Manufacturing process of paper cup

A production process and technology of paper cups, which are applied in box production operations, rigid/semi-rigid container manufacturing, papermaking, etc., can solve the problems of increasing liquid pouring in paper cups, affecting human hand holding, and easy loosening, etc., so as to be easy for human hands to hold Maintain, ensure production efficiency, and reduce the effect of burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

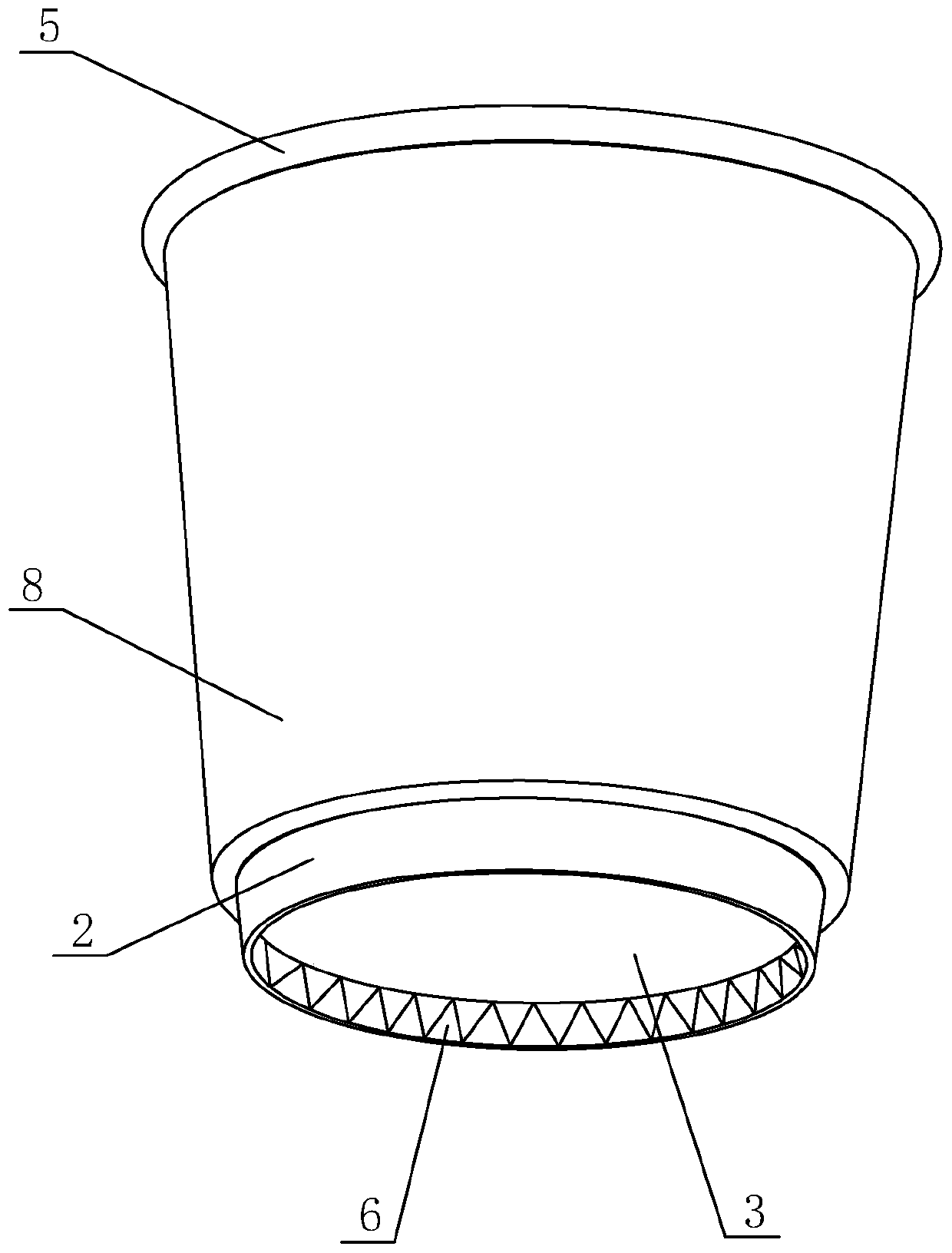

[0049] refer to figure 1 , which is a paper cup disclosed by the present invention, comprising an inner core and an outer casing 8 both in the shape of a truncated cone, and the outer casing 8 is sleeved on the outer peripheral side wall of the inner core. The inner core includes a cup body 2 and a cup bottom 3. The upper end surface of the inner core is open and rolled outward to form a roll opening 5. The diameter of the upper end surface of the inner core is larger than the diameter of the lower end surface.

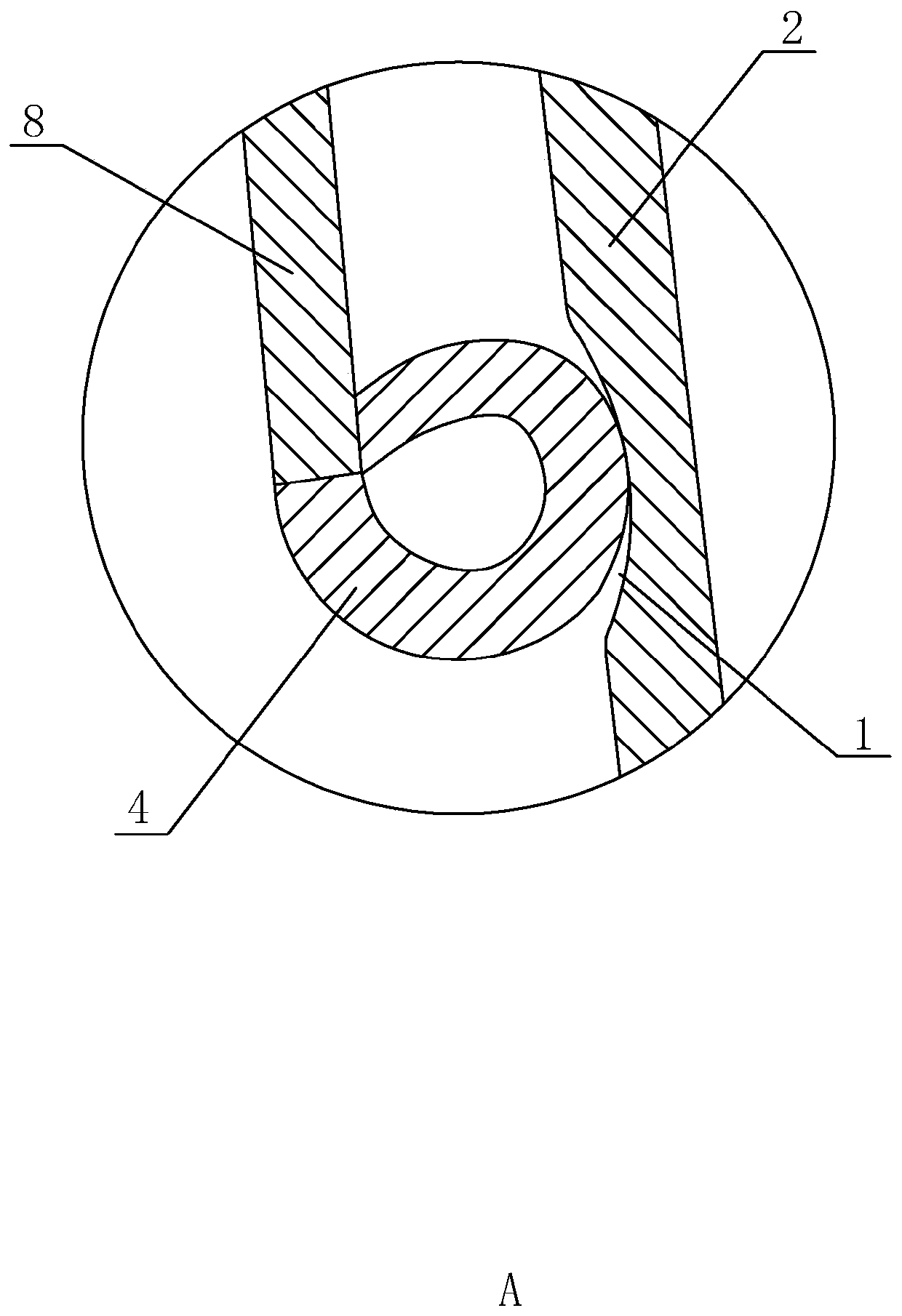

[0050] refer to figure 2 and image 3 Both ends of the outer casing 8 are provided with openings, and the lower end face of the outer casing 8 is rolled inward to form a roll bottom 4. The diameter of the roll bottom 4 is larger than the diameter of the lower end face of the inner core but smaller than the diameter of the upper end face of the inner core.

[0051] refer to image 3 and Figure 4 , the inner wall of the outer casing 8 is embossed with embossing 7 ...

Embodiment 2

[0055]A process for making a paper cup disclosed in the present invention is used to produce the paper cup disclosed in the first embodiment, including: making an inner core, making an outer jacket 8, and gluing the paper cup.

[0056] Among them, refer to figure 1 and image 3 , the steps for making the inner core are as follows:

[0057] S1, one side of the base paper is coated with PE film with a laminating machine to form raw paper, and the raw paper is cut to form a small rectangular sheet for making the cup bottom 3 and a large rectangular sheet for making the cup body 2.

[0058] S2, use a die-cutting machine for die-cutting in the large rectangular sheet, and die-cut a plurality of inner fan ring sheets for making the cup body 2 .

[0059] S3, embossing an arc-shaped concave groove 1 on the side of the inner fan ring sheet away from the PE film, the radian of the groove 1 is the same as that of the arc edge of the inner fan ring sheet, and the groove 1 is close to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com