High-strength strain-sensitive polyvinyl alcohol ion hydrogel sensing material, and preparation method and application thereof

A technology of polyvinyl alcohol and sensing materials, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement devices, etc., can solve the problems of poor strength, toughness and strain sensitivity, and achieve the improvement of mechanical properties and high strain sensitivity coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of a polyvinyl alcohol ion PVA-Glycerol-NaCl (PGN) high-strength hydrogel sensing material of the present embodiment comprises the following steps:

[0036] (1) Add 2.4g of 1797 type polyvinyl alcohol (PVA) to 20g of a mixed solvent composed of deionized water and glycerol (Glycerol), then stir at 100°C for 2.5h to completely dissolve the polyvinyl alcohol to obtain PVA-Glycerol mixed solution; wherein: the mass ratio of deionized water and glycerin is 4:6.

[0037] (2) Transfer the PVA-Glycerol mixed solution obtained in step (1) to a cylindrical mold, and cool it at -20°C for 12 hours, take it out after the cold treatment, and thaw it at room temperature for 3 hours to obtain the PVA-Glycerol hydrogel Glue; Wherein: described cylinder mold height is 50mm, and bottom surface diameter is 3.5mm.

[0038] (3) The PVA-Glycerol hydrogel obtained in step (2) was fully soaked in a saturated sodium chloride (NaCl) solution for 2 hours to obtain a PVA-Gl...

Embodiment 2

[0040] The preparation method of a polyvinyl alcohol ion PVA-Glycerol-NaCl (PGN) high-strength hydrogel sensing material of the present embodiment comprises the following steps:

[0041](1) Add 3g of 1797-type polyvinyl alcohol (PVA) to 36g of a mixed solvent composed of deionized water and glycerol (Glycerol), and then stir at 95°C for 2.5h to completely dissolve the polyvinyl alcohol to obtain PVA - Glycerol mixed solution; wherein: the mass ratio of deionized water and glycerin is 7:3.

[0042] (2) Transfer the PVA-Glycerol mixed solution obtained in step (1) to a cylindrical mold, and cool it at -20°C for 15 hours, take it out after the cold treatment, and thaw it at room temperature for 2 hours to obtain the PVA-Glycerol hydrogel Glue; Wherein: described cylinder mold height is 50mm, and bottom surface diameter is 3.5mm.

[0043] (3) The PVA-Glycerol hydrogel obtained in step (2) was fully soaked in a saturated sodium chloride (NaCl) solution for 2 hours to obtain a PVA-...

Embodiment 3

[0045] The preparation method of a polyvinyl alcohol ion PVA-Glycerol-NaCl (PGN) high-strength hydrogel sensing material of the present embodiment comprises the following steps:

[0046] (1) Add 6g of 1797-type polyvinyl alcohol (PVA) to 50g of a mixed solvent composed of deionized water and glycerol (Glycerol), and then stir at 100°C for 4 hours to completely dissolve the polyvinyl alcohol to obtain PVA- Glycerol mixed solution; wherein: the mass ratio of the deionized water and glycerin is 3:7;

[0047] (2) Transfer the PVA-Glycerol mixed solution obtained in step (1) to a cylindrical mold, and cool it at 0°C for 24 hours, take it out after the cold treatment, and thaw it at room temperature for 2 hours to obtain a PVA-Glycerol hydrogel ; Wherein: the height of the cylinder mold is 50mm, and the diameter of the bottom surface is 3.5mm.

[0048] (3) The PVA-Glycerol hydrogel obtained in step (2) was fully soaked in a saturated sodium chloride (NaCl) solution for 4 hours to o...

PUM

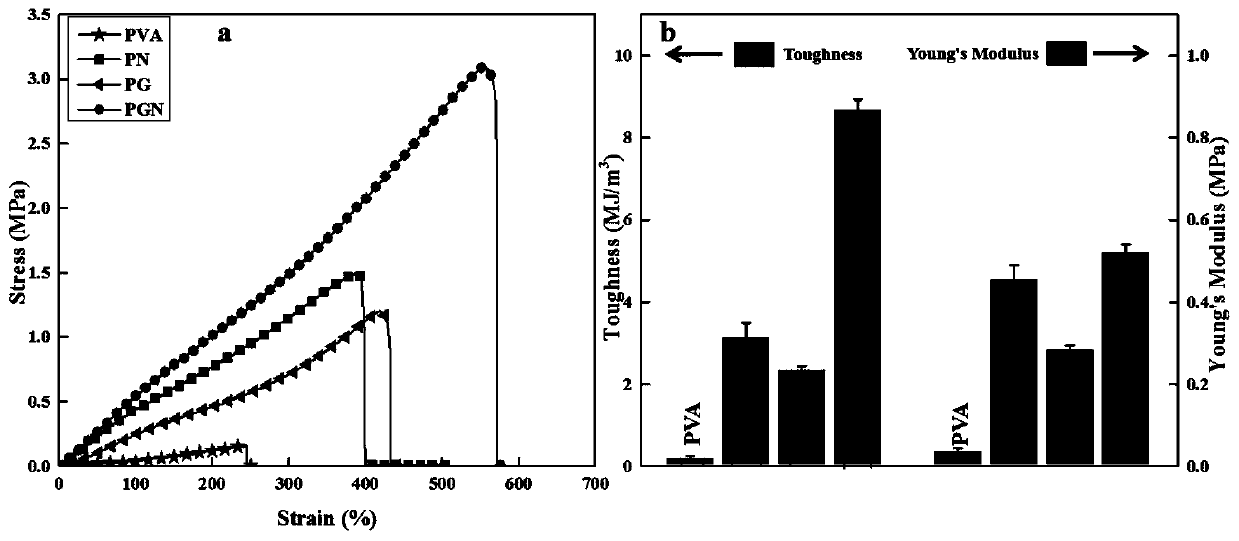

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com