Polyethylene-degradable Pichia guilliermondii

A technology of polyethylene and yeast, applied in the direction of microorganism-based methods, microorganisms, fungi, etc., can solve the problems of air pollution, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

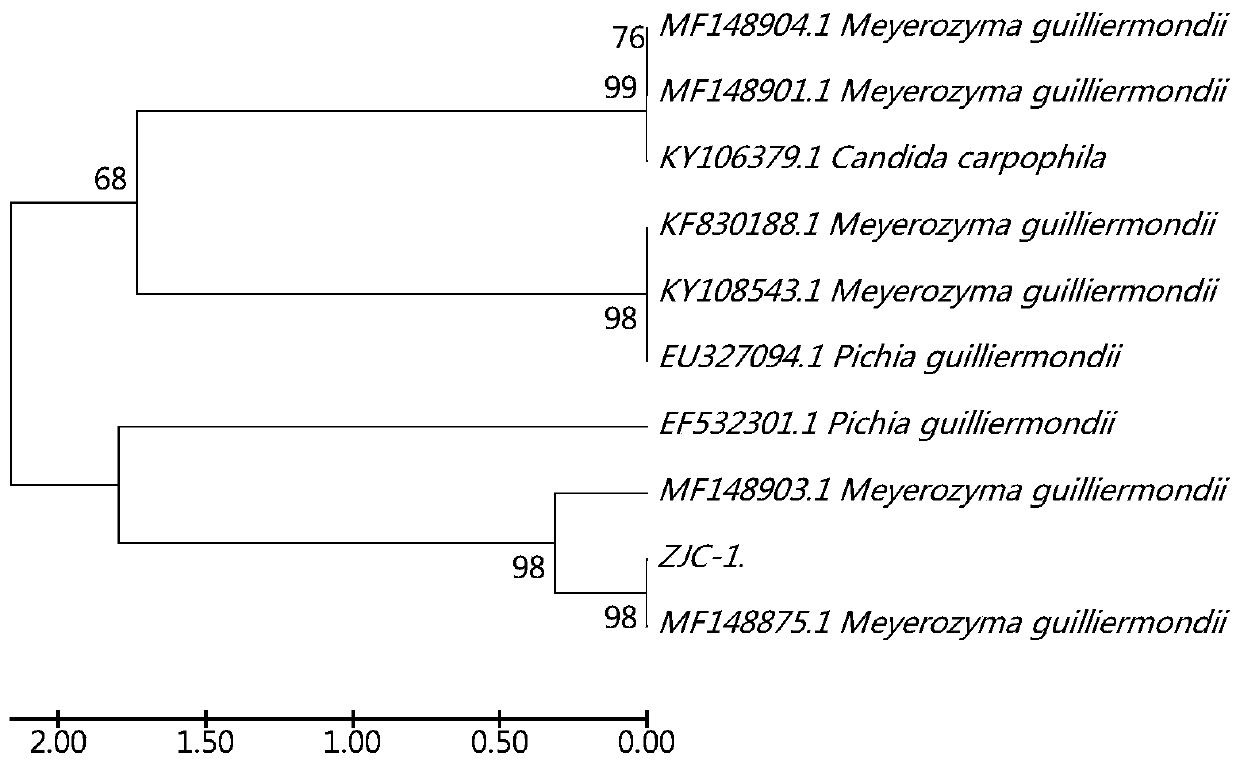

[0014] Specific embodiment 1: Pichia pastoris MeyerozymaguilliermondiiZJC-1, which can degrade polyethylene in this embodiment, is preserved in the General Microbiology Center (CGMCC) of China Microbial Culture Collection Management Committee, and the preservation address is No. 1, Beichen Road, Chaoyang District, Beijing Court No. 3, the deposit date is December 17, 2018, and the deposit number is CGMCCNo: 16956.

[0015] In this embodiment, Pichia guilliermondii ZJC-1 is obtained by screening the intestinal fluid of the larvae of the mellonella mellonella. Filtering is done in the following steps:

[0016] Prepare 100 larvae of the 5th instar wax moth, feed them with wheat bran as supplementary food and feed them with polyethylene film for 2-3 days, and then do fasting treatment. After 24 hours of fasting, immerse the larvae in 75% ethanol to sterilize for 1 min, and then rinse them twice with sterile saline , dissected on a clean bench to obtain intestinal fluid. Put the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com