Method for extracting collagen from silver carp skins by ultrasonic acid pretreatment assisted acid-enzyme method

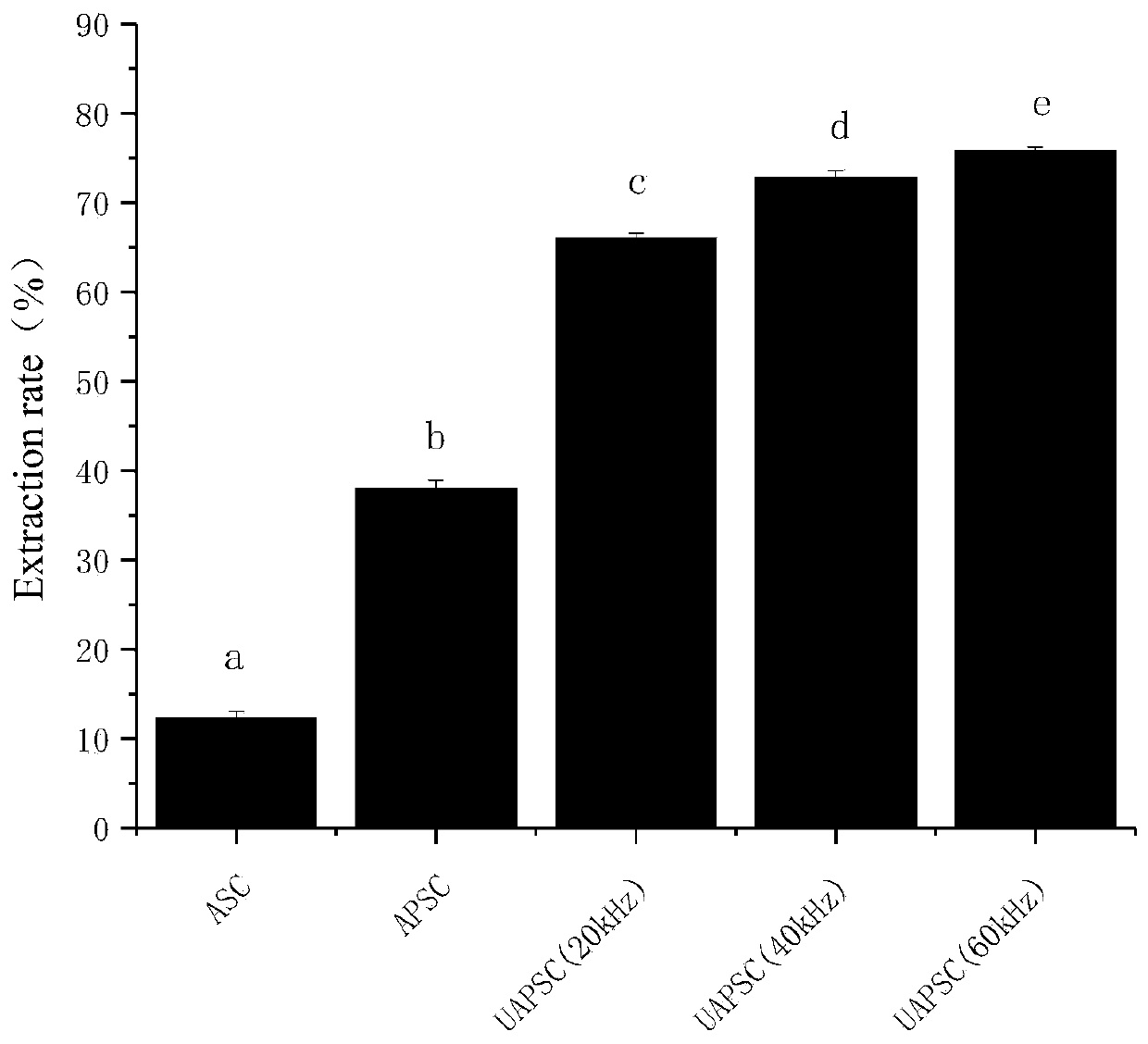

A fish skin collagen and acid pretreatment technology, which is applied to the preparation methods of peptides, chemical instruments and methods, animal/human proteins, etc., can solve the problems of waste of resources and low extraction rate, and achieve convenient nutrition, simple operation and stability. low sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

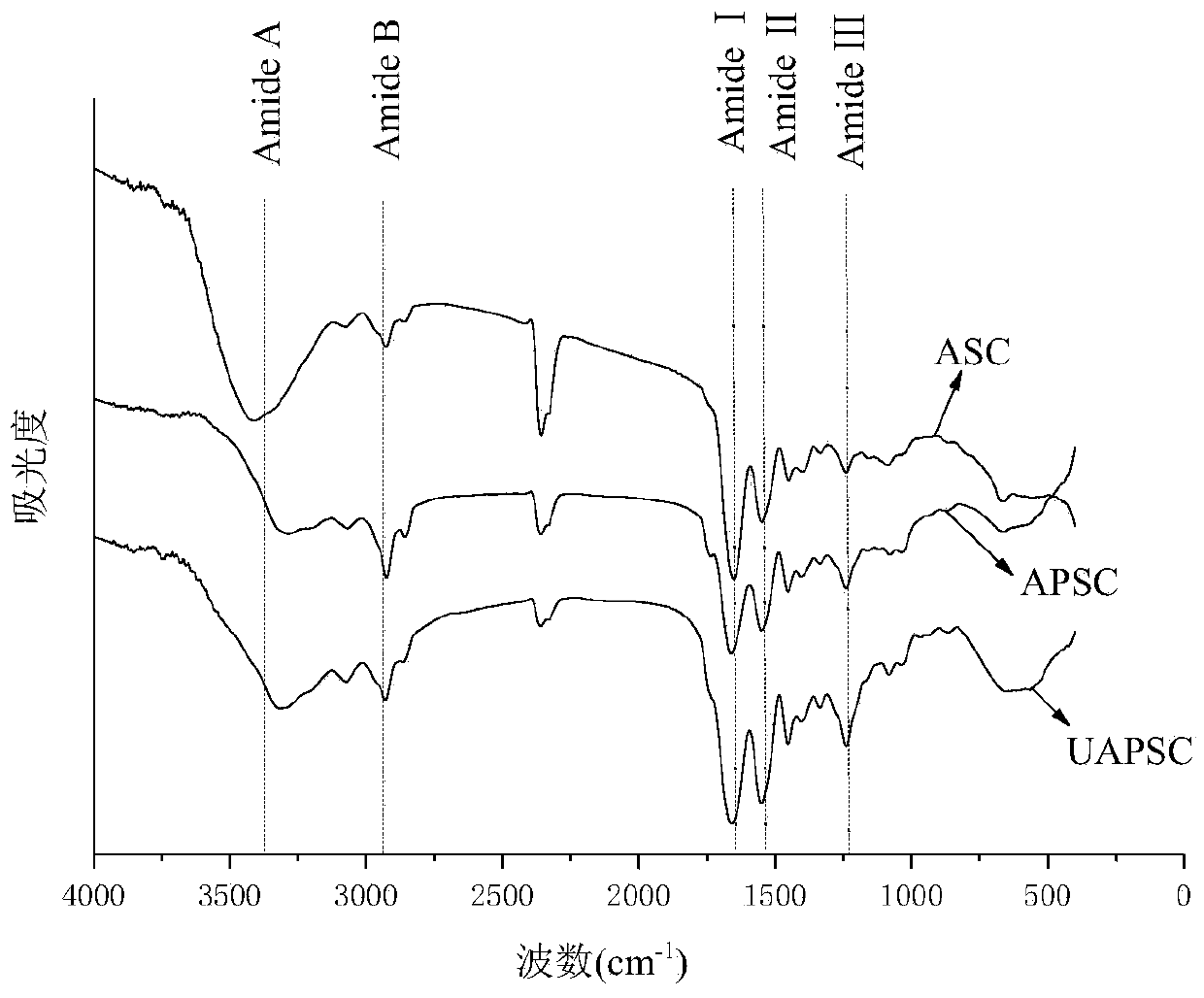

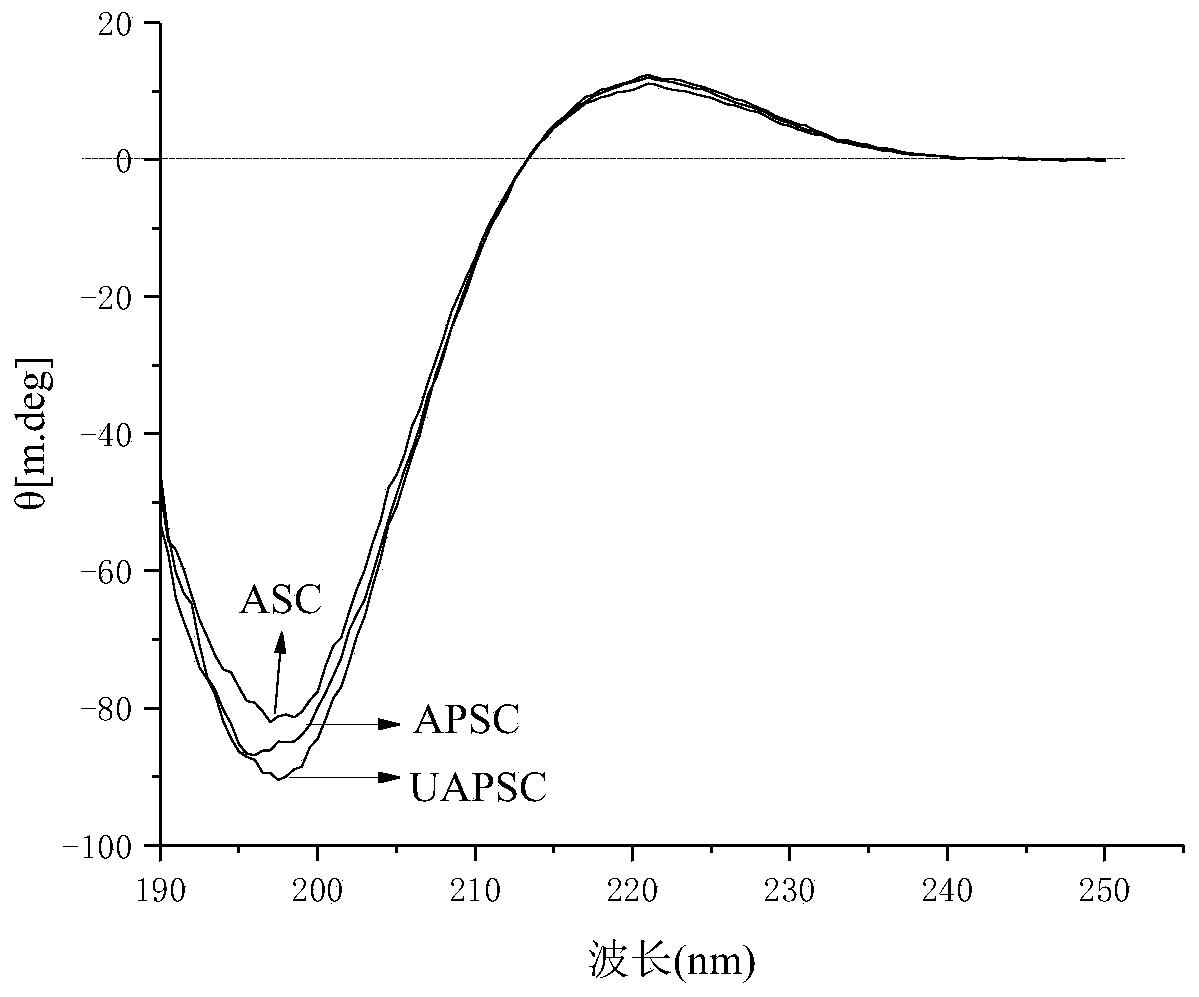

Method used

Image

Examples

Embodiment 1

[0036] (1) Pretreatment of raw materials:

[0037] Recover the leftovers from the leftovers of the fish ball factory, pick out the fish skin, wash and cut into pieces (1cm×1cm), freeze-dried and then use it directly, or store it at -20°C for later use; take the freeze-dried fish skin and store it In 0.1mol / L NaOH solution, the mass volume ratio of freeze-dried fish skin to NaOH solution is 1:25; soak for 6 hours after homogeneous stirring for 5 minutes, replace the lye every 2 hours during the soaking period, remove impurities and pigments; use after soaking Rinse with distilled water until the pH is neutral, then soak the filtered fish skin again in isopropanol solution for degreasing, wherein the mass volume ratio of filtered fish skin to isopropanol solution is 1:10, and the degreasing time is 9 hours During the degreasing period, the isopropanol solution was replaced every 3 hours; after degreasing, it was centrifuged at 10000g for 30min at 4°C to obtain the pretreated fis...

Embodiment 2

[0042] (1) Pretreatment of raw materials:

[0043]Recover the leftovers from the leftovers of the fish ball factory, pick out the fish skin, wash and cut into pieces (1cm×1cm), freeze-dried and then use it directly, or store it at -20°C for later use; take the freeze-dried fish skin and store it In 0.1mol / L NaOH solution, the mass volume ratio of freeze-dried fish skin to NaOH solution is 1:25; soak for 6 hours after homogeneous stirring for 5 minutes, replace the lye every 2 hours during the soaking period, remove impurities and pigments; use after soaking Rinse with distilled water until the pH is neutral, then soak the filtered fish skin again in isopropanol solution for degreasing, wherein the mass volume ratio of filtered fish skin to isopropanol solution is 1:10, and the degreasing time is 9 hours During the degreasing period, the isopropanol solution was replaced every 3 hours; after degreasing, it was centrifuged at 10000g for 30min at 4°C to obtain the pretreated fish...

Embodiment 3

[0048] (1) Pretreatment of raw materials:

[0049] Recover the leftovers from the leftovers of the fish ball factory, pick out the fish skin, wash and cut into pieces (1cm×1cm), freeze-dried and then use it directly, or store it at -20°C for later use; take the freeze-dried fish skin and store it In 0.1mol / L NaOH solution, the mass volume ratio of freeze-dried fish skin to NaOH solution is 1:25; soak for 6 hours after homogeneous stirring for 5 minutes, replace the lye every 2 hours during the soaking period, remove impurities and pigments; use after soaking Rinse with distilled water until the pH is neutral, then soak the filtered fish skin again in isopropanol solution for degreasing, wherein the mass volume ratio of filtered fish skin to isopropanol solution is 1:10, and the degreasing time is 9 hours During the degreasing period, the isopropanol solution was replaced every 3 hours; after degreasing, it was centrifuged at 10000g for 30min at 4°C to obtain the pretreated fis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com