Small unsealing force packer

A packer and unpacking technology, used in sealing/packing, wellbore/well components, earth-moving drilling, etc., can solve the problem of large unpacking load, low-force unpacking characteristics, and the operation derrick can not meet the multi-stage classification Problems such as the demand for unsealing load of injection wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

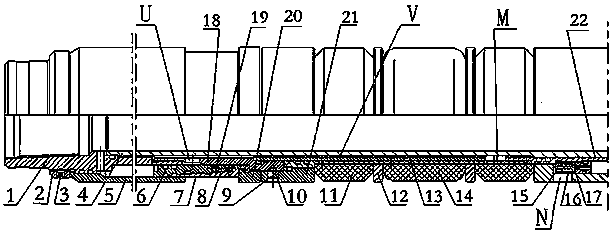

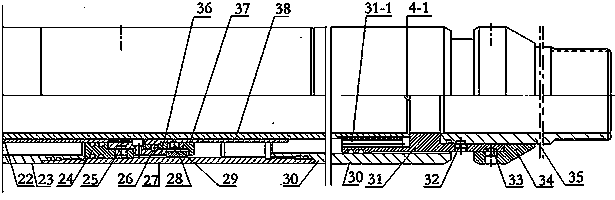

[0017] See Figure 1-2 , the upper end of the small unsealing force packer, that is, the upper joint 1 is processed with an inner tapered pipe thread connected with the tubing, the upper joint 1 and the central pipe 4 are connected by threads, and the upper joint 1 is equipped with a well flushing piston sleeve 5 and a back cap 2 Tighten the well flushing piston sleeve 5 to the outside of the upper joint 1 through threaded connection and tighten it with the set screw 3. The skeleton rubber ring 19 and the retaining ring 8 are sequentially installed in the protection ring 7 and connected to the upper piston 6 through threads. The upper piston 6 assembly can slide freely on the lower part of the upper joint 1, the pressure cap 20 is screwed on the well flushing piston seat 18, the pressure cap 20 is equipped with a T-shaped rubber ring, and the well flushing piston seat 18 is screwed on the lower end of the upper joint 1, The connecting pipe 13 is screwed on the well flushing pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com