Pickling purification method of iron disulfide

A technology of ferric disulfide acid and purification method, which is applied in the directions of iron sulfide, electrical components, battery electrodes, etc., can solve the problems of low purity of iron disulfide products, and achieve the effects of low equipment requirements, simple process operation, and improved purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

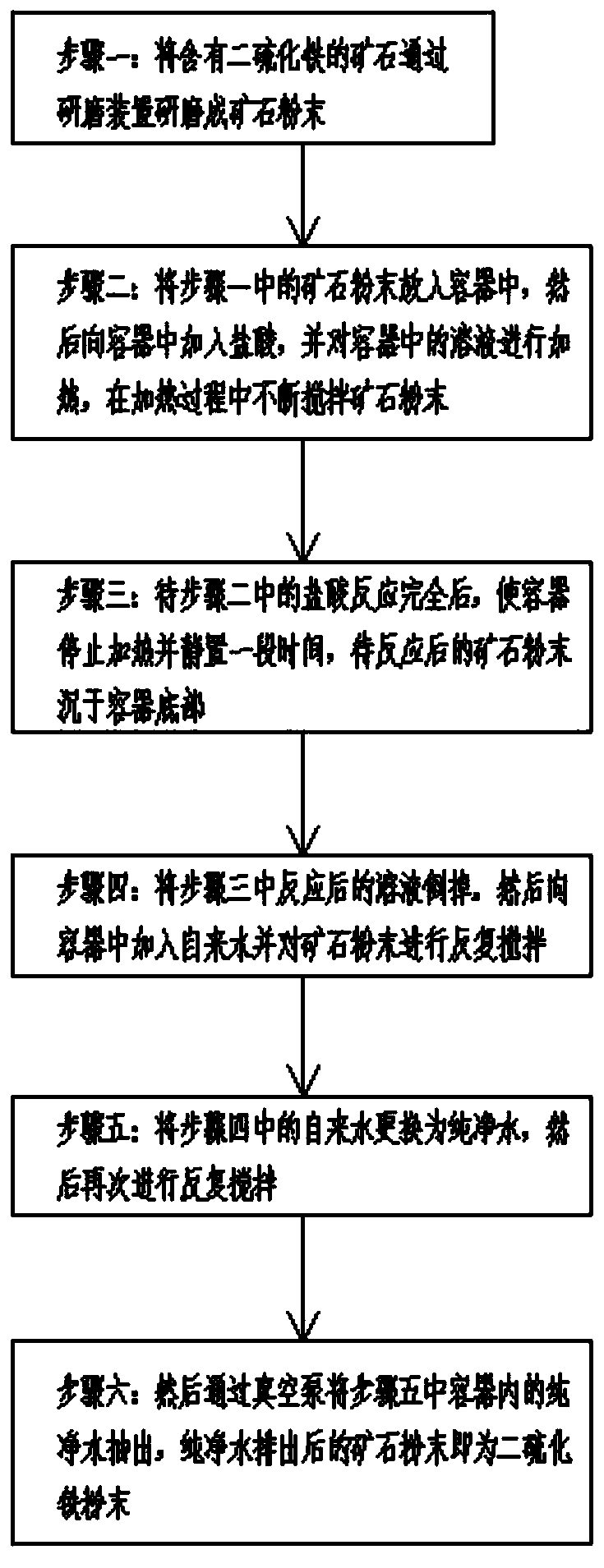

[0018] A method for pickling and purifying iron disulfide, comprising the steps of:

[0019] Step 1: Grind the ore containing iron disulfide into ore powder with a particle size of 80-320 mesh through a grinder; the powdered ore can increase the reaction speed with hydrochloric acid in the subsequent impurity removal process, improving the operating efficiency. efficiency.

[0020] Step 2: Put the ore powder in step 1 into a glass vessel, then add hydrochloric acid (wherein the volume ratio of hydrochloric acid to ore powder is 1:1, and the concentration of hydrochloric acid is 1.19g / mL) to the glass vessel, and then apply the The solution in the vessel was heated to 95°C, and the ore powder in the solution was continuously stirred during the heating process, and the results in Table 1 were obtained by heating the solution for different times:

[0021] Table 1 (heating temperature is 95°C):

[0022] heating time 1 hour 3 hours 5 hours The purity of iron ...

Embodiment 2

[0029] A method for pickling and purifying iron disulfide, comprising the steps of:

[0030] Step 1: Grind the ore containing iron disulfide into ore powder with a particle size of 80-320 mesh through a grinder; the powdered ore can increase the reaction speed with hydrochloric acid in the subsequent impurity removal process, improving the operating efficiency. efficiency.

[0031] Step 2: Put the ore powder in step 1 into a glass vessel, then add hydrochloric acid (wherein the volume ratio of hydrochloric acid to ore powder is 1:1, and the concentration of hydrochloric acid is 1.19g / mL) to the glass vessel, and then apply the The solution in the container was heated for 4 hours and the temperature of the solution was gradually raised, and the ore powder in the solution was constantly stirred during the heating process, and the results in Table 2 were obtained by changing the heating temperature of the solution:

[0032] Table 2 (heating time is 4 hours):

[0033] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com