A kind of oil displacing agent and preparation method thereof

A technology of oil displacement agent and ammonium chloride, which is applied in the field of chemical flooding, can solve the problems of poor oil washing effect, high agent cost, and low input-output ratio, and achieve the effects of increased oil recovery, low price, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

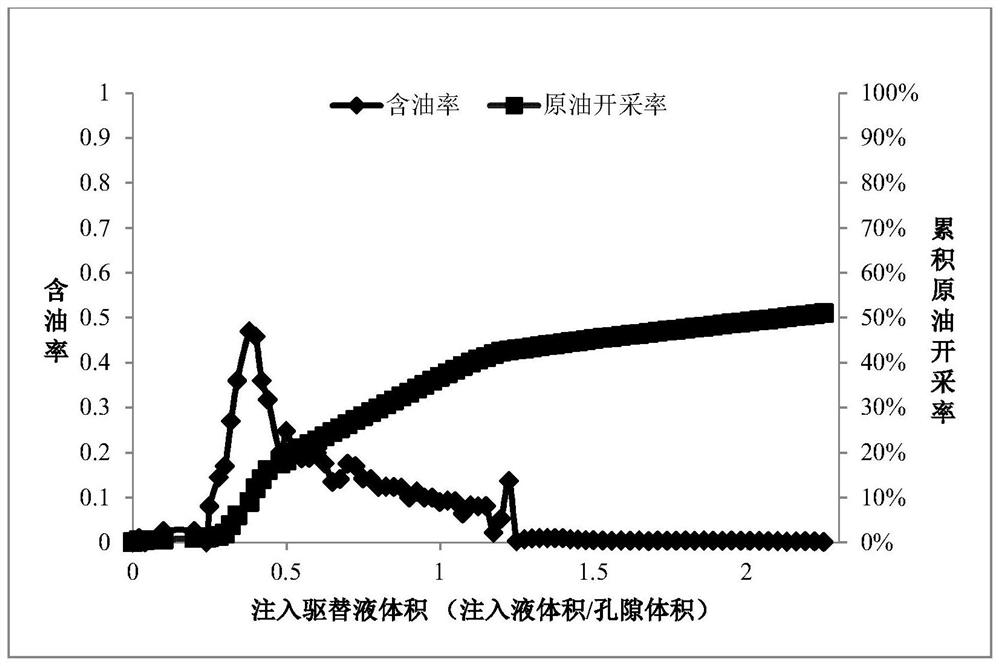

Image

Examples

Embodiment 1

[0035] Open the stirring of stirring reactor, first 6kg isopropanol is added in stirring reactor, then 30kg nonylphenol polyoxyethylene ether (9) carboxylate, 15kg dodecyl / tetradecyl alcohol polyoxyethylene ether (9) ), 20kg propylene bis[(dodecyl hydroxyethyl methyl) ammonium chloride], 11kg dodecyl / tetradecyl alcohol polyoxyethylene ether (2) sodium sulfate, 10kg docusate sodium, 8kg sophora The glycolipid is added into the stirred reactor, and the temperature of the stirred reactor is maintained at 30° C., and the raw materials therein are stirred until they are colorless and transparent to obtain an oil displacing agent.

Embodiment 2

[0037] Start the stirring of the stirred reactor, first add 6kg isopropanol in the stirred reactor, then add 15kg dodecyl / tetradecyl alcohol polyoxyethylene ether (9) carboxylate, 10kg dodecyl / tetradecyl alcohol polyoxyethylene Vinyl ether (5), 50kg ethylene group bis[(octadecyl dimethyl) ammonium chloride], 6kg dodecyl / tetradecyl alcohol polyoxyethylene ether (3) sodium sulfate, 8kg docusate sodium, Add 5 kg of sophorolipids into the stirred reactor, and maintain the temperature of the stirred reactor at 35° C., stir the raw materials therein until it is colorless and transparent, and obtain the oil displacing agent.

Embodiment 3

[0039]Start the stirring of the stirred reactor, first add 8kg of isopropanol in the stirred reactor, then add 19kg of isomeric tridecyl alcohol polyoxyethylene ether (9) carboxylate, 11kg of dodecyl / tetradecyl alcohol polyoxyethylene ether (7), 32kg ethylene group bis[(hexadecyl amido dimethyl) ammonium chloride], 5kg lauryl / tetradecyl alcohol polyoxyethylene ether (2) sodium sulfate, 12kg lauryl polyoxyethylene Disodium ether sulfosuccinate and 13 kg of sophorolipids were added into the stirred reactor, and the temperature of the stirred reactor was maintained at 40° C., and the raw materials therein were stirred until colorless and transparent to obtain an oil displacing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com