Thermal-insulation cotton prepared from iron making hot slag and waste incineration fly ash, and preparation method thereof

A technology for waste incineration fly ash and thermal insulation cotton, which is applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of inability to utilize hot slag sensible heat, deterioration of working environment, slag accumulation atmosphere, water and soil pollution, etc. Realize the effect of harmless and resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

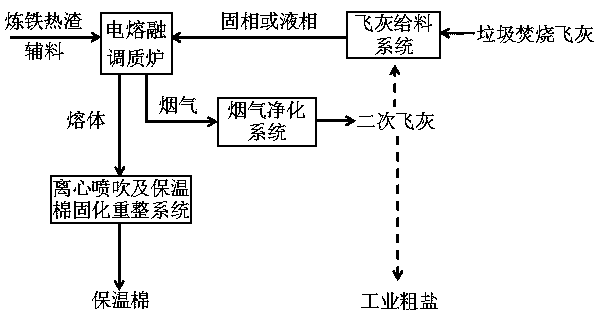

Image

Examples

Embodiment 1

[0027] An embodiment of the present invention provides a thermal insulation cotton made of iron-making hot slag and waste incineration fly ash, including iron-making hot slag, waste incineration fly ash and auxiliary materials with a mass ratio of 1:0.2:0.03.

[0028] Among them, the auxiliary materials include sodium oxide and silicon dioxide with a mass ratio of 1:5.

[0029] The preparation method of above-mentioned insulation cotton:

[0030] 1) Introduce hot ironmaking slag at a temperature of 1500°C into the electric melting and tempering furnace, then add waste incineration fly ash and auxiliary materials into the electric melting and tempering furnace in solid form, and melt and mix at 1450°C;

[0031] 2) The melt is subjected to centrifugal blowing and pendulum laying to obtain a cotton board, and the cotton board is solidified, reformed and cut to obtain the insulation cotton.

Embodiment 2

[0033] An embodiment of the present invention provides a thermal insulation cotton made of iron-making hot slag and waste incineration fly ash, including iron-making hot slag, waste incineration fly ash and auxiliary materials with a mass ratio of 1:0.2:0.03.

[0034] Among them, the auxiliary materials include sodium oxide and silicon dioxide with a mass ratio of 1:5.

[0035] The preparation method of above-mentioned insulation cotton:

[0036] 1) Introduce hot ironmaking slag at a temperature of 1500°C into the electric melting and tempering furnace, then mix the waste incineration fly ash and auxiliary materials evenly and melt them at 1200°C, then add the molten mixture of waste incineration fly ash and auxiliary materials into the Melting and mixing at 1450°C in an electric melting and tempering furnace;

[0037] 2) The melt is subjected to centrifugal blowing and pendulum laying to obtain a cotton board, and the cotton board is solidified and reformed to obtain the ins...

Embodiment 3

[0039] An embodiment of the present invention provides a thermal insulation cotton made of iron-making hot slag and waste incineration fly ash, including iron-making hot slag, waste incineration fly ash and auxiliary materials with a mass ratio of 1:0.2:0.03.

[0040] Among them, the auxiliary materials include sodium oxide and silicon dioxide with a mass ratio of 1:5.

[0041] The preparation method of above-mentioned insulation cotton:

[0042] 1) Introduce hot ironmaking slag at a temperature of 1500°C into the electric melting and tempering furnace, then mix the waste incineration fly ash and auxiliary materials evenly and preheat at 800°C, and then put the preheated waste incineration fly ash and auxiliary materials into The preheated mixture is added to the electric melting and tempering furnace, and melted and mixed at 1450°C;

[0043] 2) The melt is subjected to centrifugal blowing and pendulum laying to obtain a cotton board, and the cotton board is solidified and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com