Standard segment pier column and splicing and assembling method thereof

A segmental and standard technology, applied in erection/assembly of bridges, buildings, bridge construction, etc., can solve problems such as high cost, unfavorable design and construction, stress concentration, etc., and achieve improved seismic energy dissipation performance and encrypted energy-dissipating reinforcement layout , Improve the effect of reinforcement congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

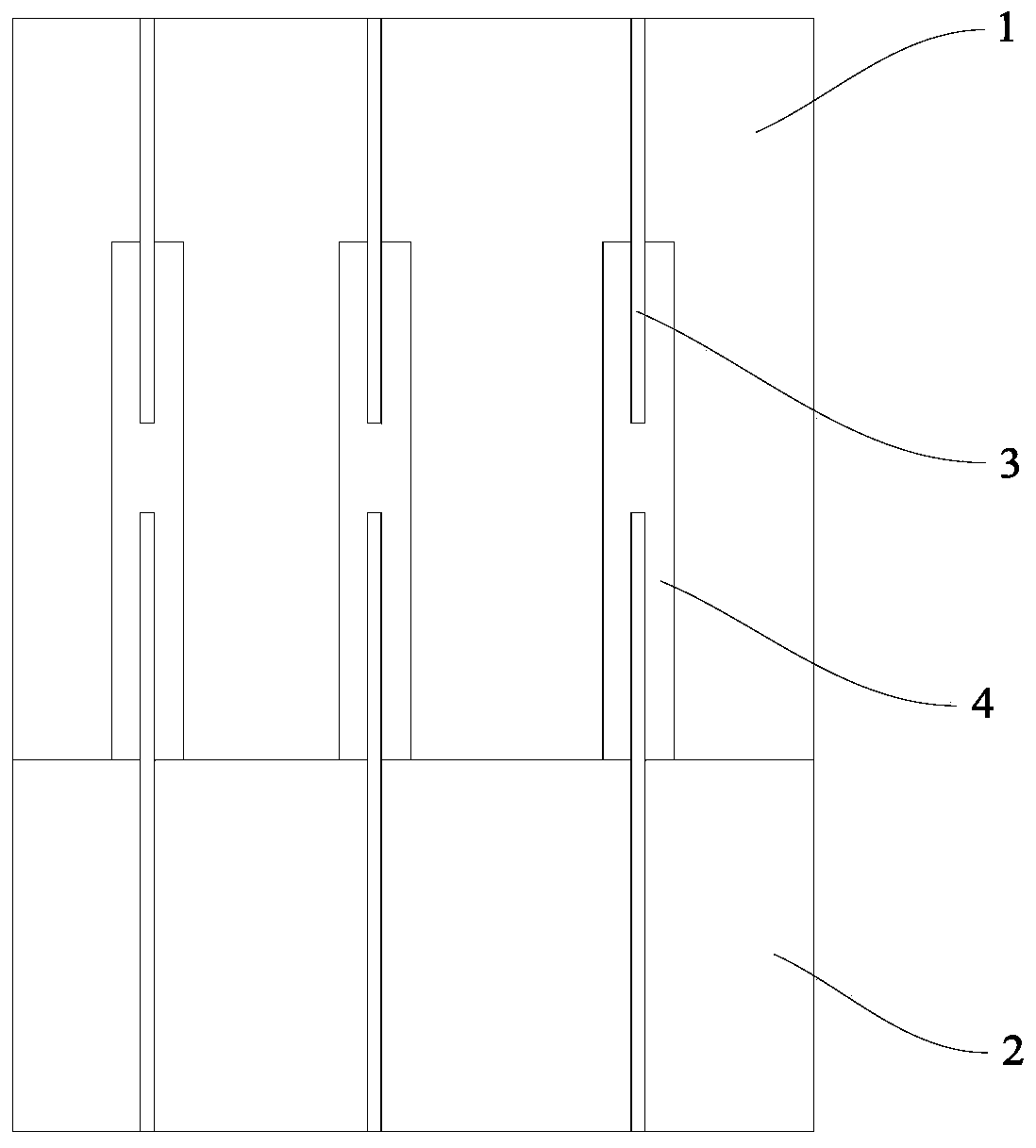

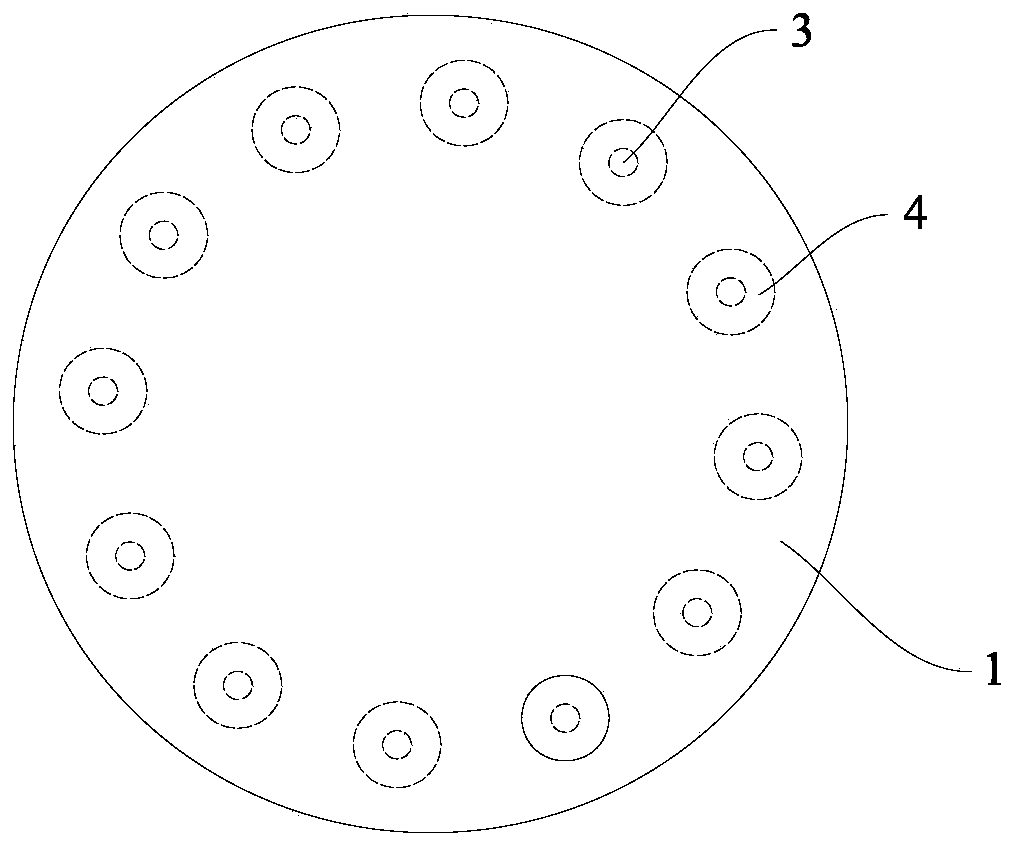

[0077] Such as image 3 As shown, a standard segment unit includes a body 1 on which a female end 2 and a male end 3 are arranged.

[0078] The female end 2 is provided with first longitudinal ribs 21, the first longitudinal ribs 21 are arranged in two layers, and several reserved grooves 22 are arranged between the first longitudinal ribs 21 of the two layers. The head end 3 is provided with a second longitudinal rib 31, the second longitudinal rib 31 is arranged in a single layer, the diameter of the second longitudinal rib 31 is larger than the diameter of the first longitudinal rib 21, two of the first longitudinal ribs The sum of the cross-sectional areas of the ribs 21 is greater than or equal to the cross-sectional area of one second longitudinal rib 31 . Through equal-area substitution, the bending bearing capacity of the two ends of the entire standard segmental unit is basically the same, and the equal-strength design is realized. The main body 1 is also provided...

Embodiment 2

[0086] Such as Figure 8-Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that the distance d between the first longitudinal ribs 21 of the two layers is tapered, and the first end 311 of the second longitudinal ribs 31 is connected to the first end 311 of the two layers. The first longitudinal rib 21 is connected by welding.

Embodiment 3

[0088] Such as Figure 10-Figure 11 As shown, the difference between this embodiment and Embodiment 1 is that the inner wall 42 and the outer wall 43 of the first grouting sleeve 4 are provided with a first slope 41, and the inner wall 2 of the second grouting sleeve 5 53 and the outer wall 2 54 are provided with a suitable second slope 511, the first grouting sleeve 4 and the second grouting sleeve 5 form a slope connection through the first slope 41 and the second slope 511, which can Reduce the requirements for matching accuracy and reduce the difficulty of construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com