Molten iron pretreatment slag collecting agent

A technology of molten iron pretreatment and slag collecting agent, which is applied in mechanical cleaning, manufacturing tools, metal processing equipment, etc., to achieve the effect of reducing the amount of slag in molten iron, small iron loss, and improving the conditions of molten iron entering the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

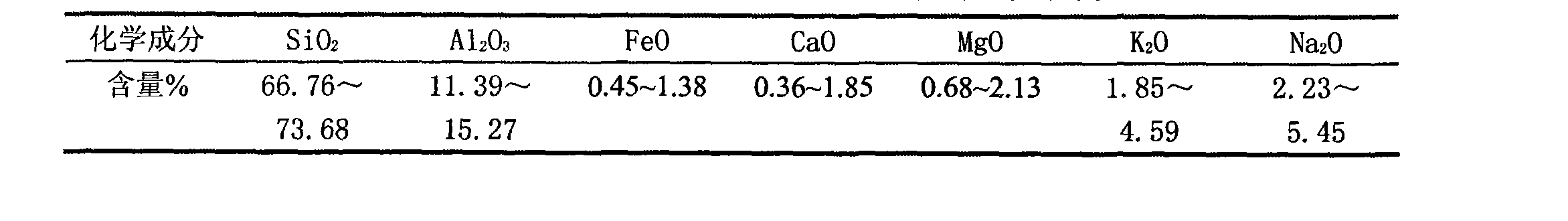

[0017] An embodiment of the present invention is: the molten iron pretreatment slag collecting agent that is used for gray cast iron, through material selection, according to the following ratio: 75% of perlite, 10% of potassium albite feldspar, 15% of white sand, respectively pulverized into particle size 20-40 mesh granular, then dried at 70°C, then mixed ingredients according to the above ratio, stirred evenly, and packed in moisture-proof bags after inspection. Its working temperature is 1300-1400°C, and the addition amount is 0.2-0.3% of the weight of the liquid metal. The addition method is: use a shovel or a special tool to shove evenly on the surface of the liquid metal in the ladle. After trial, the slag removal time is reduced by 2 / 3 compared with that without slag collector, and the iron loss of iron slag is reduced from an average of 6.25Kg / t iron to below 1Kg / t iron.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com