environment-friendly technology, which is applied in the field of smelting copper-containing sludge, and can solve the problems of high technical requirements for drying and sintering operations in shaft kilns, large floor space and fixed investment, and unutilized waste heat from smelting furnace flue gas. , to achieve the effects of thorough flue gas environmental protection treatment, low smelting production cost, and remarkable environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

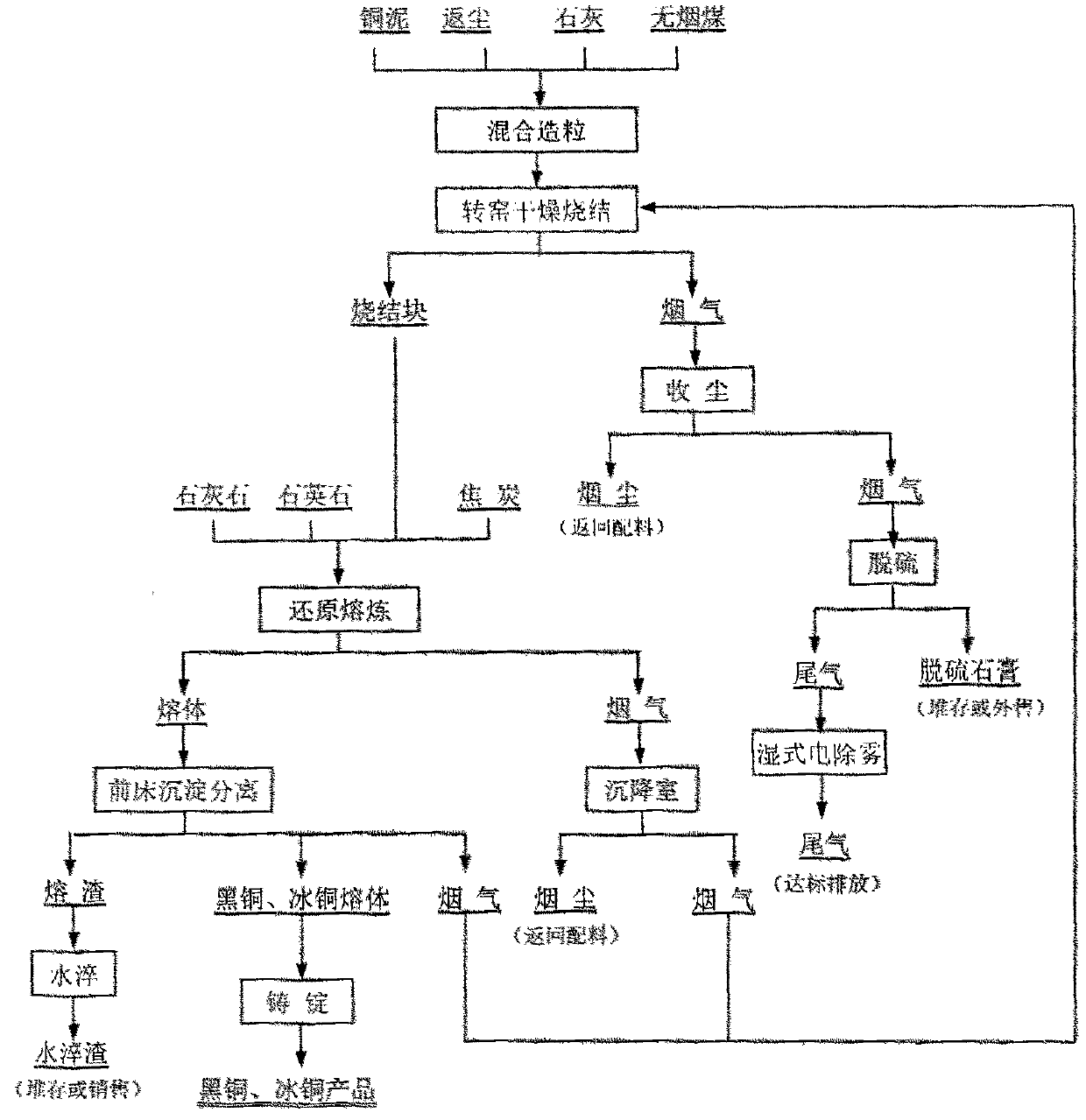

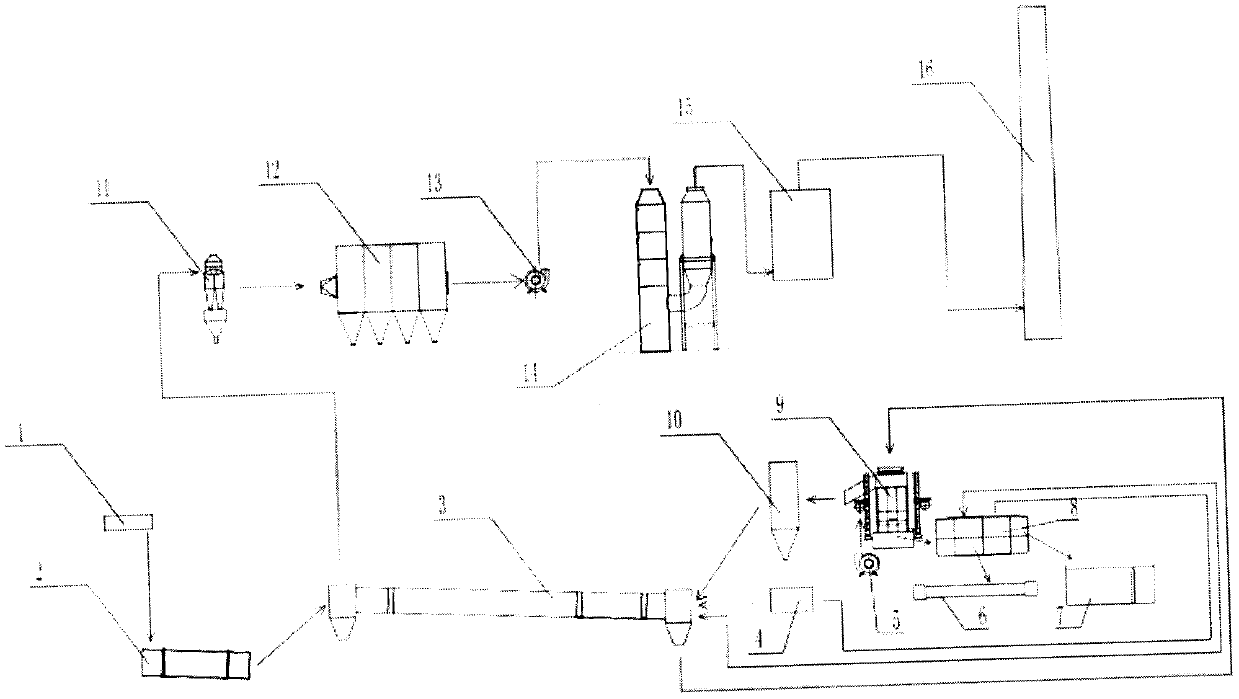

[0019] Such as figure 1 , figure 2 Shown, the smelting method of a kind of energy-saving and environment-friendly copper-containing sludge of the present invention comprises the following steps:

[0020] 1. Mixing and granulation: Copper-containing sludge and returned dust are mixed with lime and pulverized coal at a ratio of 1:0.04:0.05. After being homogenized, they are transported to the upper silo by means of a grab bucket, and then transported to the double silo by a belt. The shaft mixer 1 performs stirring and mixing, and after mixing, it enters the drum granulator 2, and the drum granulator 2 controls and sprays granulation water for uniform granulation.

[0021] 2. Rotary kiln drying and sintering: the granulated material is transported to the lower silo at the kiln end of the rotary kiln 3 by belt, and enters the rotary kiln 3 from the lower silo, and the granules are moved to the direction of the kiln head by the horizontal inclination and rotation of the rotary k...

Embodiment 2

[0026] 1. Mixing and granulation: Copper-containing sludge and returned dust are mixed with lime and pulverized coal at a ratio of 1:0.05:0.07. After being homogenized, they are transported to the upper silo by means of a grab bucket, and then transported to the double silo by a belt. The shaft mixer 1 performs stirring and mixing, and after mixing, it enters the drum granulator 2, and the drum granulator 2 controls and sprays granulation water for uniform granulation.

[0027] 2. Rotary kiln drying and sintering: the granulated material is transported to the lower silo at the kiln end of the rotary kiln 3 by belt, and enters the rotary kiln 3 from the lower silo, and the granules are moved to the direction of the kiln head by the horizontal inclination and rotation of the rotary kiln 3 Movement, reverse contact with high-temperature flue gas, the temperature of the pellets continues to rise, so that free water and crystal water in the pellets are removed and hydroxides are dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com