Novel polyacrylamide for oil displacement

A polyacrylamide and acrylamide technology, which is applied to drilling compositions, chemical instruments and methods, etc., can solve the problems of low displacement efficiency, high surface tension, low oil displacement efficiency, etc. The effect of low surface tension and high oil displacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

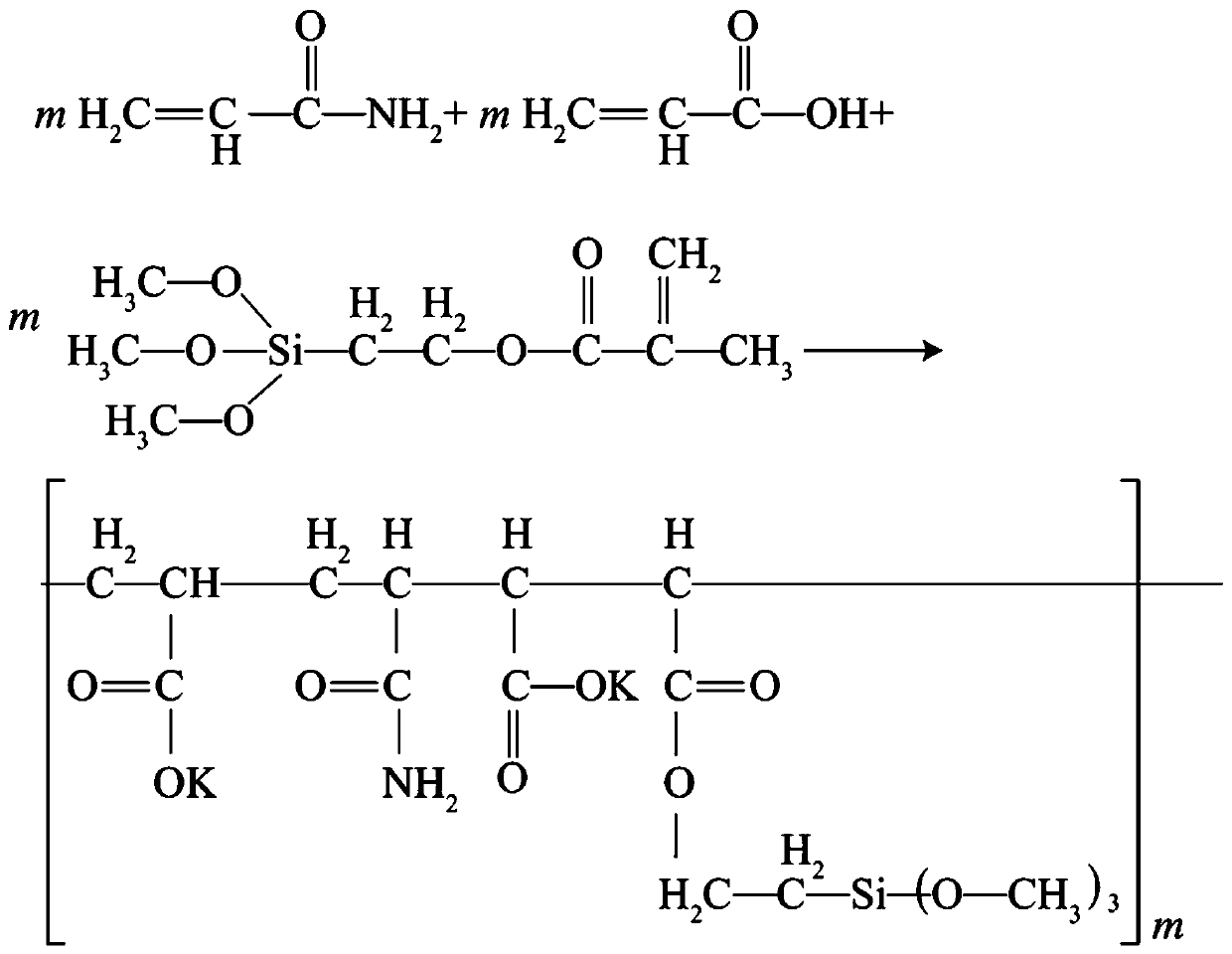

[0022] see figure 1 , the present invention provides a technical solution of a novel polyacrylamide for oil displacement: a novel polyacrylamide for oil displacement, comprising the following steps:

[0023] Step 1: Add acrylamide, acrylic acid, and KH570 into a three-necked flask in proportion, and add distilled water as a solvent to prepare a mixed solution A;

[0024] Step 2: Cover and seal, stir evenly on an electromagnetic stirrer, place in a water bath at constant temperature, adjust the pH value, and drop 0.5% of the monomer mass initiator into the bottle to prepare solution B;

[0025] Step 3: standing for reaction to obtain the required solution, and cooling it;

[0026] Step 4: Transfer the reaction mixture to a beaker, add ethanol to soak, and at the same time cut the reaction mixture to the size of a grain of rice with scissors, and replace the ethanol in due course until the polymer completely becomes a hard white granular solid;

[0027] Step 5: Transfer the wh...

Embodiment 2

[0036] see figure 1 , the present invention provides a technical solution of a novel polyacrylamide for oil displacement: a novel polyacrylamide for oil displacement, comprising the following steps:

[0037] Step 1: Add acrylamide, acrylic acid, and KH570 into a three-necked flask in proportion, and add distilled water as a solvent to prepare a mixed solution A;

[0038] Step 2: Cover and seal, stir evenly on an electromagnetic stirrer, place in a water bath at constant temperature, adjust the pH value, and drop 0.5% of the monomer mass initiator into the bottle to prepare solution B;

[0039] Step 3: standing for reaction to obtain the required solution, and cooling it;

[0040] Step 4: Transfer the reaction mixture to a beaker, add ethanol to soak, and at the same time cut the reaction mixture to the size of a grain of rice with scissors, and replace the ethanol in due course until the polymer completely becomes a hard white granular solid;

[0041] Step 5: Transfer the wh...

Embodiment 3

[0050] see figure 1 , the present invention provides a technical solution of a novel polyacrylamide for oil displacement: a novel polyacrylamide for oil displacement, comprising the following steps:

[0051] Step 1: Add acrylamide, acrylic acid, and KH570 into a three-necked flask in proportion, and add distilled water as a solvent to prepare a mixed solution A;

[0052] Step 2: Cover and seal, stir evenly on an electromagnetic stirrer, place in a water bath at constant temperature, adjust the pH value, and drop 0.5% of the monomer mass initiator into the bottle to prepare solution B;

[0053] Step 3: standing for reaction to obtain the required solution, and cooling it;

[0054] Step 4: Transfer the reaction mixture to a beaker, add ethanol to soak, and cut the reaction mixture to the size of a grain of rice with scissors, and replace the ethanol in due course until the polymer completely becomes a hard white granular solid;

[0055] Step 5: Transfer the white granular poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com