A kind of high-voltage lithium-ion battery ternary cathode material electrolyte and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of high-voltage lithium-ion battery ternary positive electrode material electrolyte and its preparation, can solve the problems of the inability to meet the high-voltage working conditions of the ternary battery, the increase of the interface impedance value between the electrode and the electrolyte, and heat resistance. Poor performance and other problems, to achieve the effect of inhibiting continuous decomposition, promoting reversible deposition, and improving interface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a high-voltage lithium-ion battery ternary cathode material electrolyte, comprising the following steps:

[0029] (1) In an argon-filled room temperature environment, add the electrolyte lithium salt mixture into a high-pressure resistant organic solvent, stir until the lithium salt is completely dissolved to obtain a lithium salt solution, in which the content of the lithium salt mixture is 15%, including lithium hexafluorophosphate and difluorophosphate Lithium, the mass ratio of lithium hexafluorophosphate and lithium phosphate salt is 1:1, the organic solvent content of high pressure resistance is 71.2%-79.7%, including cyclic carbonates of ethylene carbonate and propylene carbonate; dimethyl carbonate, dicarbonate Chain carbonate of ethyl ester; succinonitrile, wherein the mass ratio of cyclic carbonate to chain carbonate is 1:1, and the content of succinonitrile is 1%;

[0030] (2) In the lithium salt solution in step (1), the auxiliary addi...

Embodiment 6-10

[0040]On the basis of Example 1, wherein the lithium salt mixture content is 17%, including lithium hexafluorophosphate and lithium difluorophosphate, the mass ratio of lithium hexafluorophosphate to lithium phosphate salt is 1.5:1, and the organic solvent resistant to high pressure is ethylene carbonate, carbonic acid Cyclic carbonate of propylene ester; chain carbonate of dimethyl carbonate and diethyl carbonate; succinonitrile, wherein the mass ratio of cyclic carbonate to chain carbonate is 1.5:1, and the content of succinonitrile is 2%. The content of tris(pentafluorophenyl)phosphine is 0.2%-1.5%, the content of lithium fluorozirconate is 2%; the flame retardant is dimethyl methylphosphonate and the content is 3%.

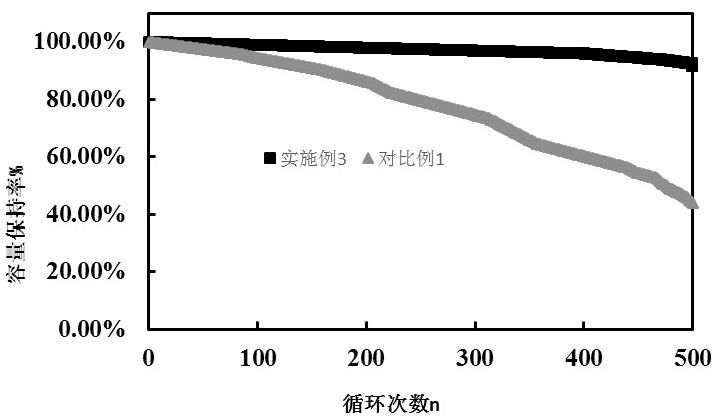

[0041] Considering the effect of the content of tris(pentafluorophenyl)phosphine on the cycle performance of the battery under high pressure conditions when the electrolyte is assembled into a high-voltage ternary cathode material, under the condition that othe...

Embodiment 11-15

[0049] On the basis of Example 1, wherein the lithium salt mixture content is 17%, including lithium hexafluorophosphate and lithium difluorophosphate, the mass ratio of lithium hexafluorophosphate to lithium phosphate salt is 1.2:1, and the organic solvent resistant to high pressure is ethylene carbonate, carbonic acid Cyclic carbonate of propylene ester; chain carbonate of dimethyl carbonate and diethyl carbonate; succinonitrile, wherein the mass ratio of cyclic carbonate to chain carbonate is 1.2:1, and the content of succinonitrile is 2.5%. The content of tris(pentafluorophenyl)phosphine is 0.6%, the content of lithium fluorozirconate is 1%-5%; the flame retardant is dimethyl methylphosphonate and the content is 4%.

[0050] Considering the influence of the content of lithium fluorozirconate on the cycle performance of the battery assembled into a high-voltage ternary cathode material under high pressure conditions, the electrolyte was investigated by changing the content o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com