Method for synthesizing metal organic framework material macromolecule polymer film

A high-molecular polymer and metal-organic framework technology, which is applied in the field of synthesis of metal-organic framework material high-molecular polymer films, can solve problems such as brittleness, energy-consuming production process, and poor stability of MOFs films, achieving excellent performance, The effect of short reaction time and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

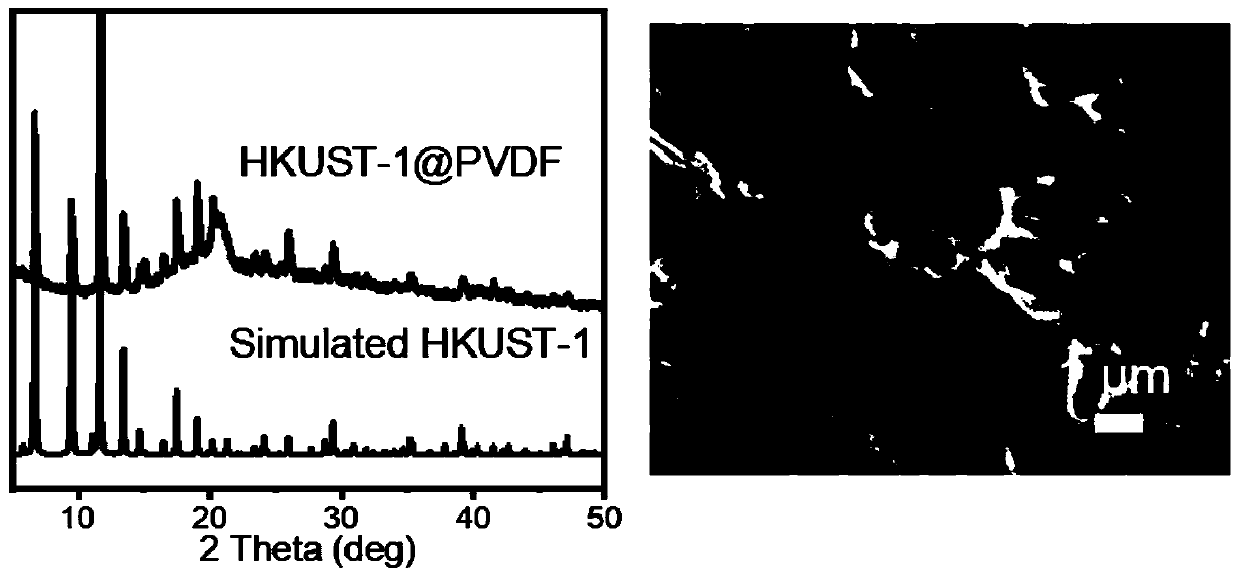

[0029] At room temperature, add 1.4g PVDF powder, 10mL DMF solution, 2ml of DMF solution of 0.1mmol / mL copper nitrate trihydrate, 8ml of DMF solution of 0.025mmol / mL trimesic acid in a beaker, and put the mixed solution at room temperature Stir evenly, then apply it on the glass substrate and transfer it to an oven, keep it at 120°C for 30 minutes, after it is naturally cooled to room temperature, peel it off and soak it in ethanol for several times, then dry it in vacuum at 60°C to get the film HKUST-1 @PVDF.

[0030] The structure of the obtained HKUST-1@PVDF film material was analyzed by X-Ray powder diffraction (PXRD) ( figure 1 ); use scanning electron microscopy (SEM), transmission electron microscopy (TEM) and high-resolution transmission electron microscopy (HRTEM) to analyze the size, morphology and microstructure of the obtained thin film HKUST-1@PVDF material, and use SEM to calculate the HKUST -1 is about 64nm in diameter.

Embodiment 2

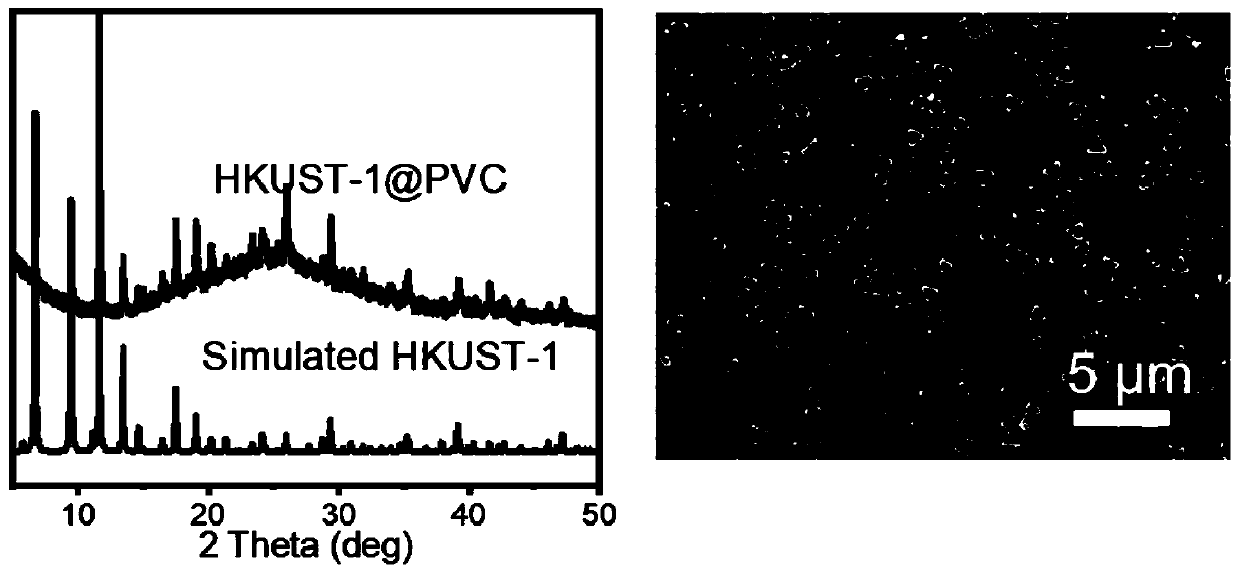

[0032] The preparation process and steps in this example are basically the same as the above-mentioned Example 1, the difference is: the polymer used in this example is PVC, see figure 2 .

Embodiment 3

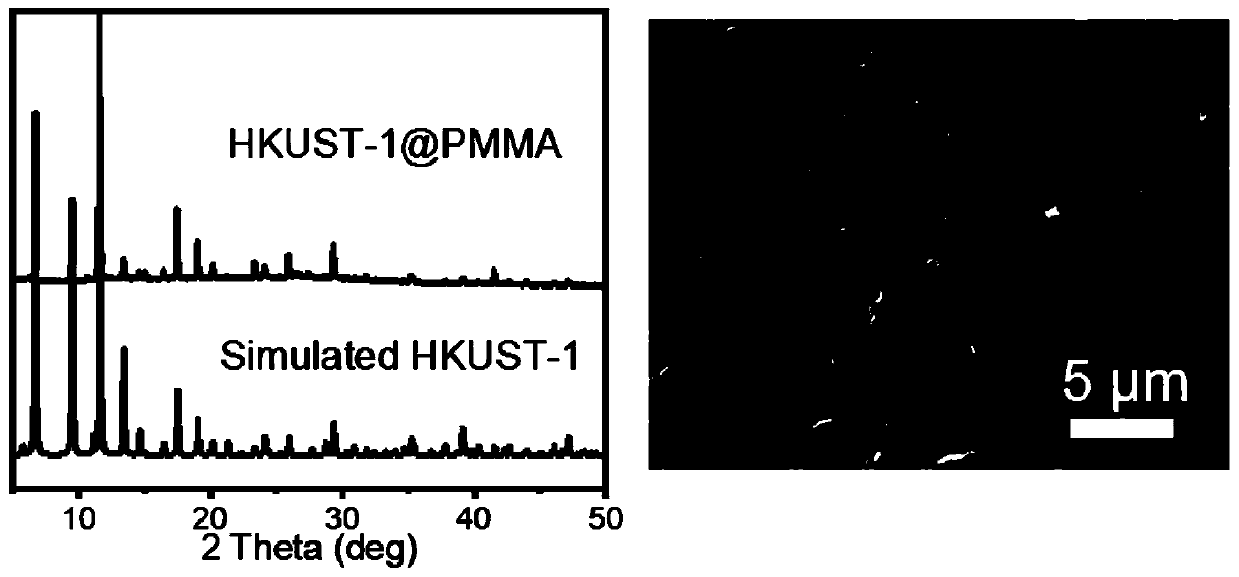

[0034] The preparation process and steps in this example are basically the same as those in Example 1 above, except that the polymer used in this example is PMMA, see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com