Automatic assembly device for RF line terminal

A technology of automatic assembly and equipment, applied in the assembly/disassembly of contacts, antenna connectors, contact manufacturing, etc., can solve the problem of inability to meet the development trend of high efficiency, high quality and low cost, difficult to choose between processing output and processing cost, no Operation mode automation equipment and other issues, to achieve the effect of intelligent and continuous assembly production, high degree of automation, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

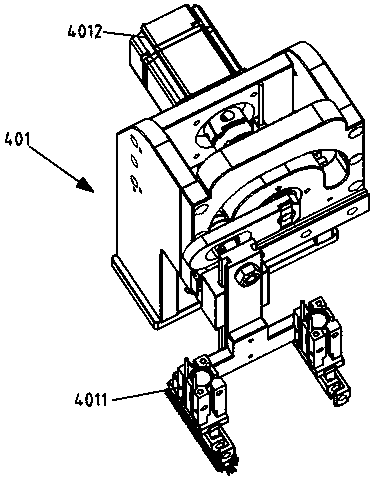

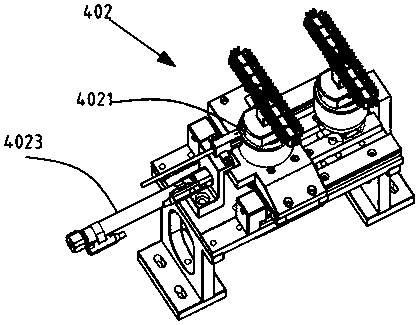

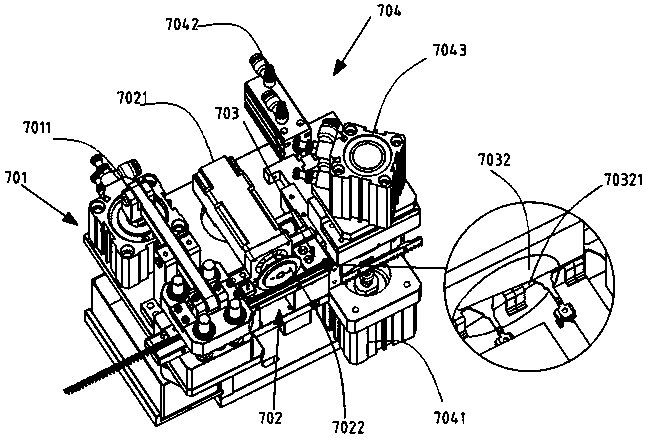

[0050] Embodiment: a kind of RF wire end automatic assembly equipment, such as Figure 1.1 and Figure 1.2 As shown, it includes a machine 10 and a plastic sleeve discharge device 20 provided on the machine, a plastic sleeve feeding and cutting station 30, a plastic sleeve handling and cutting rotary station 40, a main rotary table 50, and a terminal discharging Device 60, terminal cutting and feeding pressing station 70, shell discharging device 80, shell feeding and pressing station 90, semi-finished interpolation station 110, finished product folding belt station 120 and finished product inspection station 130;

[0051] The plastic sleeve feeding and cutting station is located downstream of the plastic sleeve discharging device, and the plastic sleeve handling and cutting rotary station is located downstream of the plastic sleeve feeding and cutting station;

[0052] The terminal cutting, feeding and pressing station is located downstream of the terminal discharging device;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com