Sewage anaerobic reactor

An anaerobic reactor and anaerobic reaction technology, applied in the direction of gas production bioreactor, bioreactor/fermenter combination, anaerobic digestion treatment, etc., can solve the problem of poor slagging effect of anaerobic reactor, and achieve Improve the effect of slag discharge, reduce pollution and reduce the effect of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

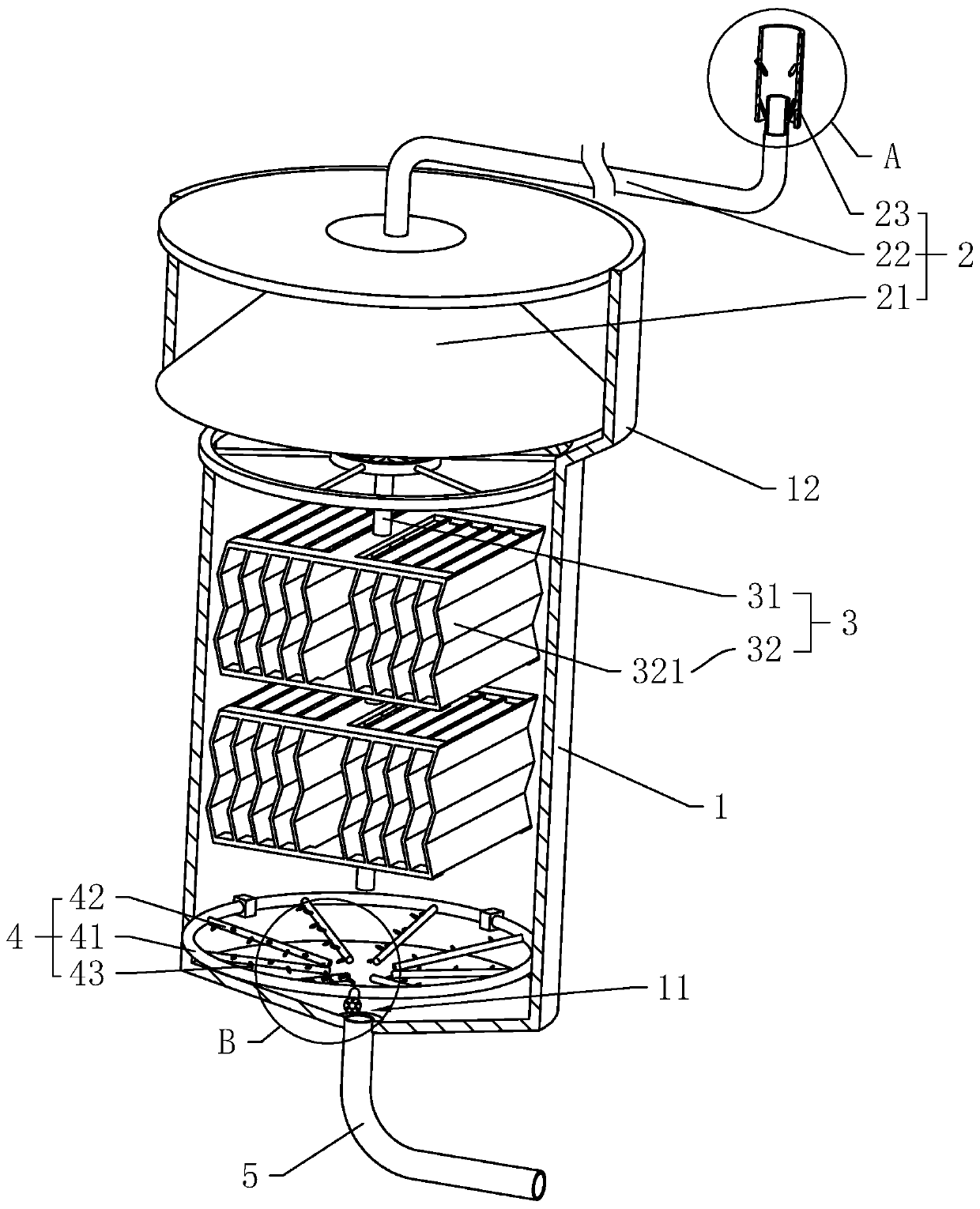

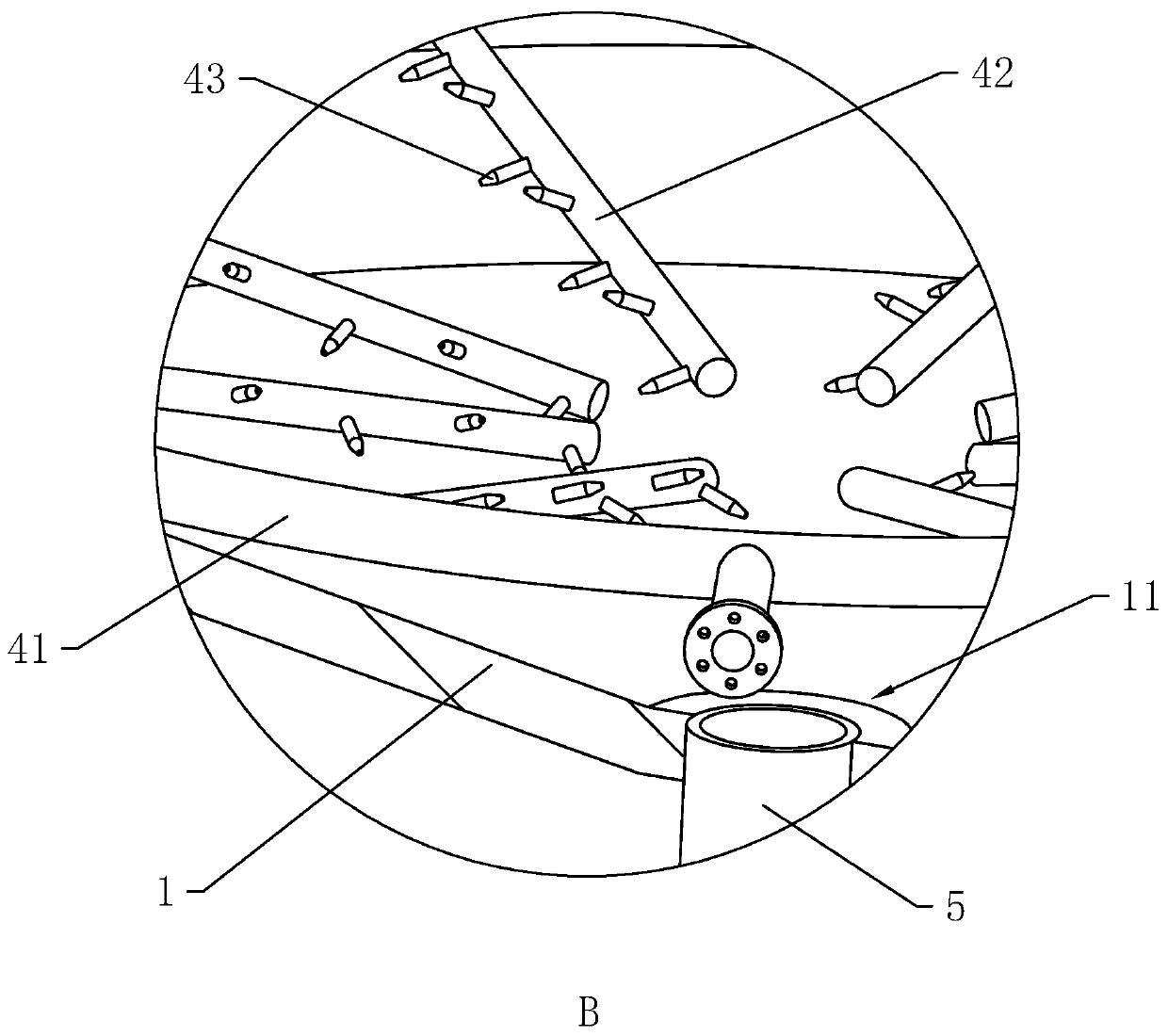

[0037] Such as figure 1 As shown, a sewage anaerobic reactor includes a tower body 1, a water distribution device 4, and a sewage pipe 5. The tower body 1 is cylindrical, and the inner bottom of the tower body 1 is conical. The conical structure makes the tower body A funnel-shaped sediment sink 11 is formed at the inner bottom of the tower body 1, and the conical surface at the inner bottom of the tower body 1 is set at an angle of 19° from the horizontal plane.

[0038] The inclination angle of the inner bottom of the tower body 1 is set according to the size of the tower body 1. In general, like an anaerobic device used in a paper mill, the diameter of the tower body 1 is generally about 5m, and the tower height is generally about 20m, while 19° According to the calculation of tan19°=h / r=0.34, the thickness of the cushion layer at the inner bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com