Preparation method of polydopamine modified basalt fiber carrier

A technology of basalt fiber and polydopamine, which is applied in fiber treatment, chemical instruments and methods, textiles and papermaking, etc., to achieve the effects of good chemical and biological stability, large specific surface area and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

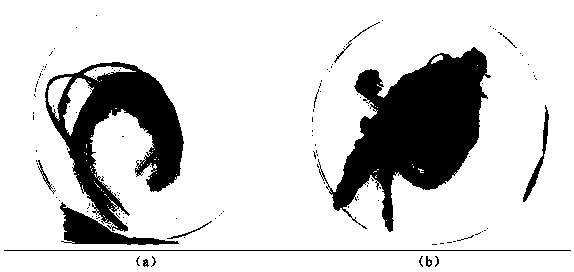

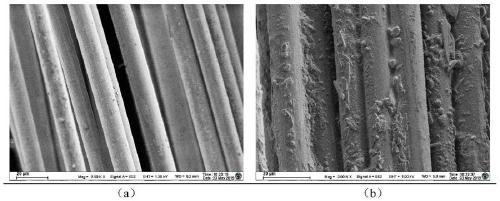

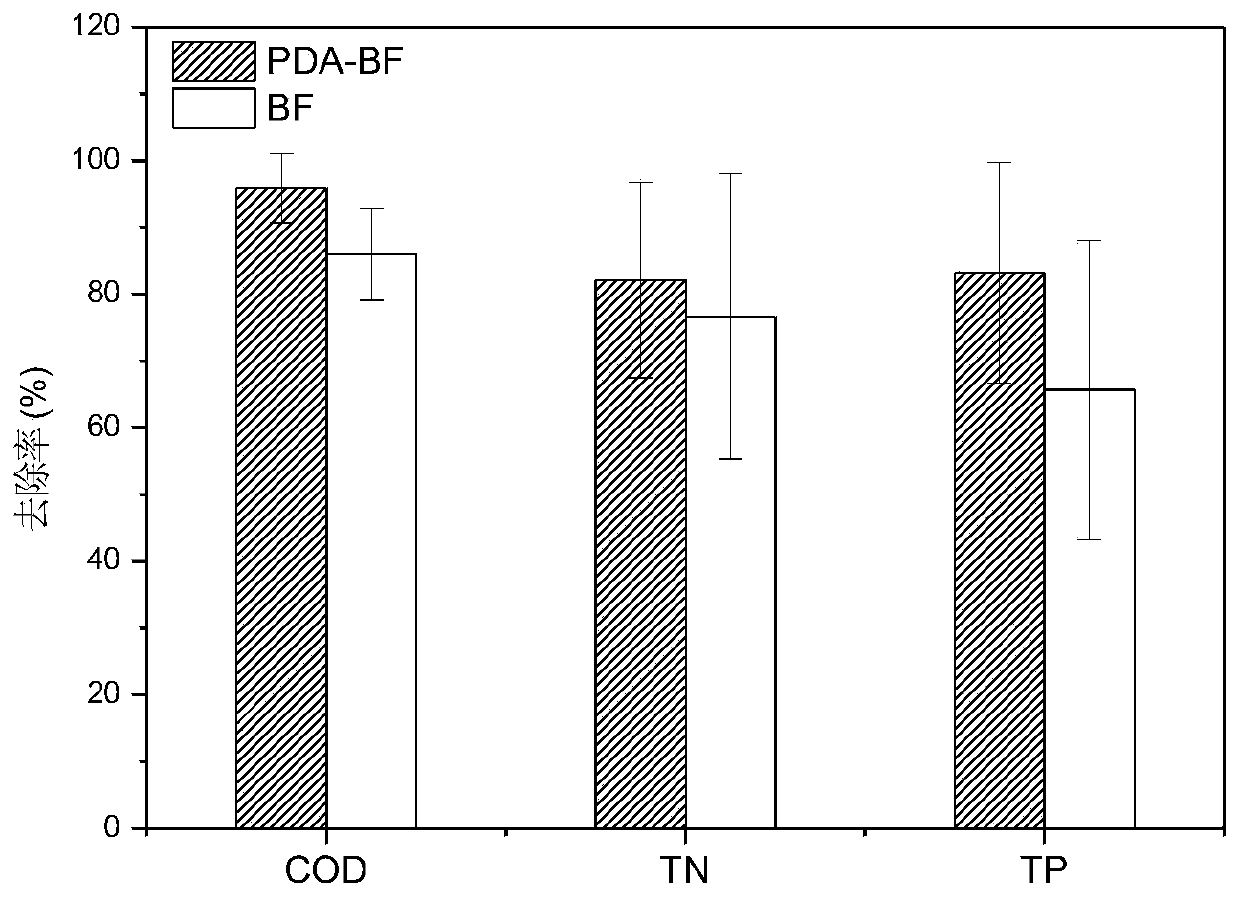

Image

Examples

Embodiment 1

[0034] (1) Weigh 40g of basalt fiber and immerse it into 500ml of acetone solution, put it into an ultrasonic cleaner for cleaning for 3 hours, take it out, wash it repeatedly with deionized water, and dry it at 105°C for 4 hours;

[0035] (2) Prepare a 0.5mol / L NaOH solution, soak the basalt fiber in the NaOH solution, take it out after 2 hours, wash it with deionized water several times until neutral, and dry it for later use;

[0036] (3) Prepare a Tris-HCl buffer solution, weigh a certain amount of Tris solution to obtain a Tris solution with a concentration of 15 mmol / L, and then add HCl in an appropriate amount to adjust the pH to 8.0-8.5;

[0037] (4) prepare dopamine modification solution, take a certain amount of dopamine and ammonium persulfate and dissolve in Tris-HCl buffer solution, make the dopamine modification solution that initial concentration is 2mg / mL;

[0038] (5) Soak the basalt fiber in step (2) in the dopamine modification solution in step (4), place it...

Embodiment 2

[0040] (1) Weigh 40g of basalt fiber and immerse it into 500ml of acetone solution, put it into an ultrasonic cleaner for cleaning for 3 hours, take it out, wash it repeatedly with deionized water, and dry it at 105°C for 4 hours;

[0041] (2) Prepare a 0.5mol / L NaOH solution, soak the basalt fiber in the NaOH solution, take it out after 2 hours, wash it with deionized water several times until neutral, and dry it for later use;

[0042] (3) Prepare a Tris-HCl buffer solution, weigh a certain amount of Tris solution to obtain a Tris solution with a concentration of 15 mmol / L, and then add HCl in an appropriate amount to adjust the pH to 8.0-8.5;

[0043] (4) prepare dopamine modified solution, take a certain amount of dopamine and ammonium persulfate and dissolve in Tris-HCl buffer solution, and make the dopamine modified solution whose initial concentration is 4mg / mL;

[0044] (5) Soak the basalt fiber in step (2) in the dopamine modification solution in step (4), place it in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com